I thought I'd share some photos from my work as a guitar maker. All of these pictures were taken on my trusty old Galaxy S3,which was kindly given to me by someone who had just upgraded. Not the best camera, but I quite like the effect you get with the addition of a few built in filters.

I'm also making this post from the same phone, which, when you think about it - the level of technology we have reached, being so freely (or cheaply) available - it's quite amazing.

Sometimes when I'm working on a guitar and I look at what I'm doing and what I'm seeing, I feel so glad and grateful (not to be sat at a desk looking at a computer screen) that I just have to stop and take a photo...

All my guitars I build one at a time, using traditional methods and hand tools. I've never made two the same.

Most people don't know what the inside of a guitar looks like. The underside of the soundboard has these 'braces' which add strength to the spruce wood, which may be as little as 2mm thick. They also give definition to the tone.

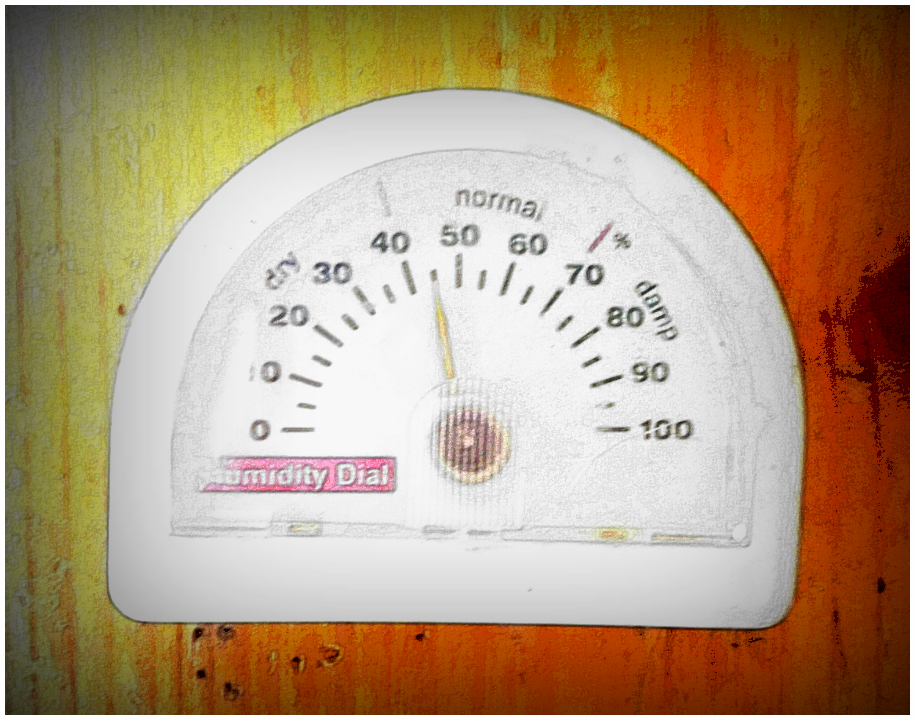

When working with thin, delicate wood, humidity is vitally important. I don't have a clock on the wall but I do have this hygrometer, which I keep a constant eye on.

These are the tools I use for thicknessing the soundboard. A sharp hand plane and this measuring device, accurate to 1/100th mm.

Finishing the body of a guitar before polishing. I use a cabinet scraper as much as possible instead of sandpaper. It is a more traditional method and creates less dust and a finer finish.

Planing a piece of ebony wood for the fretboard. It's such a hard wood, that it blunts all but the finest of steel in no time. It's so dense that it sinks in water, unlike most other wood which floats.

Me sitting outside my workshop. It's just a caravan really, but it's in a good spot and I don’t need much more than that. It's the biggest workshop I've ever had.

Here's the same guitar being polished. It's a long process that can take a month or more. Thin layers of natural shellac dissolved in alcohol are rubbed onto the wood using a cotton cloth. As the layers build up it develops into a deep, golden shine. This technique is called French polishing.

Carving the bridge.

Sweeping up wood shavings. I do that a lot. It's part of it.

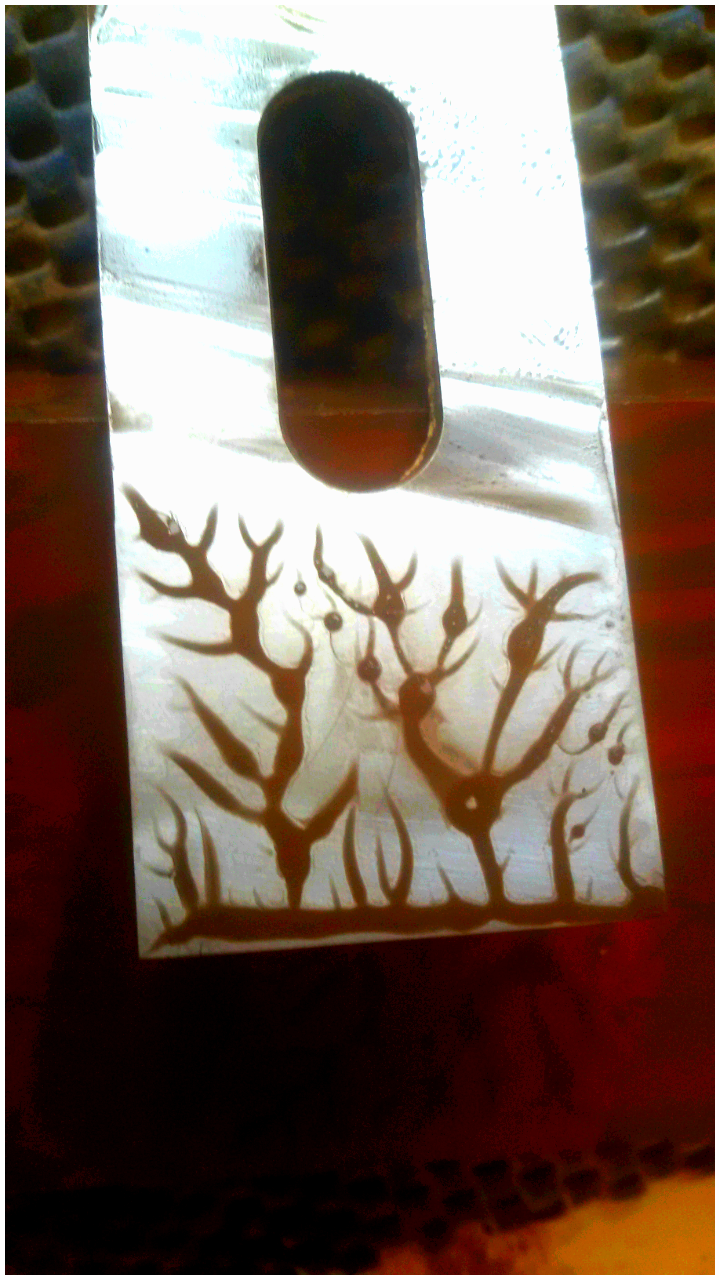

Sharpening a plane blade. To work best, the tools I use need to be razor sharp. That way it takes less effort to cut through the grain and leaves a cleaner finish.

I use a Japanese water stone for sharpening tools - as opposed to a western oil stone. When the back of the blade is flat, the water makes these lovely organic patterns on the steel.

This is the plane. (For tool nerds, it's a Lie Nielson smoothing plane based on the old Stanley Sheffield plane, except with a thicker blade which has been cryogenically frozen as part of the tempering process. Made in the USA)

Turning an endpin in the drill-press. I don't have a turning lathe, but this works well enough for little things.

One of my more unusual classical guitars.

I use all different woods and even shells from the sea of Galilee to make my soundhole rosettes.

The back ready to be glued on. A very significant moment as it closes the box - hopefully for many years.

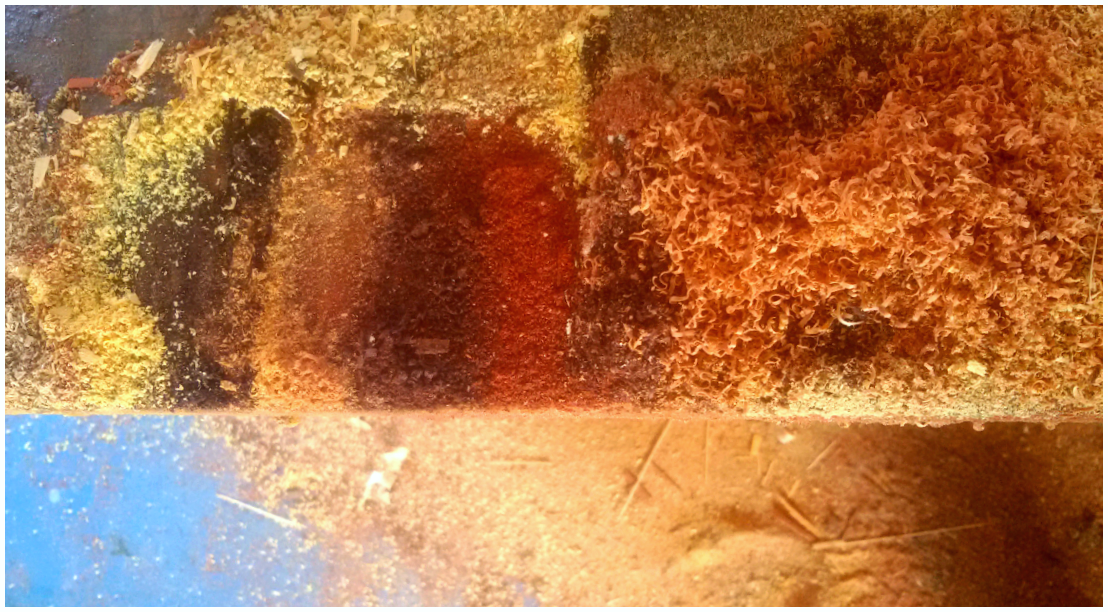

Various colours of sawdust from various types of wood - cut into thin strips for decoration and inlay.

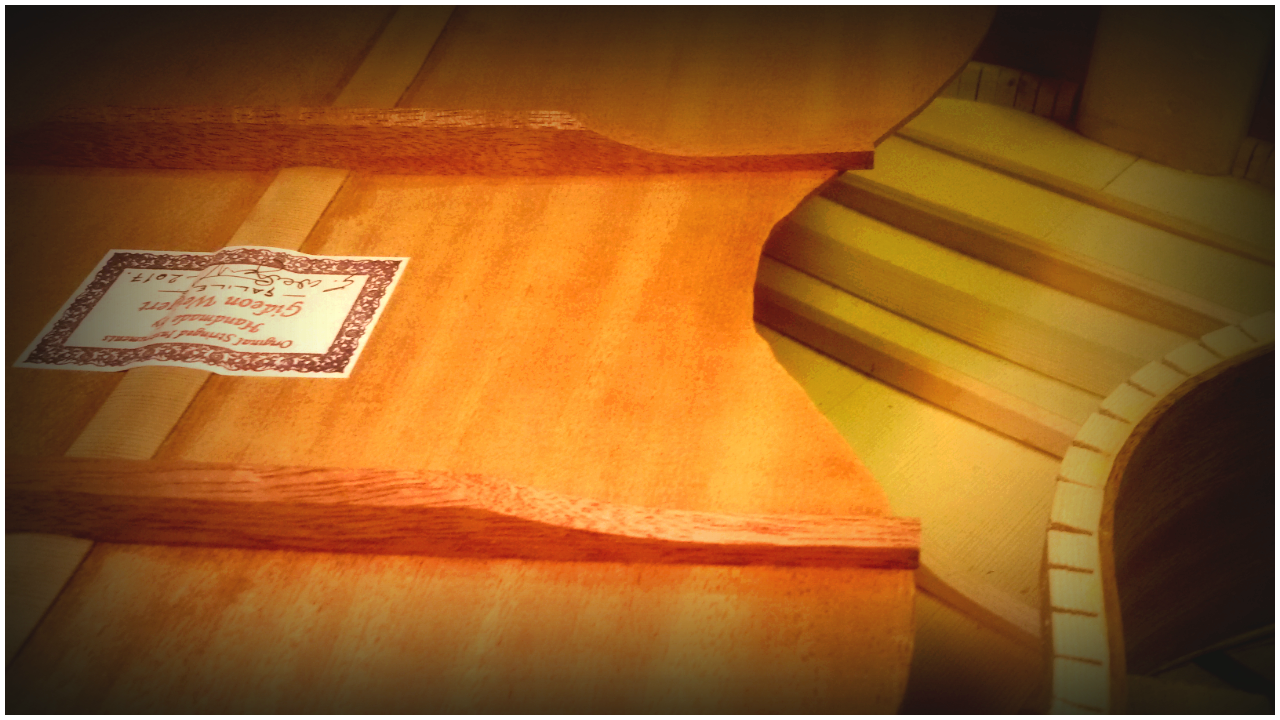

Preparing the label. Another significant moment. I sign my name and write the year and where the guitar was made - Galilee. It's a kind of historical document.

Dust to dust

It's the little details - like this square carved heel. I was also satisfied with the colour I achieved on the neck by using a stain made from walnut husks.

Sometimes I lose track of time and don't notice when the coffee boils over.

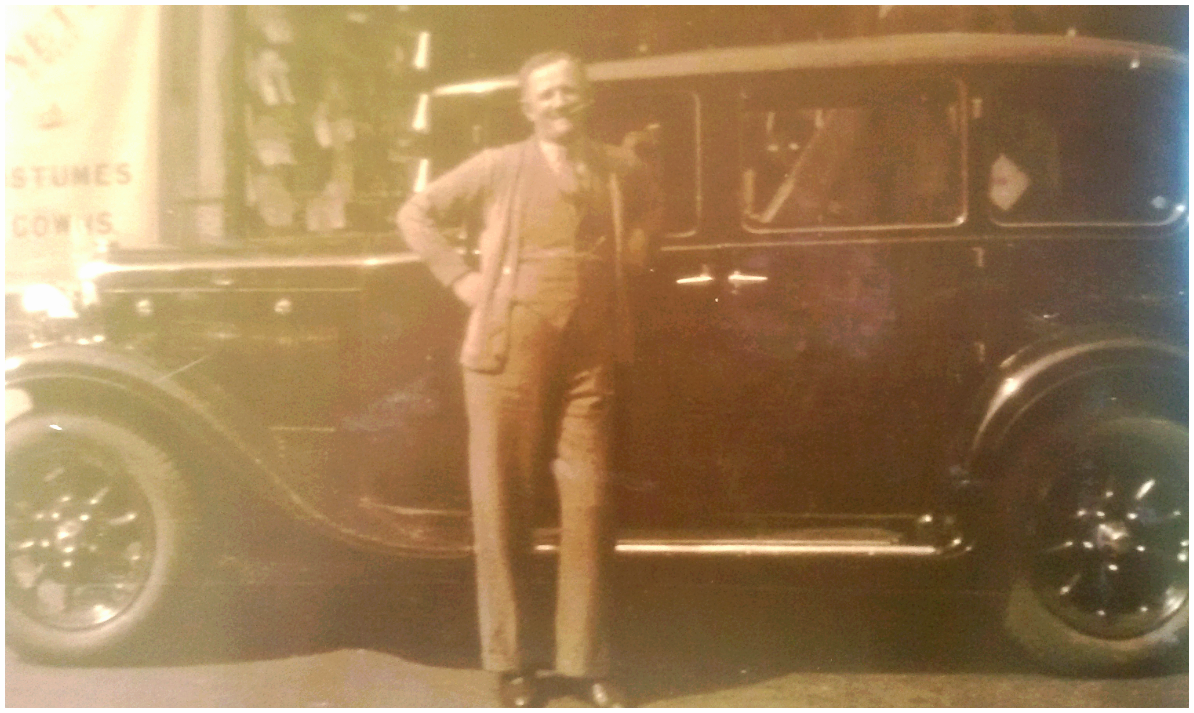

These tools belonged to my great grandfather. They still work, even after about a hundred years. Think about that.

This is him, next to a new car.

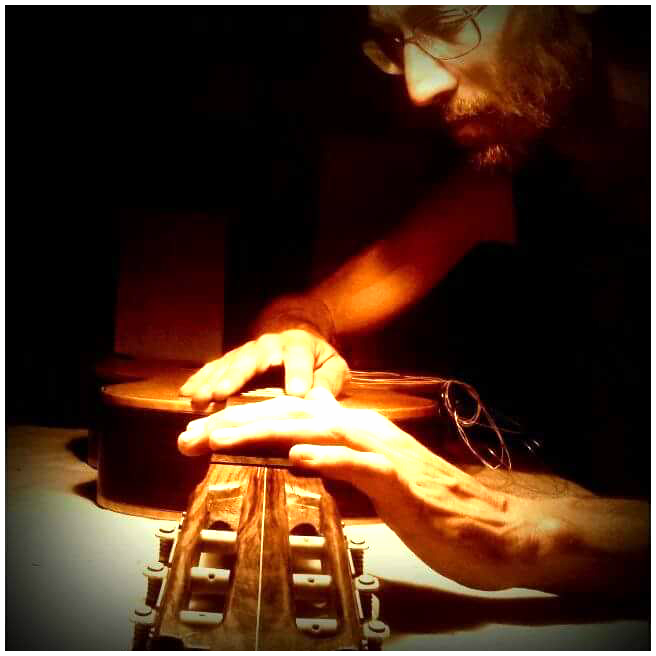

And this is me, with a new guitar

For more information about Gideon Weigert handmade guitar, visit www.handmade-guitars.com.