I was born next to a wood stove. I'm from the generation where the kitchen stove and furnace burned wood.

The lights went out before bedtime and morning resumed to start a new fire in order to melt the ice that had filled the containers with water and then to prepare lunch. This was also the time when young, I followed my father to the forest to cut wood (with ax or "bow saw"), bring back the log with horses, cut the wooden logs with the first engines gasoline, split with an ax, store in the "shed" for the winter and then bring it to the wooden box.

Credit :

There was nothing heroic about it: everyone did and it was the only way to heat the house.

Then, the oil and electricity released the man of all these tasks providing a constant temperature even when we are not at home. How wonderful and what a liberation! But can we forget the warmth of a wood fire? The flames dancing and illuminating the floor in the dark, creating shadows on the walls?

In my thirties, building my house, I had the nostalgia of these lights: two fireplaces and a wood stove for supplemental heat ... in case of power failure! I had the wood and ... childrens!

Now retired, having no taste for all these tasks, not so much wood available on my land and becoming environmentally conscious, I wondered how to keep the flame and heat my stove and my home.

Would it be possible to create a low-cost gadget that can burn fuel without changing my wood stove, one that could be effective, reliable, safe and environmentally friendly?

It became a project.

I searched for hours on the Internet, draw more than 50 prototypes, spent weeks of observation in front of my stove, analysing the fire moods. I finally got a solution that meets all these criteria.

My project : Heat

- with a clean fuel

- available

- ecological

- without changing my existing facilities

- without electricity

- interchangeable

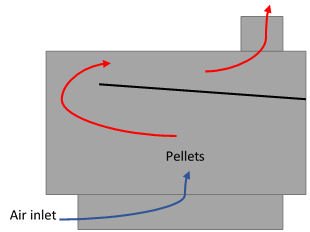

Having a stove with an air inlet in the ashtray, I found that the movement of air from the ashtray was sufficient to activate the combustion of pellets. In sum, the air draft of the chimney replaces forced air.

By varying and controlling the opening of the air inlet, I could vary the combustion intensity. I also found that unlike a wood fire, combustion takes place from top to bottom. Combustion is more uniform and the product gases are immediately burned.

So I got the idea to build a module that can burn pellets ... no electricity, no change of pan without cost and, as a bonus, the opportunity to return in a few minutes, the wood heating.

My first models were made of metal such a basket. None survived. So what can we use as material that is readily available at the hardware store? Firebricks.

Thus, the module or core firebrick serves as wood pellets tank and as a combustion chamber.

The grid

The grid is the base element. It allows both to prevent the wood pellets to fall into the ashtray and to let the primary air flow. As the main air inlet comes from the ashtray, I used three bricks 1.25 inches thick cut in half lengthwise, giving 6 inches 3/16 spaced pieces placed on the wire rack.

Combustor

All available space can be filled with refractory bricks which accumulate heat during combustion and that the return slowly after. The bricks are placed around the grid so as to create a container which can receive the wood pellets.

Finally, as the assembly is simple, it is also easy to disassemble. I can well spend heating wood pellet heating and vice versa within minutes.

Ignition

The granules hardly burn outdoors. It is therefore necessary to open the air inlet from the ashtray, use a starter, such as alcohol to melt and then reduce the air inlet when the flames cover the surface of the granules.

Caution

If you ever want to try it, know that it must be a little handy and know your device. Before you embark on your first start, be sure to carefully read the following warnings.

Thermometer

Use a chimney thermometer installed according to the manufacturer's instructions. You will track well all combustion stages. Inadequate combustion will produce creosote and danger of fire. Burning too much produce overheating thus danger of fires and damage to your facilities. You will have to make adjustments to changing temperatures.

There are two types of thermometers: for single chimney walls, and thermometer with probe for double wall chimneys.

Mittens fire

Once you are loading or cleaning your stove, use mitts or heat resistant gloves. Firebrick retains heat for several hours. Be cautious, avoid burns!

Opening the door

As soon as you turn on your device, do not open the door during the burning time. Two reasons for this caution:

- Thermal shock on the bricks that can cause harm: breaking, cracking, bursting, etc.

- During combustion, especially in the second phase, the massive entry of air can lead to the extinction of the flame. Gases accumulate in the room and if the flame is slow in coming, there may be an explosion. Also, for periods of high winds and gusts, an inversion of the draft in the chimney can cause the extinction of the flames and produce the same result.

Loading

Never add wood pellets on hot coals without a direct ignition. These will produce gases which will not be immediately burnt. When the flame will appear, there will be an explosion that could be dangerous.