Created on canva.

Greetings dear friends,

How are you all my friends? I hope all of you are well by the grace of Almighty Allah. Alhamdulillah I am also well by the grace of Allah. I am also well by God's grace and your love. Today I am here with a new chapter about ETP plant. The topic I discussed in Part 2 is How does RAW waste water enter in the ETP plant and what is screening & how does it work?. I will discuss today in my second part how the ETP plant equalization tank requirements and how the wastewater treatment process works from there. process and many more things. So let's start.

For purification of waste water, solid waste is first separated from waste water through screening and then the place where this water is collected is called Equalization Tank. The function of equalization tank is to equalize the water. Different types of water comes from several dyeings of the company at the same time and this waste water is kept in the equalization tank to equalize the DO, Ph, TDS, Tem in the water. We can call it the main tank for storing waste water. The total water holding capacity of this equalization tank of our ETP plant is 2000 m^3. And our ETP plant can purify 180 m^3 of water per hour.

Here air blower machine is used to increase DO in equalization tank. The pipes of the air blower machine extend to the bottom of the tank where air is supplied to the equalization tank and all other tanks through a certain pressure.We have a total of three air blowers here, each blower is connected to the air blower pipe. Air blowers are changed every 12 hours. And 2 new air blowers are being installed in our plant as backup so that we can use the others if there is any problem.

|  |

|---|

After the water reaches the equalization tank, the next stage of water purification starts from here from this tank we have to start all the water testing. Here all the tests we do regularly from water are Dissolved oxygen (DO), Power of Hydrogen (PH), Total dissolved solid (TDS) & Temperature(Tem). And each parameter has a specific value. And this value accordingly we have to start the process of purification of this water so the water of this equalization tank (which we also call inlet water) has to be checked daily. We check this waste water three times in 24 hours.

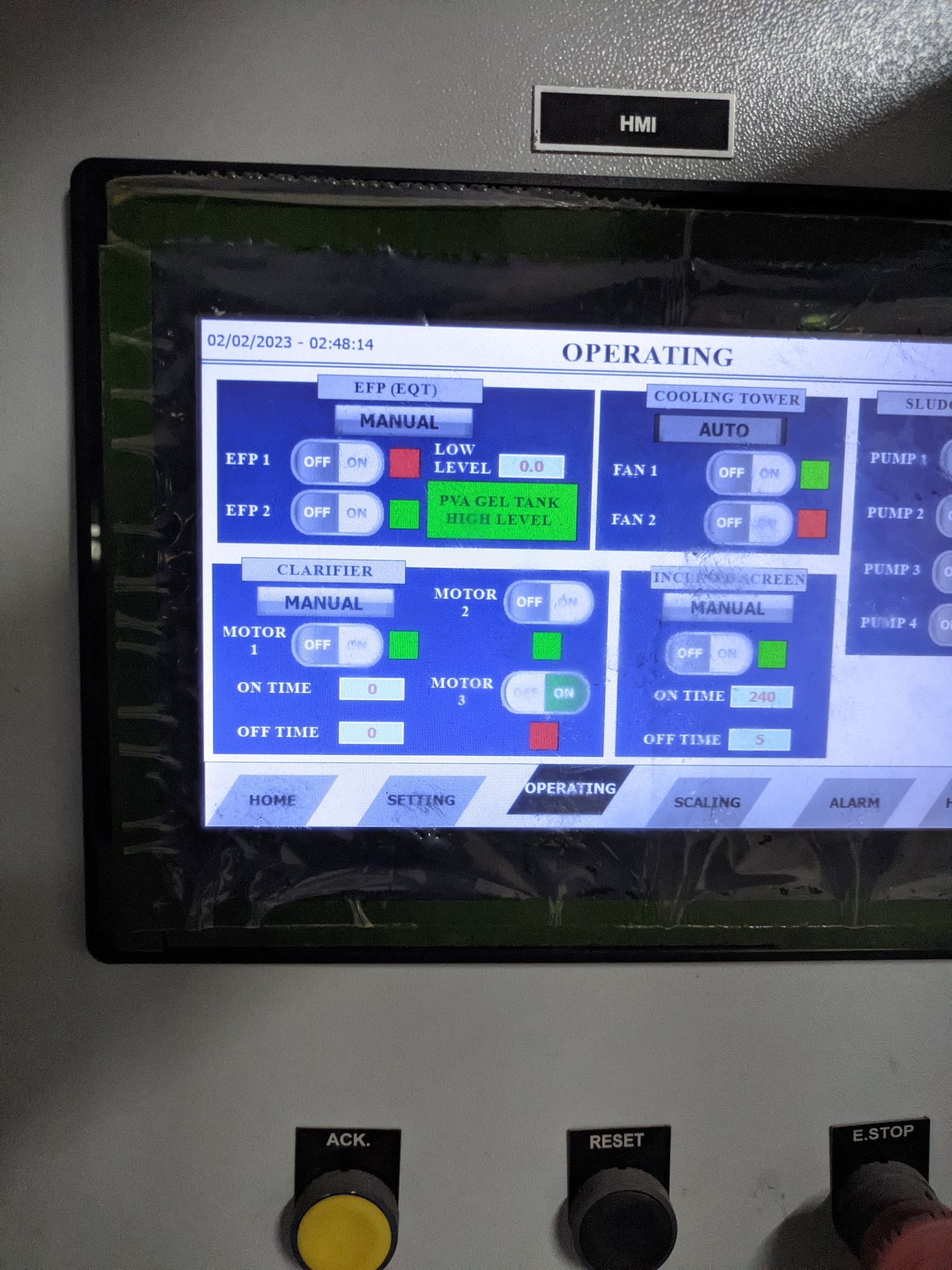

Since the water is treated 24 hours a day, this water is pumped from the equalization tank by pump. And this pump is called Effluent Transfer Pump (which we also call feed pump. We have two feed pumps here and these two pumps are running regularly. And each pump is changed every 6 hours.

|  |

|---|

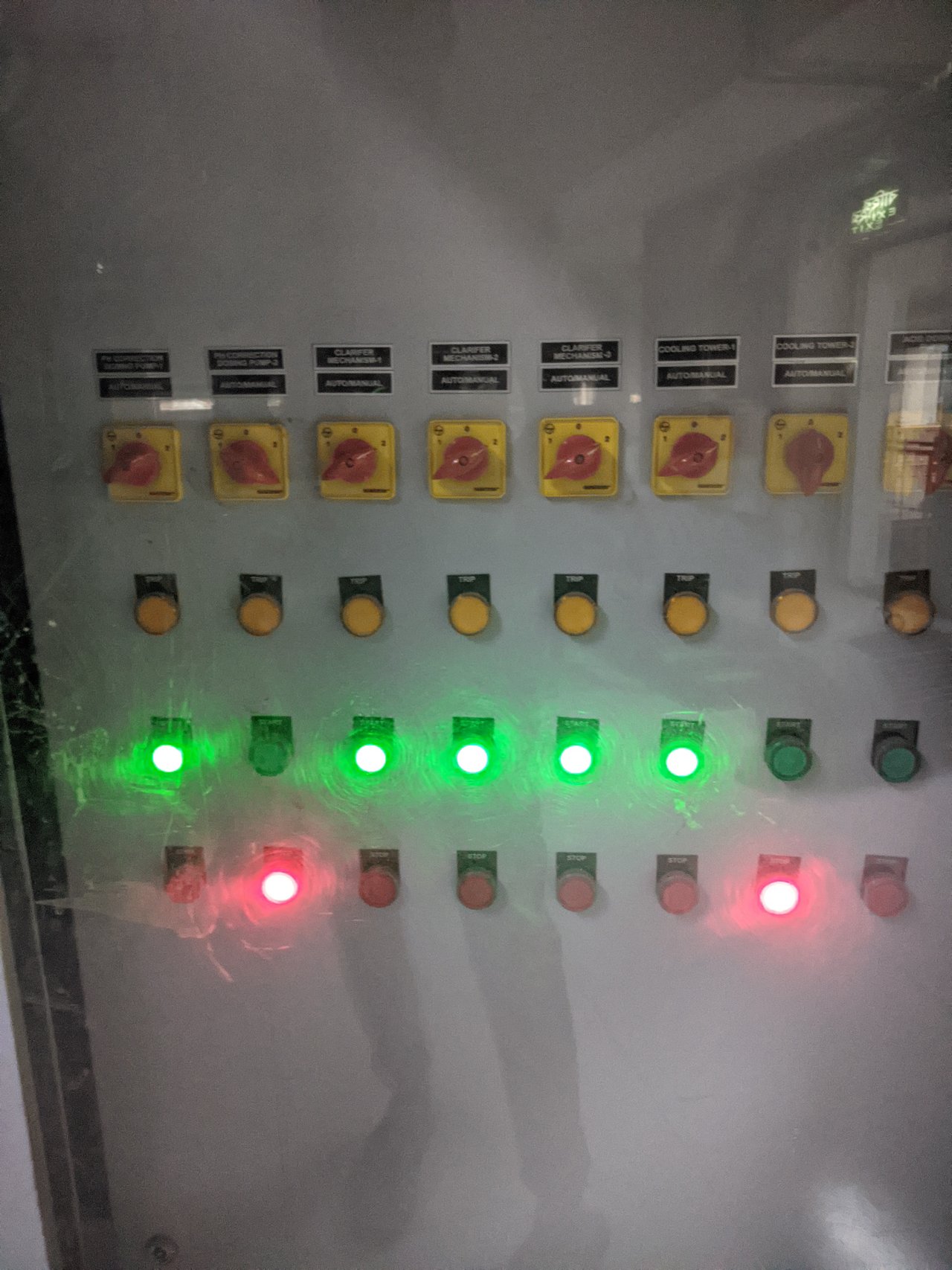

And we control this pump from the control room of our ETP from there we can control it manually or through auto mode and there is panel board to setup them. And if there is any problem with the pump, it is reported immediately. It is given to the maintenance room and they immediately send people to repair it.

So, dear friends, these works are done daily from the equalization tank for water purification. Hopefully you have got a detailed idea about the equalization tank after the post.That's it for today. In the next part, I will discuss the next step in the ETP plant's water purification process. Till then stay safe, stay healthy. Have a good day.

@ steemcurator01 @ steemcurator02

@ pennsif