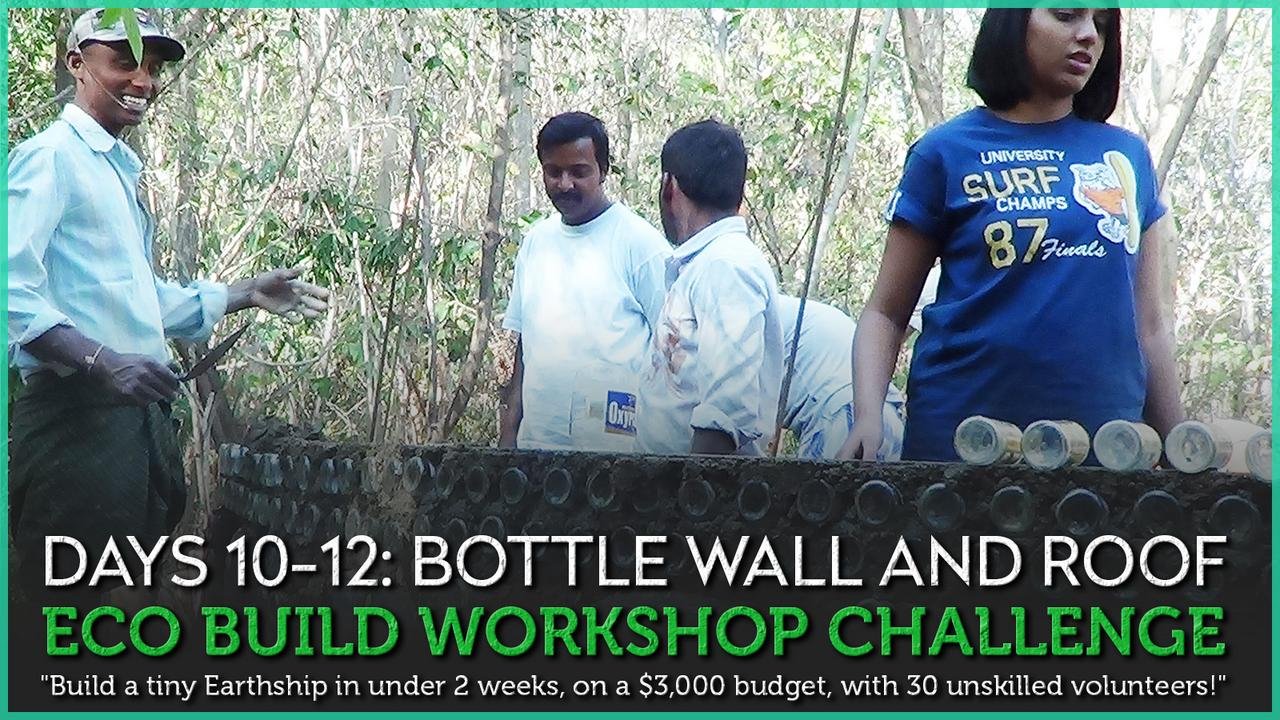

Suddenly we are on the final leg of the build! It's amazing how the last 5 days just whizz by, but we are in a good flow and everything is taking shape! On days 10-12 we focused on finishing the main walls of the Earthship with glass bottles. We couldn't get enough tyres on short notice, and I was very happy to shift the last few days efforts from tyre ramming to bottle work. This meant that we could work even faster and get the roof on before the end of day 12. That would leave us two more days for the maisoners to plaster the ferro-cement roof frame that we had made, whilst the volunteers finish plastering the main walls on the inside and outside.

Day 10:The Start Of The Glass Bottle Wall

The final tyre was pounded in the morning, and we were ready to start finishing the main walls using small glass bottles. A few people washed the bottles with water so they they would look perfect once they were finished. There are different ways to use glass bottles when building. If you are making a non-load bearing wall such as a partition wall then you can make it quite thin and allow light to pass though. To achieve this, you need to cut the bottles and make a bottle brick using two base ends that are taped together. You can get the idea from this image:

Since we were making a load bearing wall, the main material was in fact concrete, with the glass bottles forming a decorative skin to contain it all. The work is quite easy but attention to detail is very important.

The most important factor is the positioning of the glass bottles whilst you lay them with cement. They do need to be positioned very accurately so that they look nice at the end. Once the cement sets you cant change it, and so I was very attentive whilst people were adding more bottles. You can get a good idea of the process from these images.

Adding concrete and stones to the center

This was fun work, and many people could do it at the same time. We all spread out around the main wall, and added bottles and cement. My job was mainly checking the position of the bottles, and I basically walked around all day, had a little chit-chat with whoever was working, and nudged each bottle slightly. It was useful to have a good maisoner on hand to help and make sure the mix was correct and put on well. We were in the flow in no time, and I think we were all happy to do some detail work rather than the hard grunt of pounding tyres all day.

It always looks a bit rough until the final plaster is added, but I could see it was going to look really nice and I had even managed to integrate a simple but pleasing design as you will see next time for the big reveal!

Day 11: I Killed The Web Sever!

As some of you will know, I finance my life and subsidized this project using money that I made as a web developer. This has been how I have made money most of my life, and I have been very lucky to be able to keep the same job whilst working remotely for several years. My job is with a company based in London, and they always keep me on my toes with sudden and urgent work. We have hundreds of websites that I have created over the years, all hosted on a web server that I managed. This web server was the lynch pin of their whole operation, and if anything ever happened to it, there would be a major problem. Whilst we were all working on the glass bottle walls, I got an email on my phone asking for some files to be copied on the server. It was an easy enough request, and one that I could just about pull off on my mobile phone using SSH to send commands to the web-server. I had to issue a command to compress a folder so that I could easily copy it to the new location where I would decompress it and the job would be done. I had forgotten the exact command as they are not written in plain English and Googled it quickly before typing it in using my tiny mobile phone keyboard. I hit enter and off it went. Normally this process takes a few seconds as there weren't many files to copy, but as I looked the page was scrolling at light speed showing me an endless list of files that it was compressing. I could hardly read them they went so fast, but it was clear that I had done something wrong as it seemed to be compressing other files as well.

My heart dropped into the pit of my stomach, and I'm sure my expression was priceless. "OH MY GOD" I blurted out, as it started to dawn on me what was actually happening! "I have to go!" I ran to my room whilst my eyes were glued to the screen watching still more files being compressed. What was happening was probably the most terrible thing that can happen. The server was compressing EVERYTHING into TAR files AND also deleting the original. This meant that the whole server was about to grind to a very abrupt halt and also Every single website and email account was going down. To make matters worse we didn't have a reliable backup since there were SO many websites on the machine that it broke the backup system. (this has been resolved now ;)) . Everything was potentially totally screwed, and it would take me weeks of 10 hour days to put them all back from my local machine.

These heart stopping moments are ones that we never forget. Thank God I was VERY lucky, and I Googled the command to decompress everything and delete the TAR file. I really wasn't sure if the command would work properly, especially since even system files were gone! I just prayed, HArd, and pasted the command into the SSH prompt. It kicked off straight into action, and at least LOOKEd like it was working. It took AGES, like an hour or more for the process to complete. I was successful, and in the space of two hours went on a roller-coaster ride that no-one would want to experience!

By the time the dust had settled, it was almost the end of the day, and I ran back to the build to see how the progress was. Leaving 20 volunteers with concrete and major work to do is also not such a great idea, but thankfully they had worked well in my absence and everything was looking evenly spaced and positioned.

Day 12: The Roof Frame Goes up!

The day had come finally! We were ready to bring the metal frame that we had made to the Earthship and install it on the glass bottle walls. This was not that heavy but was quite flexible if you pushed on it. The metal frame was about 20 feet away and looking at the path it was clear that it would be a tight squeeze as we had two trees that were very close together and we had to pass the roof frame through it. Around 20 of us picked up the frame and we marched it toward the building. As we got to the small gap it was clear we had to stop and rotate the whole thing on its side so that it would fit through. The problem was, most people were just focused on moving the roof and were not even aware of the size problem. Therefore a few of us stopped walking with it, and the rest of the group just continued and started pulling it through the gap whilst I was shouting "STOP!" In the end it did make it through but it got quite flattened and malformed. That was a shame as I had spent a lot of time getting that curve right, but I just had to let go of that idea, and hoped we could fix it back once we got it on the walls.

The good news was the the frame fit on the wall! Luckily it was flexible so we could pull it to fit the the wall all around. This frame was pinned to the wall using U shaped metal rods that were hammered into the wet cement. The cement was still wet enough to do this, had it have dried we would have drilled holes. The roof frame was UP and it suddenly was looking like something! The next job as to get the maisoners to put the first coat of plaster on the structure. The normal way to approach this is to cover the entire roof with rags or old fabric that is dipped in cement and left overnight to dry a bit. This covers all the small holes so that it is much easier to apply the cement without it falling through. It suddenly dawned on me that we didn't have any rags available anywhere on site, and so I had to make a dash to go and try to find a few sacs. We needed a lot, and I wanted a cotton based rags as they would absorb the cement and water well. Therefore I decided to try to find some old second hand clothing which should be just the right thickness and material. I went to a few shops and before too long I found myself in the back of an old home that had nothing much in it except sacs of old clothes. The owners seemed happy I was going to buy so much of it and we made a deal on the spot. It was around $50 for three huge sacs of stuff. It was a real mix of everything from children's underpants to huge Saris. I stuffed them into the rickshaw and we drove back to the site where I unloaded everything and dashed off to meet my partner @clara-andriessen for a late lunch. Thank God I had Clara to keep me watered and fed. I easily miss meals and unless someone is there to make me eat I just carry on working.

When I returned to the site I wasn't sure whether to be angry or amused! The volunteers had discovered the sacs of clothes, and decided to have a fashion show and put them all on. I was hoping to come back to see the maisoners getting busy putting them up on the roof, but instead this was happening:

Spontaneous fashion show with my second hand rags

In the end I saw the funny side of it, and everyone was have such fun... that was until I realized the more than half of the clothes had vanished totally! I had no idea where they went, but quickly realized that the locals had been having a lucky dip and grabbing them! Oh India! I guess I made many people happy that day, and we still had some left thank God. The maisoners got to work, and started dipping the clothes into a thin mix of cement and covered the roof with them.

The rest of us got to work plastering en-masse. We had a lot of plastering to get through and had to do both inside and outside. Once the plastering was done, the build would basically be done since there was very minimal systems since this was going to be a meditation space and not lived in. I did plan to install a small solar system to power a fan that was going to blow hot air out of the skylight, and we also needed to seal the walls to give it a long life and some waterproofing. All this was going to happen over the last two days, and I was confident that we would be able to make it. There would be some finishing work to do, but that was easy to accomplish with a few local workers once all the volunteers had left.

At the end of the day the mood was Very high. We all sat and stared in awe at what we had created, and really all deserved a big pat on the back. It is a great achievement to build something that is so solid and significant in such a short time and almost exclusively with unskilled volunteers. I was feeling very proud and relieved that things seemed to be working out despite my great ambitions. Please join me next time to see the final part and big reveal of Earthship Ananda. I can tell you now, it looks beautiful! ;-)

DID YOU MISS ANYTHING? READ PREVIOUS PARTS HERE

-

My Eco-Build Workshop Challenge. Build a Tiny Earthship in 2 weeks on a $3,000 budget with 30 unskilled volunteers!

-

Eco-Build Workshop Challenge Days 1-3. "Build a Tiny Earthship in 2 weeks on a $3,000 budget with 30 unskilled volunteers!"

-

Eco-Build Workshop Challenge Days 4 - 6: "Build a tiny Earthship in under 2 weeks on a $3,000 budget with 30 unskilled volunteers!"

-

Eco-Build Workshop Challenge Days 7-9: "Build a tiny Earthship in under 2 weeks on a $3,000 budget with 30 unskilled volunteers!"

Thanks for being here with me and the ecoTrain!

We are a small community that support each other because we love what we write.

check our our ecoTrain magazine at @ecotrain

If you love to write, and would like to join the ecoTrain community as an official passenger please email me on steemit.eco.train@gmail.com

** Click Here For More Information on the ecoTrain **