"Lightweight Ceramics and its Application in Military Armors"

Military weapons and armors have been long used by humans since ancient and medieval wars. Continuous modernizations of these weapons and armors have also been progressing even today; from animal’s skins, to woods and stones, to metals and to synthetic materials. This history of improving protective covers has continued to threaten and surprise people of different states and nations. The latest, the strongest and the most advance materials which are being used in military armors and weapons today are known as ceramics.

Before, during medieval times, different types of metals and alloys such as copper and brass are being used in crafting armors. These protective coverings are used to prevent damage inflicted by infantry and artillery weapons usually during combat and/or ambush. Although these armors are durable and effective, its heavyweight characteristics are being disadvantageous to its user. Melee weapons such as the sword are also made out of metals such as copper, bronze and steel. Today, these medieval weapons are still being produced and used in self-defense etc. but not in modern warfare.

Today, everything has changed, numbers indirectly win conflicts; weapons do. These weapons and armors used in warfare have already evolved into extraordinary advancements which are being so effective against modern threats and war such as territory conflicts and terrorism. Current fighters today have been using high caliber guns which could inflict serious damage due to bullet’s high speed travel with enormous amount of kinetic energy. Thus armors both for individual personnel and vehicles have been developed and have been using specific materials to primarily counter and stop these types of weapons.

Studies and engagements in development of lightweight protective materials both for military personnel and military vehicles are widespread today. Lightweight armors are advantageous for military soldiers to maximize their actions, to become more flexible and efficient inside the battlefield while carrying full battle load. Ceramic materials are appropriate for these protective armors due to its strong, durable and lightweight properties.

The used of these materials have instigated after World War II as a response to development of high-powered weapons, advances in atomic energy, developments in electronics and communication and innovations of space travels. And from this period, ceramics materials have been protecting soldiers and military aircrafts and vehicles against modern weapons such as handguns, machineguns, and rocket propelled grenades (RPGs) and improvised explosive devices (IEDs).

Kevlar which is made out of fibers was an early enhanced armor for soldiers designed to stop and catch bullets. It is an excellent antiballistic material as huge amount of energy should be exerted to damage this type of protective suite. However, Kevlar has also its limit. In order for Kevlar to be effective against small handgun bullets such as 9 mm bullet weighing 8.0 grams fired at 373 m/s, 16 layers of Kevlar is needed. Therefore, the thicker the layers of Kevlar the more effective it is against bullets. Thus thicker layers of Kevlar are necessary to protect soldiers in battlefield than protecting policemen.

Ceramics are known to be one of the hardest materials. Unlike Kevlar which is primarily designed to catch bullets, ceramic armors break bullets. Unique properties and characteristics of high technology ceramics such as lightweight and hardness made ceramics the groundwork of modern military armor and the most important ceramic materials used for ballistic protection today are Aluminum Oxide or Alumina and Silicon Carbide. While one of the lightest yet the strongest ceramics material which is mainly used in tanks’ armor is known as Boron Carbide.

Owing to its excellent price-efficiency ratio, alumina is the preeminent ceramic armor material for vehicular applications. Only when an extremely low weight is required (e.g. for personal protection or for helicopters) silicon carbide materials may be used.

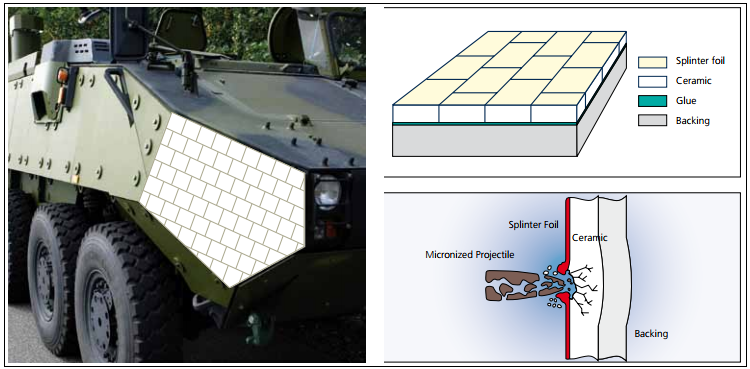

Ceramic armors such as trauma plates made out of boron carbides are designed to absorb and disrupt the kinetic energy of the bullet and reduced its impact. It is usually used as composite in ballistic vests and is durable enough to prevent bullet from penetrating the armor. Mainly, the structure of the lightweight composite armor is fundamentally based on four components; spall foil, ceramic, composite substrate and adhesive.

In a composite armor system, the ceramic is normally placed on the strike face, preferably perpendicular to the expected threat. Polymer fibers composed of polyaramide, polyethylene or polypropylene form the composite backing. The stiffening and structural enhancement of the individual polymer layers is achieved by impregnation and subsequent curing of the adhesive. Proper selection of adhesives, such as rubber, polyurethane or epoxies, results in the desired shore hardness, and thereby the required mechanical properties which can be tailored to the threat requirements.

Generally, the effectiveness of the entire composite system is centered primarily on the chemical bond of ceramic and composite substrate. Ceramic materials are known for its high compressive strength which then reduces the velocity of the bullet. The reduced speed of this bullet is completely absorbed by the elastic deformation in the composite substrate. For this purpose, spall protection is intentionally placed in front of the ceramic material.

The problem with this innovation is that ceramic material could not be able to sustain consecutive impacts and the material gradually loses its durability. But, engineers have somehow eliminated this problem by reducing the size of the ceramic tiles to its possible smallest structure; through this the impact will be distributed to every tile.

References:

http://ceramics.org/learn-about-ceramics/ceramics-the-military

https://www.ceramtec.com/files/et_armor_systems.pdf

https://www.azom.com/article.aspx?ArticleID=8092