"Ceramic Materials and its Advance Application to Aerospace Industry"

Usually when one heard of the word “ceramic”, one would eventually refer it to pottery. Most people only possessed information on traditional ceramic method, application and products such as bricks, tiles, earthenware, plates, porcelain, toilet bowls, etc. Even if we google the word “ceramic”, most popular results include pottery, ceramic arts and other traditional ceramic products. Ceramic materials are inorganic and non-metallic materials, mostly fired at higher temperature to form a solid body or to come up with a partly crystallized product. Various methods such as dry pressing, extrusion or wet processing, slip casting, etc. are also being practiced. The most common traditional ceramic raw materials being used are clay minerals.

Generally, these clay minerals are mixed with sand as filler and water to obtain plasticity to be able to form initial ceramic products. These products are subsequently pre-heated then fired at higher temperature between 600 to 900 degrees Celsius to form traditional ceramic products such as stoneware and earthenware. This is the most common interpretation of the people when they heard the word ceramics. But ceramics is more than that and as far as we knew, ceramic materials have been long used in advance ceramic application.

According to Wikipedia,

The word "ceramic" comes from the Greek word κεραμικός (keramikos), "of pottery" or "for pottery", from κέραμος (keramos), "potter's clay, tile, pottery". The earliest known mention of the root "ceram-" is the Mycenaean Greek ke-ra-me-we, "workers of ceramics", written in Linear B syllabic script. The word "ceramic" may be used as an adjective to describe a material, product or process, or it may be used as a noun, either singular, or, more commonly, as the plural noun "ceramics".

Read more about ceramics here

Since my thesis involved calcined diatomite which was used as an additive to local commercial paint to primarily reduce the heat entry to household (which mainly comes from sunlight), I will give you an overview about why ceramic materials are used in aerospace crafts.

Ceramic materials have numerous properties such as high thermal resistance and high thermal shock resistance, low thermal and electrical conductivity, high hardness and high compressive strength, high modulus of elasticity, chemical resistance, superconductivity at absolute zero temperature and many more!

Ceramic materials are mainly known for its high melting temperature which means it can withstand high temperature. Ceramic materials are used as thermal insulators and refractories in aerospace crafts and space shuttles not just because of its high thermal resistance but also because of its lightweight properties. This low mass characteristic of ceramic materials makes it an ideal material for space shuttles and in aerospace industry. Lightweight ceramic materials are also used in military armors and weapons but we’ll focus on aerospace shuttles.

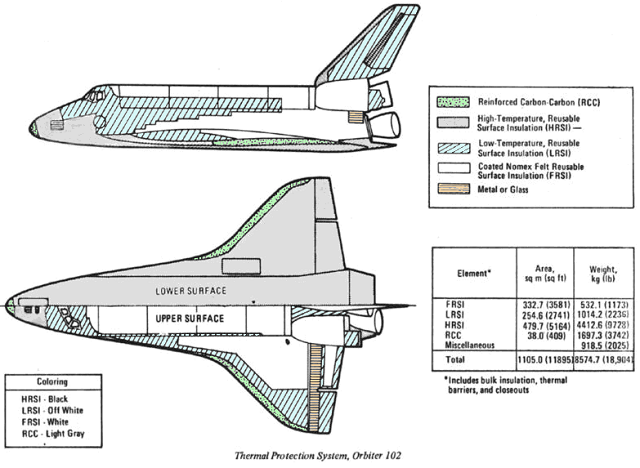

Advance ceramic applications in aerospace industry have already existed in so many years. Ceramic materials have been primarily used as external thermal protection and thermal insulators to space shuttles’ body, engines, exhausts and any other space craft components.

Ceramic fibers are used as heat shields for fire protection and thermal insulation in aircraft and space shuttles because they resist heat, are lightweight and do not corrode. Other significant characteristics include high melting temperatures, resiliency, tensile strength and chemical inertness.

So mainly, high thermal resistant ceramic materials are used to protect areas of space shuttles which experienced high temperature during launch and re-entry from space. Thus the lightweight property of ceramic materials made it suitable to primarily reduce the weight of the space shuttle.

A non-oxide ceramic called silicon nitride has excellent high temperature strength, excellent fracture toughness, high hardness and unique tribological properties. Silicon nitride aerospace applications result in superior mechanical reliability and wear resistance allowing components to be used under minimal lubrication without wear. These include jet engine igniters, bearings, bushings, and other wear components.

The strength and durability of each materials used are also key factors to be considered since the space shuttle experience different thermal condition during and after launch and re-entry which might affect the condition of the shuttle. This was of course because of the numerous accidents which happened in the past such as the Columbia disaster. Ceramics and materials engineers today have continually developed advance thermal insulators for space shuttles to come up with materials which exhibit excellent mechanical durability and reliability.

The properties and characteristics mentioned above are bit technical and somehow complicated. However, one does not need to have masters or doctorate degree to better understand advance ceramic application. So basically, ceramic materials are used as thermal protection for the space shuttle against high temperature during launch and re-entry and against cold temperature in space. The lightweight property of ceramic materials is due to its porous micro-structure, which I will discuss later in my blog.

References:

https://en.wikipedia.org/wiki/Ceramic

http://ceramics.org/learn-about-ceramics/ceramic-engineering-in-aerospace

https://www.azom.com/article.aspx?ArticleID=11443