Hi steemians! In this post, i am sharing some of my reflections on the last 2 years of my life - the Phd and my research topic here. You can read my love-hate relationship with PhD Part 1 here which are some of my doubts on the value of PhD. In a way, those thoughts were in my mind and also were part of the reason why I eventually dropped the PhD. After I recently withdrew from the program officially, it was a mixture of relieved and heavyhearted feelings. On one hand, i wanted to preserve on something i really like and want to do. On the other hand, it was a decision between PhD and family - the husband had to move for a job, so the wife had to choose family (both husband and daughter) or PhD. I know of people who are able to do the long-distance thing. But i just can't stand the thought of being away from the husband. Denying my daughter's fatherly love also does not seem fair to both the husband and daughter either. As much as possible, I would prefer my daughter to grow healthily and well with her father's love.

So a piece of advice here:- if you are married in your 30s, with a young child and are considering to do a PhD, my advice is PLEASE THINK AT LEAST TWICE.

It will be a hard time.

But again, the decision is yours to make, just like my decision was mine to make 2 years ago.

A little background of myself

Unlike many computer scientists and mathematicians around in steemit, I am from a vastly different field. I graduated from my Bachelor’s degree in Materials Engineering in 2007, with a thesis topic in nuclear waste containment. My first job was a research engineer in a Singapore research institute specialized in Life Cycle Assessment (LCA), a kind of environmental impact assessment methodology. Later, I moved to Austria with husband and very fortunately found a relevant research job doing LCA studies on biofuels.

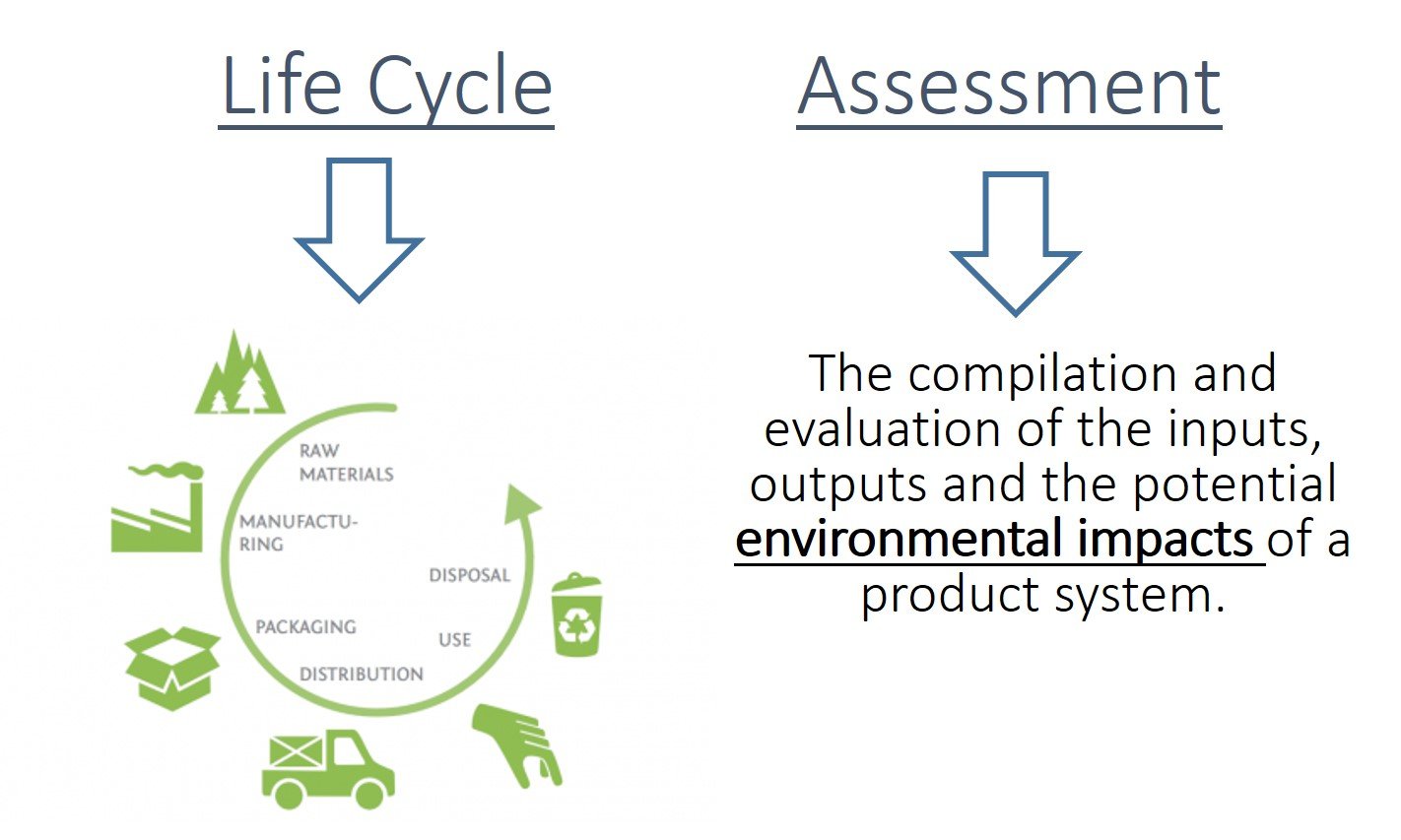

What is Life Cycle Assessment?

Breaking the 3 words down. Life cycle is basically the series of stages in making a product. For example, in making a plastic bottle, it will have to start with crude oil (raw material), the production of plastic resin and blow molding process, and then sold to maybe Coca Cola for instance. The Coca Cola guys packaged them and the bottle ends up in your hands. Then, depending on what kind of consumer you are and which country you are in, the plastic bottle can end up in different places - recycling centers, incineration centers, landfill sites or maybe in the ocean. As life cycle analysts, we map out the different scenarios and calculate the possible different environmental impacts such as global warming potential, acidification, etc etc.

Decided to have a formal education in sustainability and environmental management, I did my Masters in Environmental Management in Singapore in 2012.

What i learnt from the environmental management program

From my Master’s program, I learnt that in solving an environmental problem, people not only need just the environmental engineers to develop technology like waste water treatment, air emissions treatment, land/soil remediation, etc. We also need economists and policy makers to discuss the carrots and the sticks to adjust consumer behavior (e.g. carbon tax, carbon trading, etc). We also need government lawyers to write codes of practice, acts and regulations to prevent technology companies from polluting the environment, and also penalty by fine and jail if needed. We even need to think about the supply chain, the operations and the business models of companies. Changing the supply chain and business models can change the life cycle environmental impacts. For example, are distributed manufacturing models more environmentally friendly than centralized manufacturing models, since typically environmental impacts from transportation can be eliminated? Hence, to solve an environmental issue, knowledge is required from the mentioned wide range of topics. We need this multi-pronged approach in tackling the possible environmental impact of emerging technologies, such as nanotechnologies, 3DPrinting, etc. As a result of my learning from this program, I believe that many complex and difficult issues in fact require knowledge from a wide range of expertise.

This kind of notion leads me to convince me that it is better to be a jack of all trades.

After my masters, it was moving from university to university and working on different research projects for 2 years. Finally, I obtained a PhD scholarship to study in a Singapore university in Engineering Product Design, an interdisciplinary PhD program in 2014. That was the start of my student life all over again…

Interdisciplinary PhD means core in nothing

Increasingly, many PhD programs are interdisciplinary and there seem to be many claimed benefits. I was in such a program for the last 2 years. Some of the benefits include allowing the PhD student to choose relevant subjects that will greatly help in their PhD thesis. Giving PhD students the option to choose subjects that they like can help them in bringing ideas from different fields and connecting the dots in their thesis. My university was listening to advice on making their graduates more marketable, be it to universities or industry. But most importantly, it is to make sure that graduates from PhD program have skills and knowledge that can be transferred easily from job to job. I was pretty convinced by this because I understand that to be more marketable in the increasingly competitive and global market, I need core skills and also other soft skills that I can use wherever I go. Another reason was I have seen many personal friends who graduated with a PhD and in the end, not working in their field because the relevant jobs are too little. In my PhD, I took courses like statistics, design management, study of materials, thermodynamics of materials, courses which I think would help in writing my thesis. I have to admit that I gained a lot of knowledge during the last 2 years, which was a very different experience from working on research projects in research institutes and universities. My classmates used to joke about the fact that we study in wide ranging subjects means that we are really core in nothing. But, I think this may in fact be the right phd education model - Trample the boundaries.

Choosing 3Dprinting as the domain

It is a long story on how i ended up in the 3Dprinting domain. My original thesis or PhD project was on life cycle assessment of membranes in waste water treatment, working with two professors - a professor in developing membranes and another professor in life cycle assessment. On the first day of my PhD life, I drove to the university with huge aspirations. I was looking so forward to meet them and discussed about my research ideas which I had done in detail and documented in power point slides. Guess what? To the horrors of my horrors, – one of them, who was the domain expert in membrane announced that he is leaving the university. Now, tell this to another PhD student and they will freak out. It is one thing to leave the university. But it is another thing to recruit a PhD student three months ago, got her here and announced he is leaving the university. And then, the first one month of my PhD life was just busily looking for a new domain to apply LCA on. What an eventful first month. Talked to five professors. Interested in one. The next five months was busily reading up on this new domain that I was going to work on – 3Dprinting aka additive manufacturing.

What is 3DPrinting?

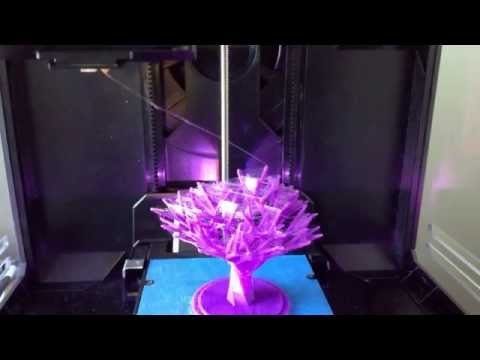

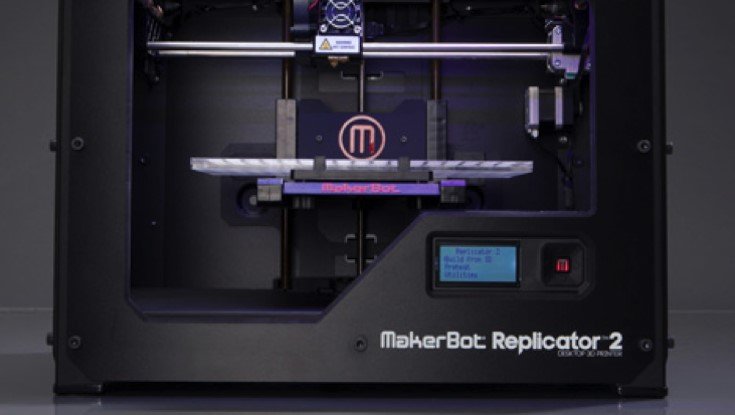

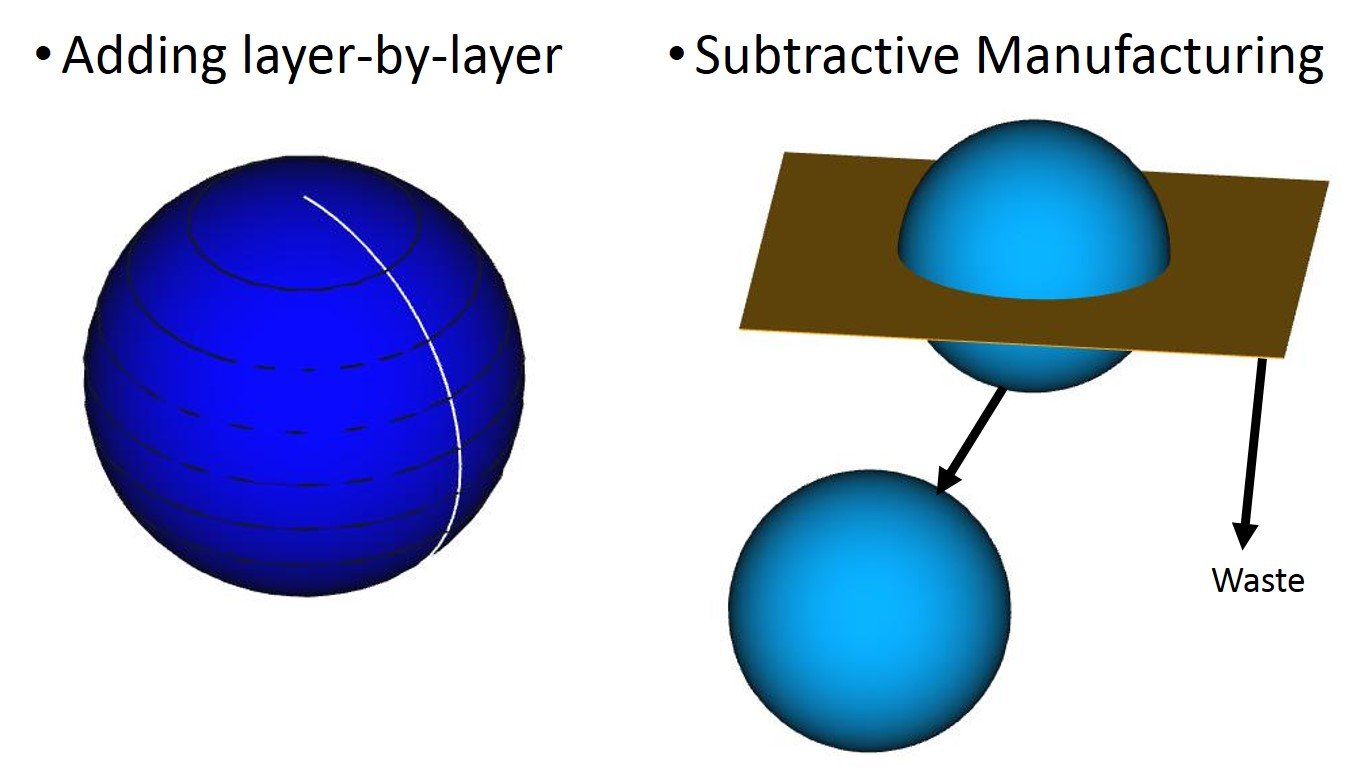

3Dprinting is an additive manufacturing process – adding layer by layer to form a product. Similar like paper printing in terms of ink, but ink is added on the moving platform in the x,y and z direction. The ink is usually melted material at the heated nozzle - usually heated to just above the melting point of the materials. There are many different 3DPrinting technology and many different materials (Plastics, metal,ceramic) in different forms (powder, filament). The most popular 3DPrinting process is the Fused Deposition Modeling (FDM) which is also common in domestic 3dprinters. A very common material to print use in FDM printers is either bioplasic called Polylactide (PLA) or a petroleum-based plastic, Acrylonitrile butadiene styrene (ABS). You can click here to know more about 3DPrinting. Have a look at the makerbot replicator in action below!

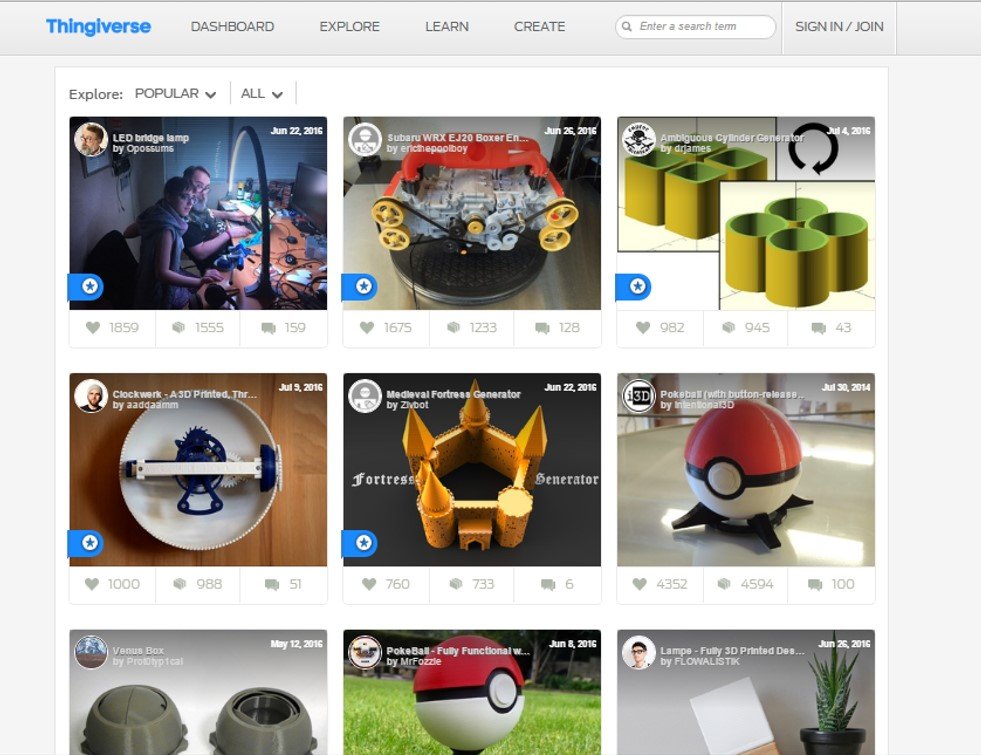

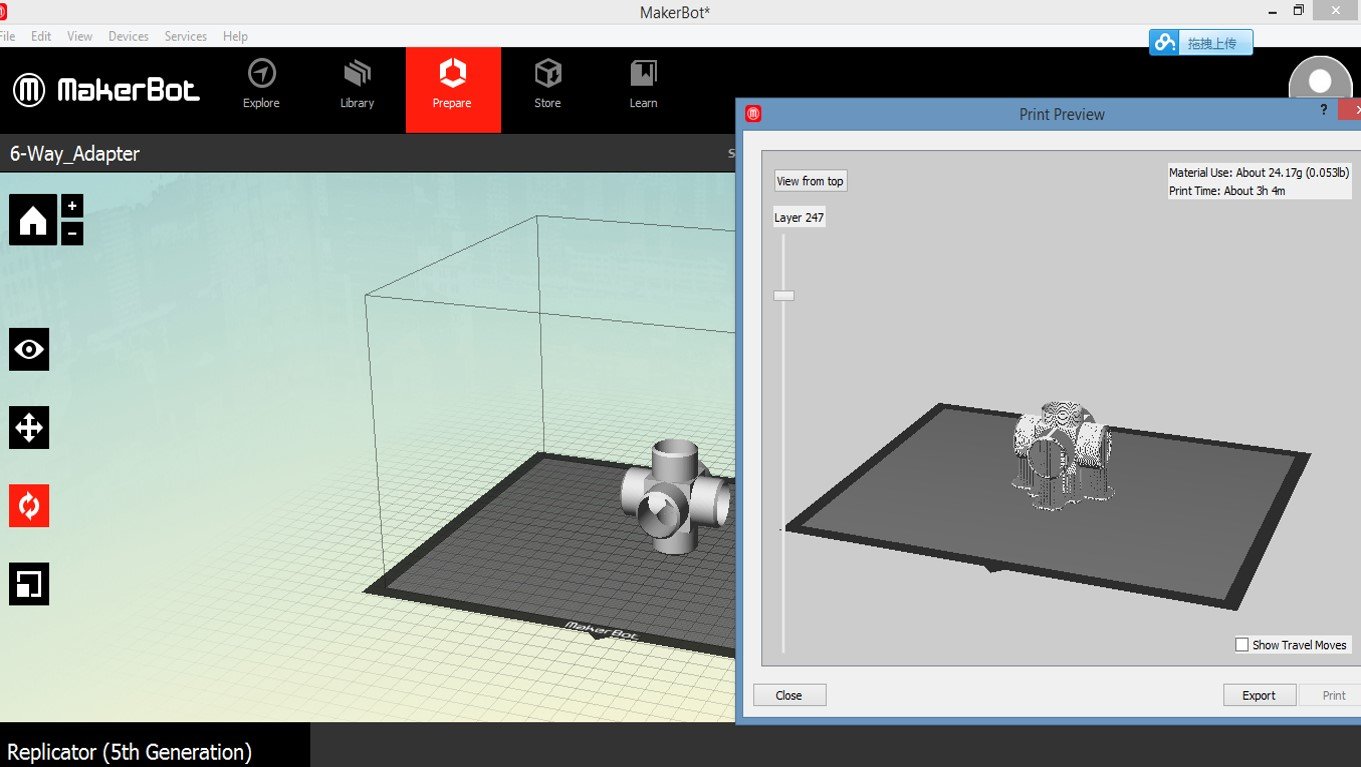

A huge portion of my life became occupied with reading papers, going for classes and browsing on thingiverse.com. Downloading STL files and testing them out using makerbot desktop software.

Uploading them to makerbot software, checking out the materials consumption and documenting the numbers.

Testing out the prints on the Makerbot Replicator

Many have in fact raved about how environmentally-friendly 3D printing is. And so as graduate students, we are supposed to ask critical questions and identify research gaps. So, here it goes...

My research questions in 3Dprinting

3Dprinting is a technology that is often used to manufacture highly customized and complex part shapes. One advantage of 3D printing over traditional subtractive manufacturing method is the elimination of molds. Below is a very simplistic example of how subtractive manufacturing generates more waste than additive.

There is this popular notion that "Complexity is free" in 3dprinting because no extra support materials is required for printing, and thus can save cost . I would like to challenge this notion of “Complexity is free” in #3Dprinting from the environmental perspective. Is it really “free” in terms of resource consumption and waste generation? Do shapes in varying complexity give a different environmental profile? I will be using Life Cycle Assessment and Design Thinking as the methodologies.

Stay tuned as I post more about my independent research!

Follow me @coinbitgold independent research project!