A month ago I posted about bacteria producing plastics and thanks to @coinbitgold, who reviewed it in her #academiaspotlight series, it was read for more people. Today I want to tell you about other material that may be used to replace current plastics which excites me because makes me feel that the solution for plastics pollution is closer. First, let me ask you a question:

Do you think of trash when you eat one of these?:

What about packed fruits?

Well, what’s the problem with those?

Food packaging is a necessary process in food industry. However, there’s a lot to improve due to the biodegradable incapacity of the packaging used massively nowadays, which cause extremely negative impact on environment. Issues like the Great Pacific Garbage Patch (that's horrible enough to deserve a slap on our face) or endocrine disruption are consequences of non biodegradable plastics used and food packaging has an important role in this.

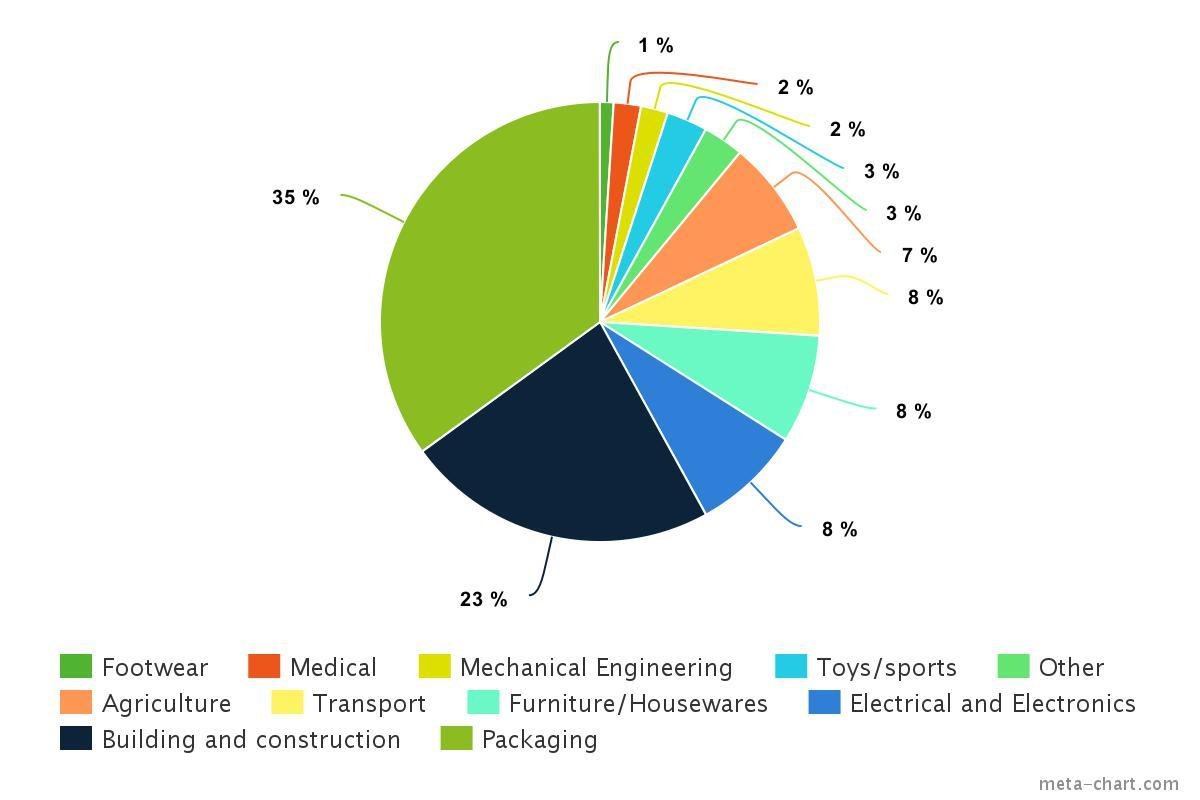

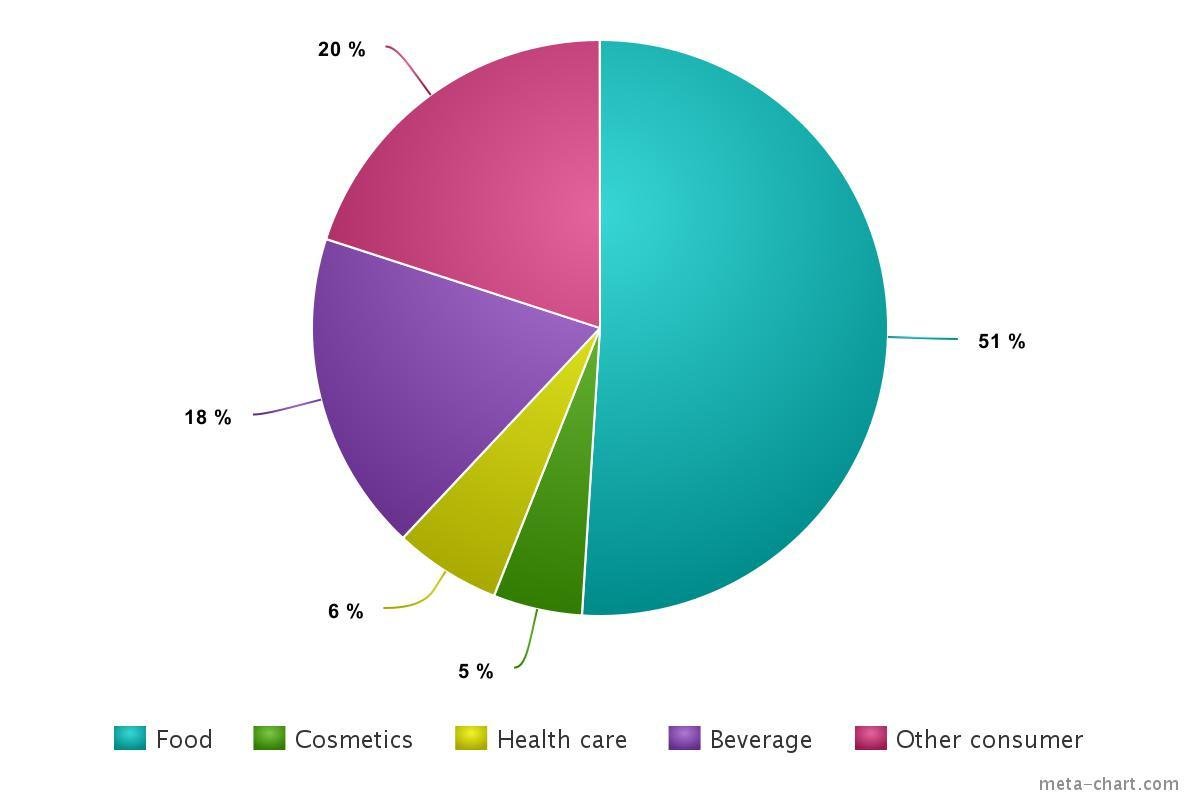

As you can see in charts below, 35% of all plastics is used in packaging and almost a half of that percentage is used in food packaging. It means that 18% of all plastics is used in food packaging, which leads to a huge responsibility for develop new materials that keep food fresh but also support the environmental conservation.

Plastics used in different fields

Global packaging by end market

And no, food packaging not only contaminate the environment. One of the concerns about non biodegradable plastics is that they aren’t biocompatible, which means that if it gets into our body it becomes a toxine harmful for our health.

How food is contaminated by its package material?

When food is packaged there’s a possibility of migration of substances from the packaging into food. Since packages have plasticisers and other aditives needed for adecuated mechanical and conservative properties, these and the package material itself represent then a direct source of contamination for food.

This becomes in other of the long list of reasons why it is extremely urgent to research and develop new materials that allow food transportation and commercialization without harming neither the environment nor ourselves.

A way out: Alginate and it’s promising properties

In the last years, alginates have become one of the most studied materials to develop plastic films. Alginates are the most abundant polysaccharides (“sugar” polymers) in brown seaweed or Phaeophyceae (image above) and are used commonly as gel-producing agent in food technology due to its safety. It is used in manufacturing of ice cream, sauce, syrup, pie filling, yogur, and others.

Besides, the plastic industry can also be benefited from alginates. Additionally to gel producing, this compound has other unique properties including thickening, stabilizing, suspending, film forming and emulsion stabilizing.

Industrial application as plastic films

Alginates have several advantages over current plastic:

- They are eatable due to their biocompatibility

- Their source is renewable

- They have cero environmental impact due to their biodegradability

- They aren’t expensive materials

However, two of the obstacles to apply alginates in films manufacturing are its permeability to water vapor and its solubility in water.

Usually, when the aim is to enhance a polymer property to its industrial application, another property is affected and the effort has to be directed to find the right combination of plasticizers in order to get the necessary properties. Nowadays, the research is following this purpose, leading the green industry to a major spread.

Bibliography

Article 1, Article 2, Article 3