Part 1: Skin

Part 2: Muscle

Rationale

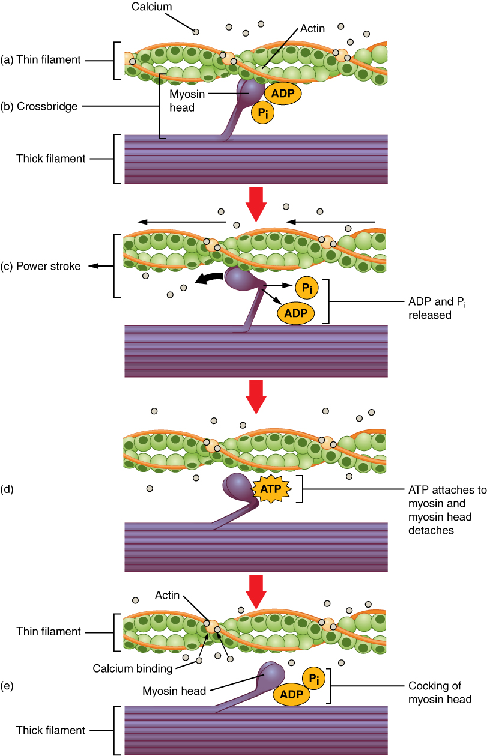

Muscles are filaments made out of proteins whose structure is dependent on energy to stay relaxed, its rate is a property called lusitropy. This is seen in the heart as active relaxation during diastole.

Elastic elements exchange heat with the environment when they stretch as their surface area increases. While stretched they lose heat faster. As seen in this example of a rubber band.

First stretched (hotter, redder)

Then contracted (colder, blacker).

source, great youtube channel

Biopolymers

In reality, muscles spend energy when they relax not when they contract. That's the reason they stay contracted during cramps or the reason for rigor mortis, until they can get the energy chain back on track.

Rubber as muscles contains biopolymers and it behaves similarly. Artificial muscles take the opposite approach as they require energy to contract.

Normally heat expands not contracts but materials like Zirconium Tungstate and thermoplastics (nylon), heat is an incentive for coil-like structures to contract in some materials as they expand in width while shrinking in length. 1

Shape memory materials and nanostructures offer similar properties but are expensive and not readily available as for instance, nylon that has this property.

Their current strength is approximately 5kW/kg, around 100 times what human muscles can do and more close to a rocket engine than to a human. Materials like nylon are currently being used to mimic the structure of muscles. They are readily available and are easy to print in 4D

They can be controlled by using a material that absorbs electrical energy and delivers heat, but the response would be slow and the muscles would be relatively big as nylon is not an electroactive polymer.

In the human body, this problem also happens, that's the reason the body uses different types of muscle fibers depending on mitochondrial activity and structure (Type I and Type II) some with high speed but low endurance (Red) and some with low speed but high endurance (white).

As with any other form of artificially powered structure weight power ratios are a limiting rate. Other approaches like McKibben muscles that use pneumatic actuators offer a better solution at the moment.2

For High-speed high precision movements, the best solution is hydraulic motors and brushless motors like the ones used for camera stabilization. Of course here assisted computational vision and processing are also needed.

EAPs

Electroactive polymers, change dimensionally secondary to electrical stimulation. Can be classified based on their response mechanism in electronic (ferroelectric (co)polymers, dielectric elastomers) and Ionic (carbon nanotubes, ionic polymer metal composites). They offer properties like expansion when exposed to an electric field.

The next generation of muscles, that actually do mimic the process of the rubber band approach, like human muscles, is that of thermoplastic dielectric elastomer gels 3, also known as a subtype of soft machines. The dynamic properties of self-assembly make it similar to soap, which produces spherical, cylindrical or planar structures. 4

Video - Soft Robots (Duration 1:33)

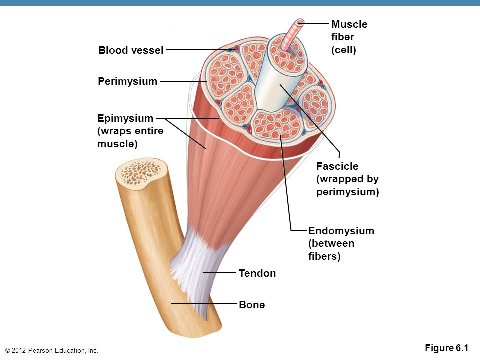

Just like in the body a combination of all the above-mentioned solution can be packed into different but synergic groups of muscle fibers like in a real muscle.

Muscles are as good as their attachment since the strain and force they elicit has a direct and opposite effect on the bone they are attached to. That's perhaps the more interesting part the exoskeleton in part 3

There you go. Almost ready to build that armor.