The curious world of a tinkerer.

Trouble with machines are one reason to start being creative.

Numerous times I have found out, that people don’t really know what an engineer does, or have a wrong picture all together.

You’re an engineer? Than you can build me a helicopter right? Or make my car park sideways!

True is that not all engineers are in construction and development. In the last article, Why Engineering, we pinpointed the area of expertise being roughly in the transition from science to manufacturing. No matter where in this area, the engineers still have to do the following tasks: inventing, cronstructing, tinkering, planing and quality control.

So let go through them.

Inventing

The closer an engineer works to science, the more he might have to invent things. The technologies he works with are right out of the lab and he might be one of the first to put this knowledge to good use.

Inventing thus is the process engineers are most commonly known for. What helps here is the possesion of a healthy dose of fantasy, spatial visualization ability and a solid knowledge in the scientific field.

In inventing, questions are solved like:

- What do I do with all these carbon nano tubes?

- So if i combine titanium with gold I get an alloy of great strength, where can I use this?

All this builds a picture that the engineer can work towards.

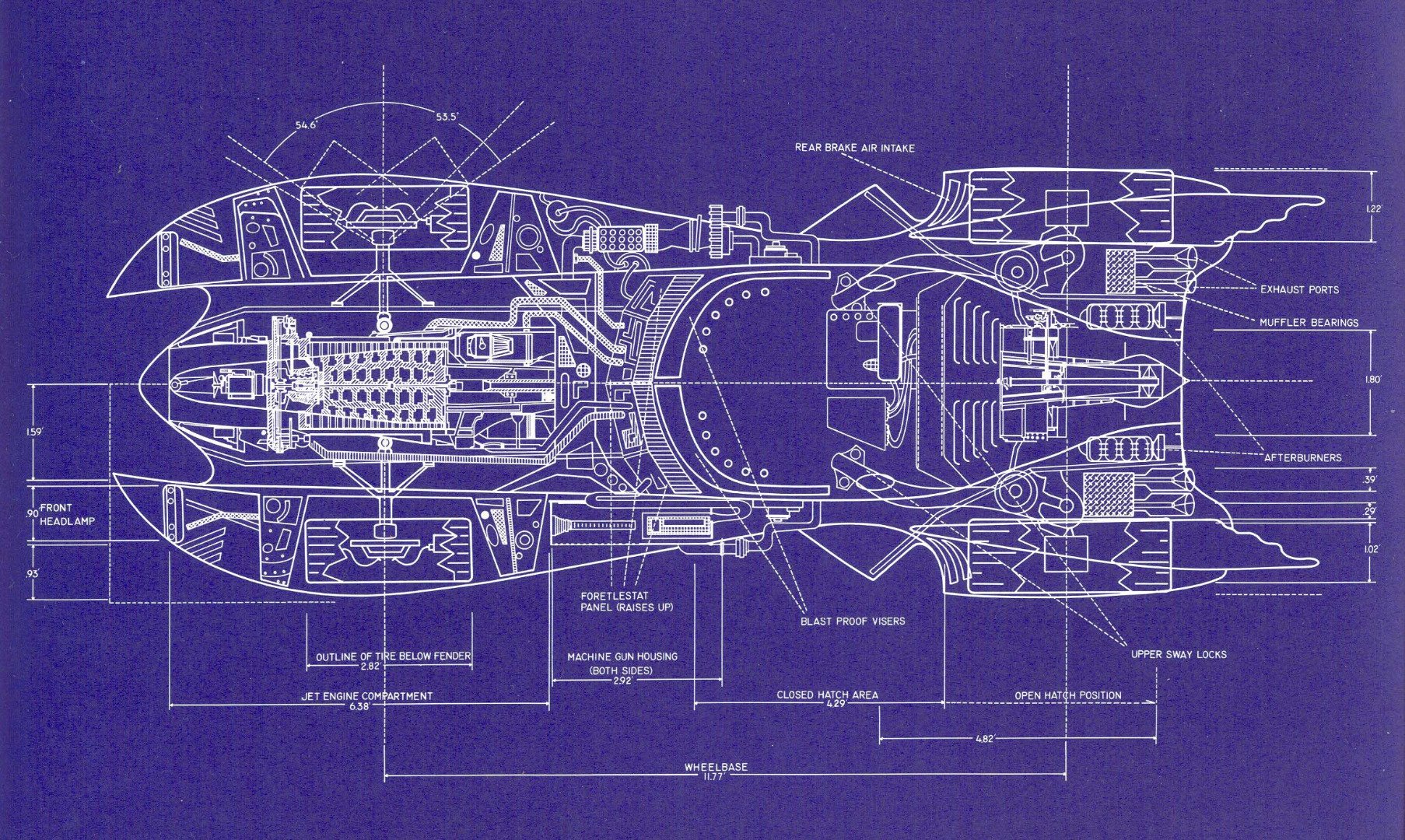

Construction

While inventing basically tries to grasps functions out of thin air to put them to good use, in construction the engineer tries to take what he knows and to combine it to fulfill a goal.

Don’t invent the wheel a second time!

This means that if you want to solve a simple function, use what you know that works. Don’t experiment with unimportant things. There are a lot of elements in engineering that have proven their usefullens:

- Gears

- Screws

- Levers

- Welding

- Materials

- Production techniques

- and of course: wheels

The product that you are building has to fullfill a specific function: brew coffe, drive with electricity, stick to walls or print with plastics. Everything that supports this function should be solved with known solutions so that the focus can be put on the exotic new function. Don't make it more complicated than necessary.

Tinkering

Sometimes, you have to use trial and error. Even today, noone knows how a propeller really works. The unknowns are just to many:

- Air speed total and relative to the propeller

- Rotation speed

- Material density

- Surface friction

- Air and material temperature

- Flowstate

Thus an engineer ends up using the most important factors to estimate what can be expected and then builds some prototypes to test it. He tries different designs, sees what works and then tries to gets the best performance he can get.

This led to ships still using the same propeller design like a few hundret years ago. The same principle is used for turbines aswell. Afterwards it is the work of engineering graduates to find out why it works.

Trial and error is an important part of engineering and can save a lot of money. Today this is very easy to do, because a product can quickly be produced via rapid prototyping (3D printing) and virtually simulated.

Planing

When the product is constructed,the engineer has to have two things in mind that decide the the direction of the work:

- How will the product be build

- How will the product be used, this includes disposal too.

Production planing and lifecycle planing keep the construction focused on the important questions if the product is possible to build and if someone can use it. Quite important if someone aims to earn money with this craft.

The importance here is to find the balance: to much planing makes you inflexible to react to problems. It will be hard to change the plan. If the plan is to losely planed, you might not know where you are going. Wrong decisions might be made because it wasn't clear if they fulfilled they bring the product closer to its target.

Qualitycontrol

All this tasks are skills, honed over time and perfected. But to really get things running smooth, quality control offers tools to work as efficient as possible.

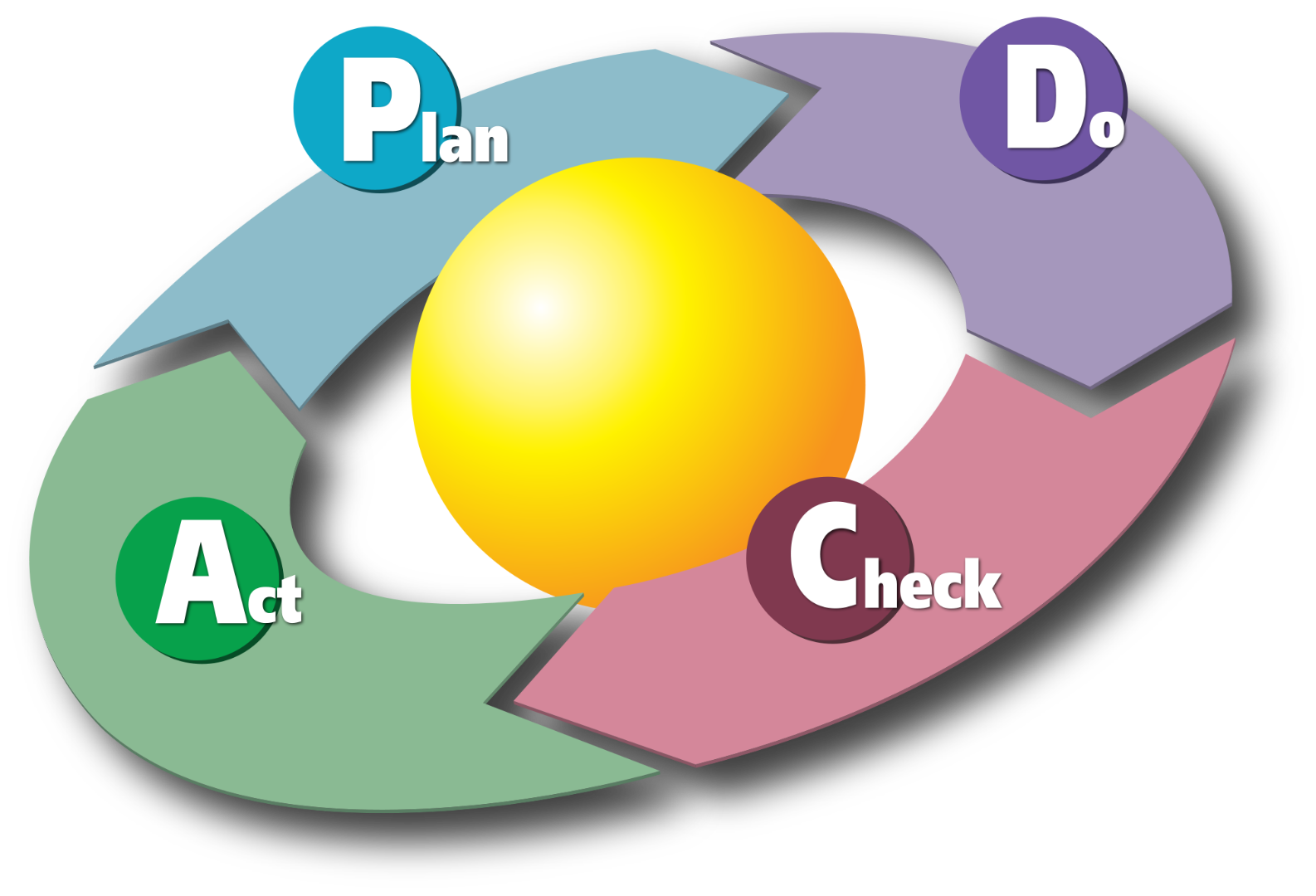

Continuus improvement: Plan what do you want to do. Do it and gather data. Check the results with your plan. Act by making adjustments that bring you closer to your plan the next time.

Quality here means not that the product is the most sturdy or most cost efficient: The quality increases with the amount of abilities of the product, that align with the needs of the customer, known or unknown by him.

“Quality is never an accident. It is always the result of intelligent efford.” — John Ruskin

A plastic spoon has a high quality if the user desires a lightweight, very cheap, but durable eating device. No need to build a spoon that will last centuries when the patron is happy to discard of his cutlery after the meal.

The continuus control of quality is therefore important to keep your tasks aligned towards your goal, and to find your goal it is important to know exactly what the customer actually wants from you.

This will be discussed in the next chapter, where the goal setting and building of necessary framework is layed out.

Thank you very much for reading!

To be continued