There are two power tools I find essential for homesteading in a non-urban, rural environment. For sure, you could make do without these two tools, but the speed of which jobs can be accomplished with their use, lends so much more free time to devote to other projects they're almost a necessity. The first tool necessary on the Good View Quarter is our Yanmar 2000D, and since I have near zero interest in learning, training, buying and keeping horses, tasks such as mowing the lawn, plowing the garden and skidding logs requires mechanical horses.

The second tool vital to our little Quarter is a chainsaw. In fact, if I think hard enough I might say the chainsaw is a more vital tool than the tractor. Imagine clearing a pasture, or cutting cords of wood for winter with a bow saw? I love Gramps and his hard working way of life, but I think I'll pass. Bucking, splitting, and stacking give my hands enough callouses.

While a tractor and a chainsaw are quite different – one runs on diesel, the other two-stroke, one is bigger than a car, the other can fit in a car – they do have a few similarities. The most obvious is upkeep: all power tools need maintenance. Consider it the feeding of the horses. The tractor needs new filters and fluids; the chainsaw needs cleaning and sharpening.

In the same way that I deferred discussing tractor purchasing specifics, I will defer on the chainsaw as well. (To be clear, I am no chainsaw expert but my tech-ed teacher-brother also runs a tree removal business, and I hope to have him write a blog post detailing the specifics.) That said, there is one commonality across chainsaws, and that is the need for a sharp chain. The chain is essentially a blade and if you've ever used a dull knife to peel an apple, you know how much work goes into cutting. You also may have learned how dangerous it can be to force a dull blade. The same is true of a chain saw: a dull chain or blade will work, but it takes more effort and taxes the motor more: shortening it's life span. It also requires the operator to use more force which can lead to more accidents. This is no good. You need a sharp chain to keep your motor from overworking and to keep the operator safe.

So how do we keep a chain sharp? There are essentially two answers. The short easy answer is the blade sharpening handy man down the road. You can price your own out, but every guy I've asked has wanted $7 a chain. Granted, $7 isn't a whole lot, maybe a lunch at McDonald's, but consider that you ought to sharpen your chain every 3-4 tanks of gas. If you're cutting wood for winter's heat, four tanks will be gone before you know it and you'll start racking up that $7 bill, not to mention the time it takes to get the chain to the guy and wait for it to get sharpened (they almost always want the chain on the bar which means on the saw which means your sawless.) So what do you do? Sharpen it yourself! It's cheaper in the long run, and will save all that driving and waiting time.

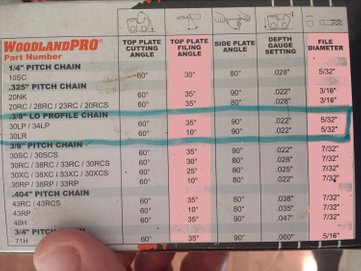

Keep in mind, not all chains are created the same and different chains will take different size files to sharpen them. Generally speaking, there are three common round file sizes and a kit containing all three of these sizes, plus a flat file, a filing guide, and a depth gauge can be had for about $20. You can also buy a round file individually should you (or your kids or your neighbors) break or misplace the size you need.

.

With your saw situated and your chain marked, you're almost ready to go. This is where you'll need to remember that filing angle number (mine is 35°). Look down at the top of the filing guide and you'll see a bunch of numbers and lines. Find the correct angle for your chain. You want to align the appropriate angle line parallel to the bar of your saw. Place your file between the gullets of the teeth, make sure the flat side of the file guide is flush against the chain tooth (this should make a 90° angle with your bar). Now recheck your file guide angle and push the file away from you; never pull the file toward you, always away, always. The number of strokes you give each tooth, will depend on a variety of factors.

Give your first tooth however many strokes you find appropriate remembering to remove the file from the gullet of the tooth on the back stroke so as to not round over your newly sharpened edge, and then move to the next tooth facing towards you. Notice you skipped a tooth, when we're all done with this side, we'll flip the saw around and do the teeth that were once facing away from you.

If you're not sure how you did, check out your sawdust next time you cut a log. A sharp chain will leave nice big, long chunks of saw dust, a dull blade will leave small sawdust chunks. A dull chain may also tend to drift while you cut. This happens because some teeth are sharper than others, and you're once vertical cuts will start to have more of angle to them. The worst that can happen when sharpening a chain is that you do it wrong, and if you do that, you take your chain to the sharpener guy and give him $7. (There are also some seasonal sharpening/chain-checking things that need to happen. But we'll get to that another time.)

Good luck and remember:

- Mind your file angle

- Never pull the file towards you

- Keep your angles and strokes uniform

- Stay out of the dirt!

https://discord.gg/hPJs5Rb