Hey steemers, I would like to share with you the art of screen printing.

6 colour carousel

This is a dying art due to all the automatic screen printing machines and direct to garment printing.

But I am keeping the dream alive and business is good ☺.

I started screen printing in 1997 and in 1998 started my clothing label called VC Clothing.

Check out my website right here --->

http://vcclothing.com/shop/

Hence my steemit name vcclothing 😁

In 2002 I went full time with my screen printing business and have never looked back!

Here is a simple run through of the process of screen printing a shirt with plastisol ink from artwork on your computer to the finished tshirt.

The client is "The Hub Brewery" a micro brewery down the road from my house. They were after a 1 colour front print and a 1 colour back print on work shirts.

Step 1

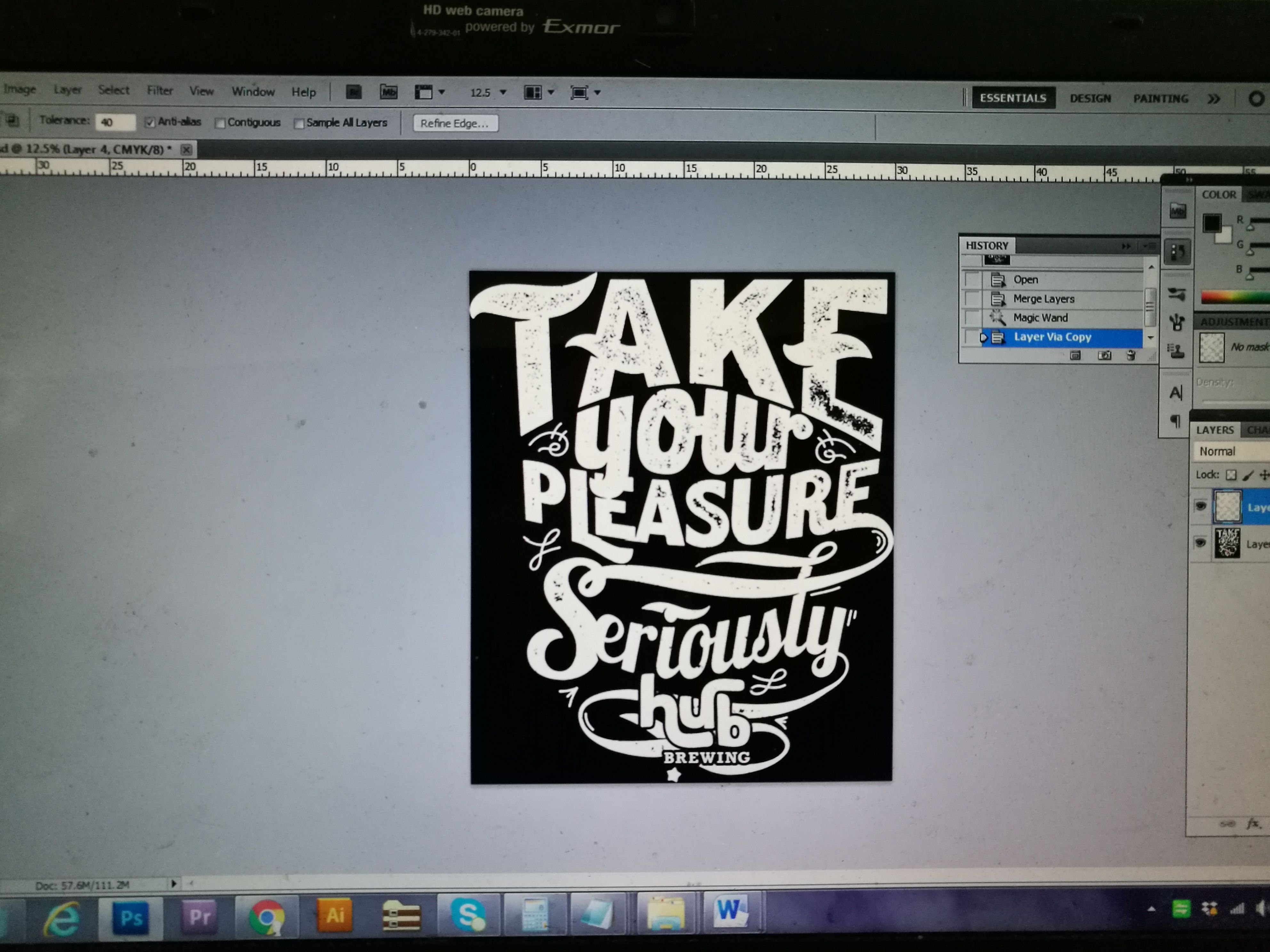

Artwork

Make sure the image is hi resolution and not pixelated.

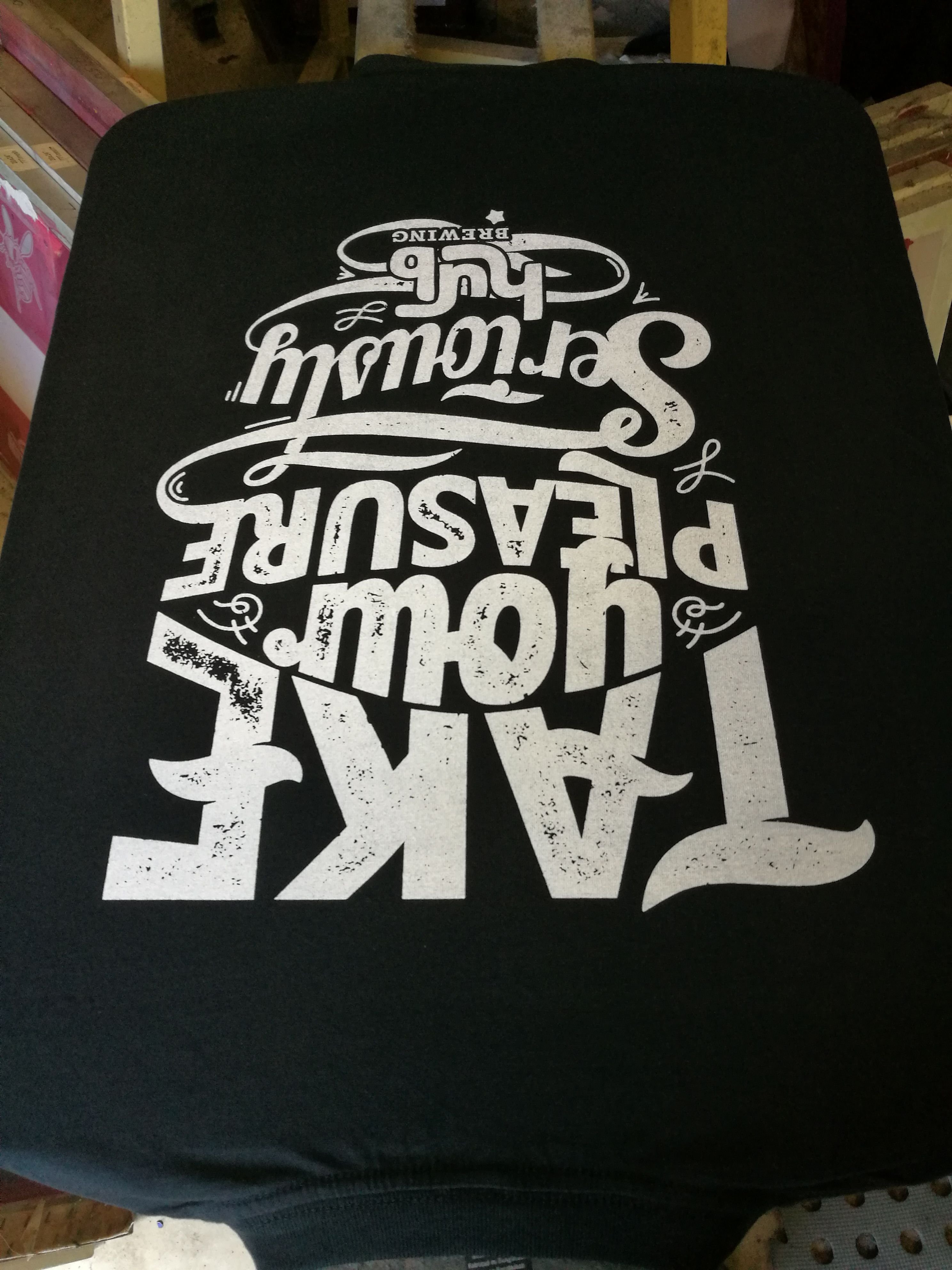

Back of the shirt design

If it is low resolution and pixelated. Redraw the design into a vector, for best quality screen print.

Step 2

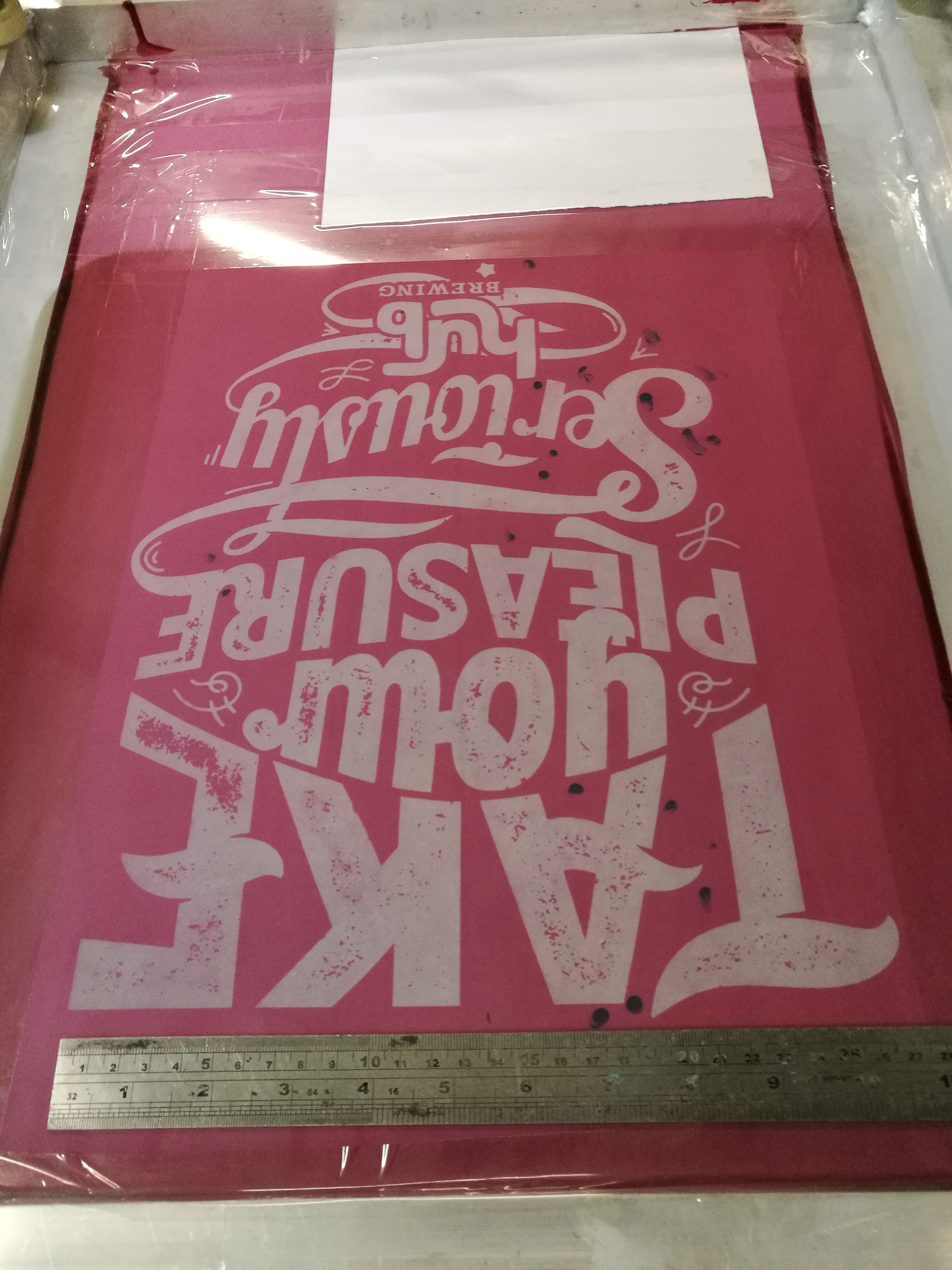

Transparency Film

Print out the design onto a transparency sheet, to use for exposing the screen. The lovely ladies at Snap printing help me out with this.

Step 3

Screen prep.

This design isn't too detailed so I will use a 43T mesh screen.

43T mesh is a courser screen.

43T means that there is 43 threads per centimeter.

Blank 43T screen

Once you have the right screen picked out it's time to coat the screen with emulsion.

Coating tray and emulsion

Emulsion is a photosensitive chemical which hardens under UV light.

Coating the screen with emulsion

Coated screen

When coating the screen make sure you put 2 coats on the outside and 1 coat on the inside.

Once coated, dry the screen in a dark place so no light can effect the emulsion.

Step 4

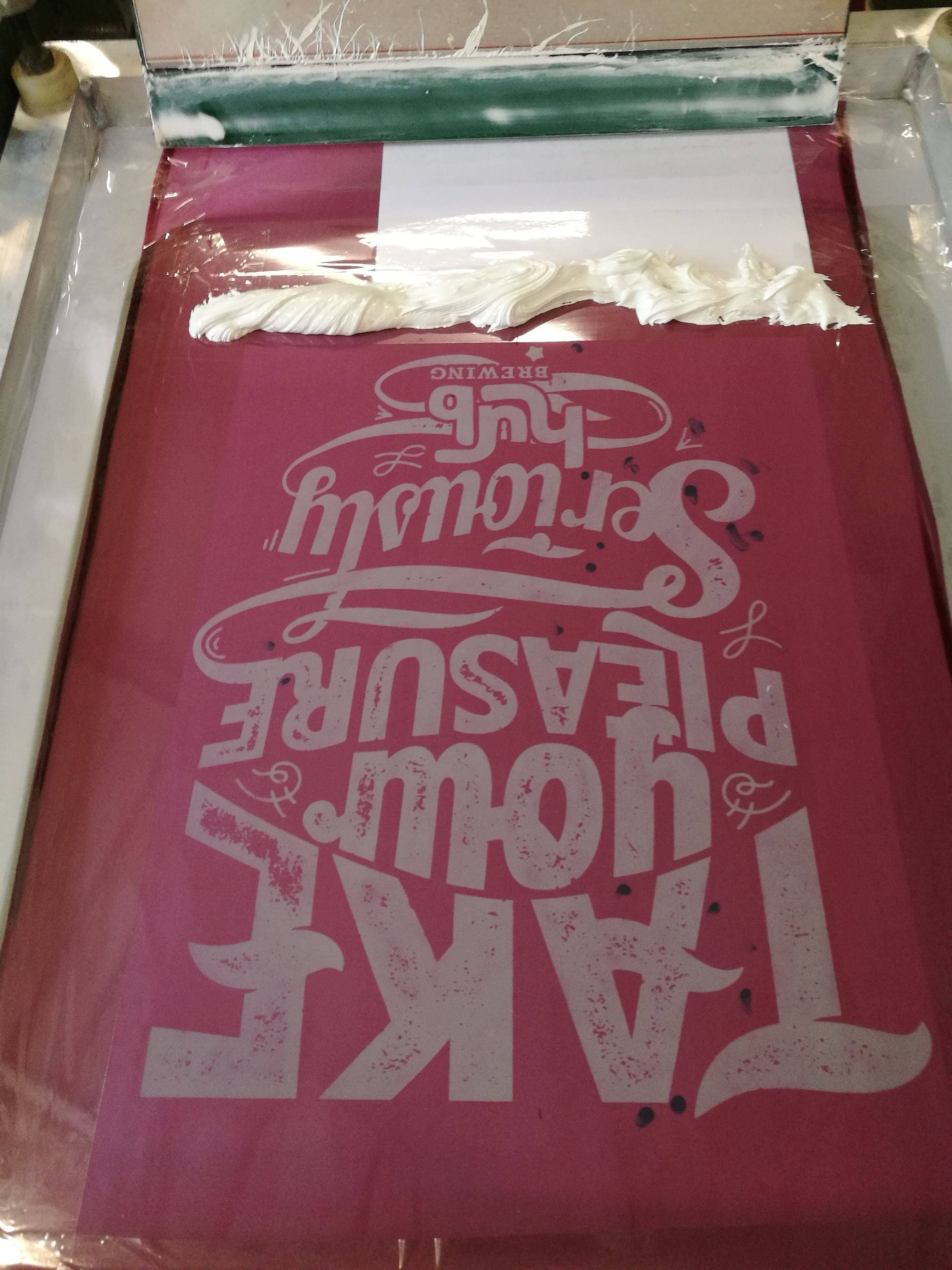

Shooting the screen.

Exposing the screen to UV light

Place the transparency onto the dried emulsion and place the image reversed, so when you print on the inside of the screen, it will be the right way around.

Place a sheet of glass over your transparency, to keep it in place and to disperse the light better onto the emulsion.

Shoot the screen with UV light until the emulsion has hardened. Times vary depending on your light source.

The transparency blocks out the UV light and keeps the emulsion soft.

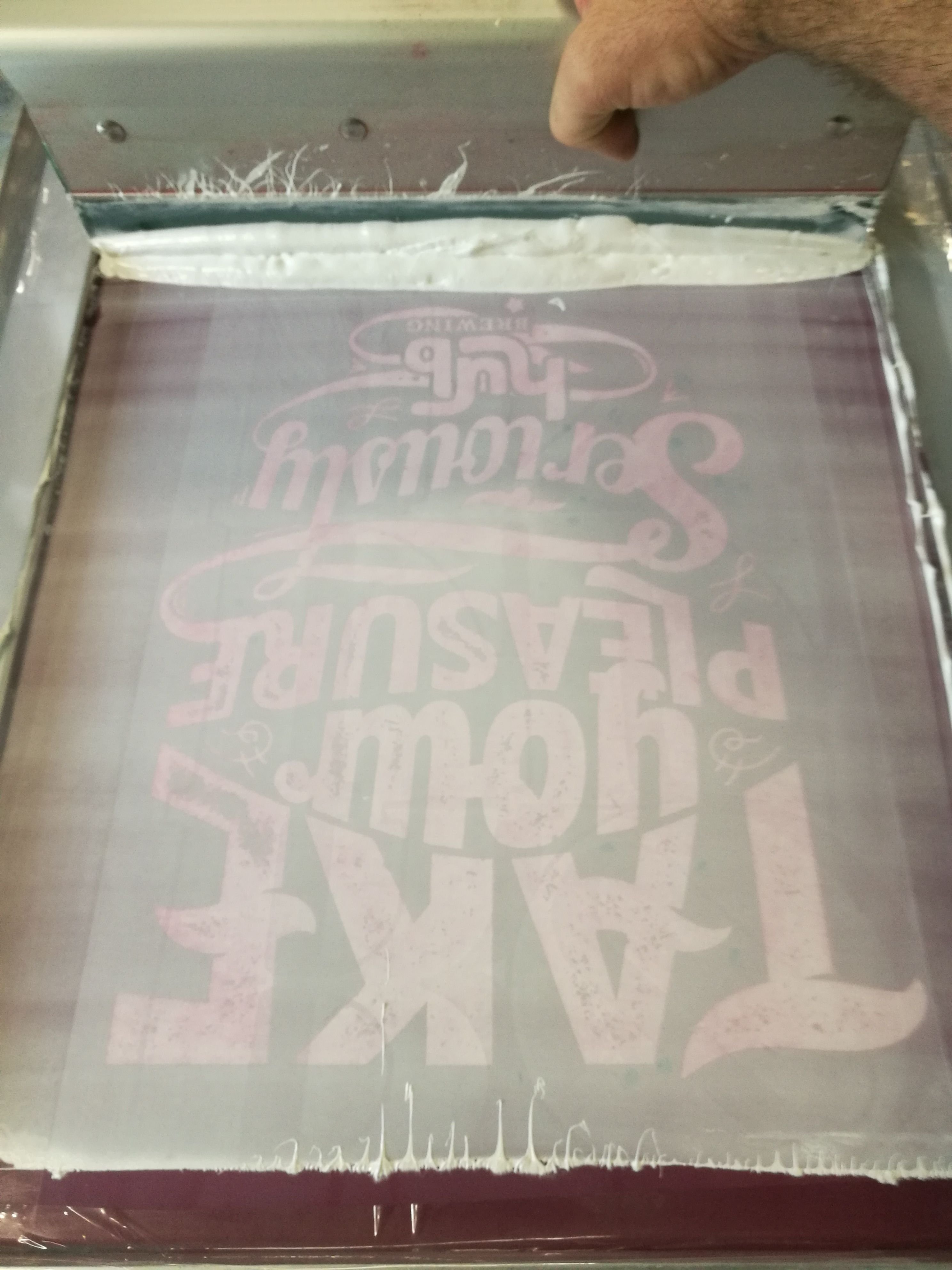

Once the screen has been exposed it's time to wash out the screen with water.

As you can see where the transparency was the emulsion stayed soft and easy to wash out of the screen.

Once you have washed out the screen let it dry in the sun.

Step 5

Blocking out the screen.

When shooting the screen you sometimes get little pin holes in the emulsion from dust etc.

So block them out with some screen filler.

Let it dry then you are ready to set up the screen for print.

Step 6

Setting up for print.

Load your screen onto the carousel, and tape up around the printing area.

Find your center point of the design to line up with the center of your printing platen.

This print is a simple 1 colour design, so just line it up and lock it in and we are good to go. With multi colour prints you have to register each colour and lock them in and is a lot more time consuming.

Put the ink down and you are ready to print.

Step 7

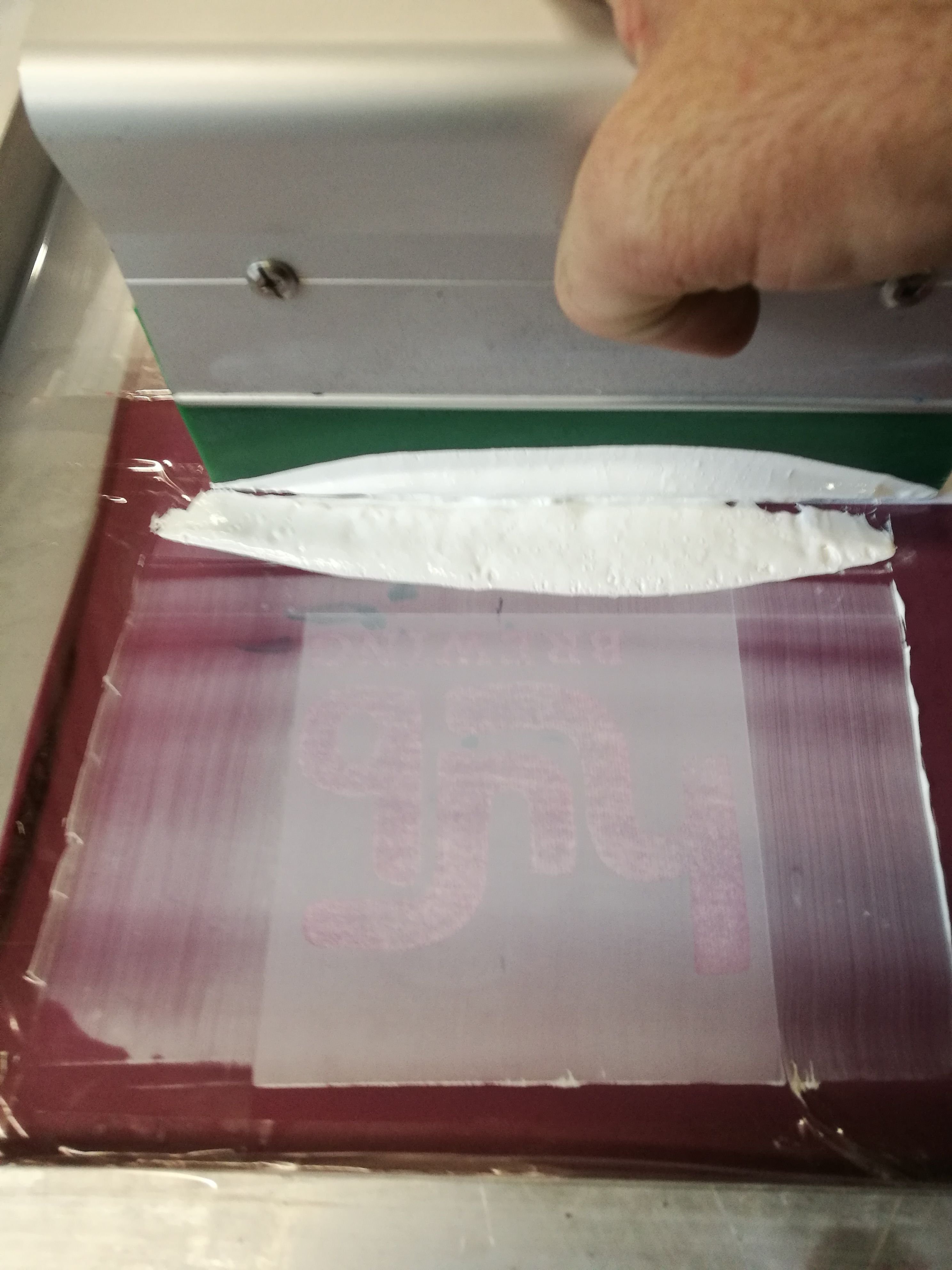

Printing

Load your shirt onto the platen and get the ink on your squeegee. Use medium down pressure on the edge of the squeegee blade and pull towards you.

Pull the ink through the screen twice then dry the ink with your flash or with a heat gun, then apply the 2nd coat with 1 coat of ink.

Now your shirt is printed. Touch dry the ink with your flash or heat gun and stack up the shirts.

This job has a back and front print. I just printed the back of all the shirts and now it's time to print the front.

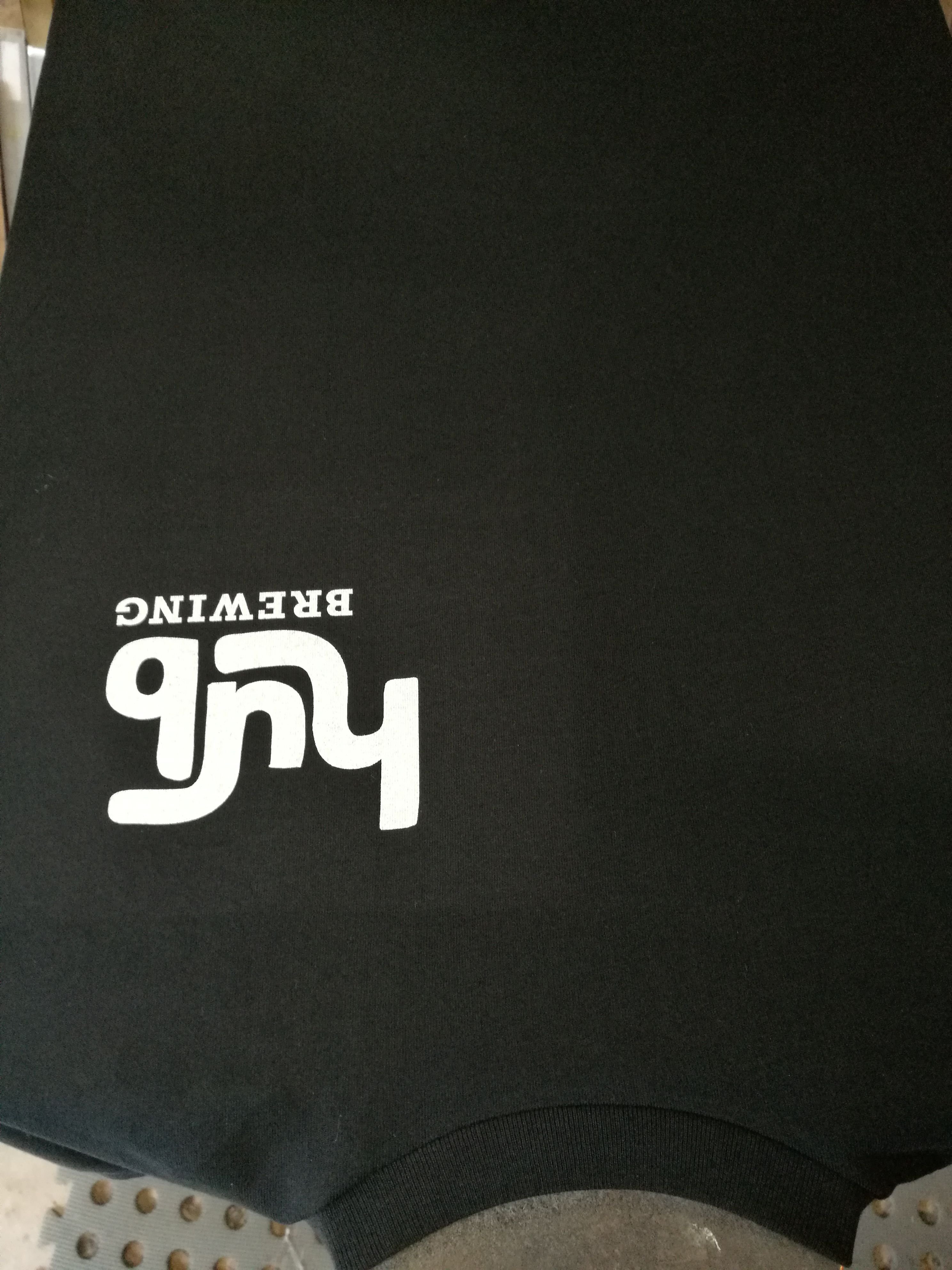

The front print is a pocket print. ( logo on the left side where a pocket would be)

Mark out your center line for the pocket print and same set up and printing technique

Step 8

Curing the ink.

Once all your shirts are printed it's onto the final stage of curing the ink. This is very important to get right so the ink bonds to the fabric and doesn't crack or wash off.

You can use a tunnel oven or a heat press for this.

I now use a heat press for smaller jobs.

Now you have your final product a 1 colour front print and a 1 colour back print.

Step 9

Deliver the shirts.

I took the shirts to the Hub Brewery and they loved them !!

Very happy customer's I even scored some free beers 👍

I hope you enjoyed my quick how to screenprint post.

If you have any questions regarding screen printing please leave a comment below.

And if you are in Australia and would like some shirts printed please send me a email to vcclothing@gmail.com

For a free quote.

Or contact me on my printing FB page

https://m.facebook.com/vcscreenprinting