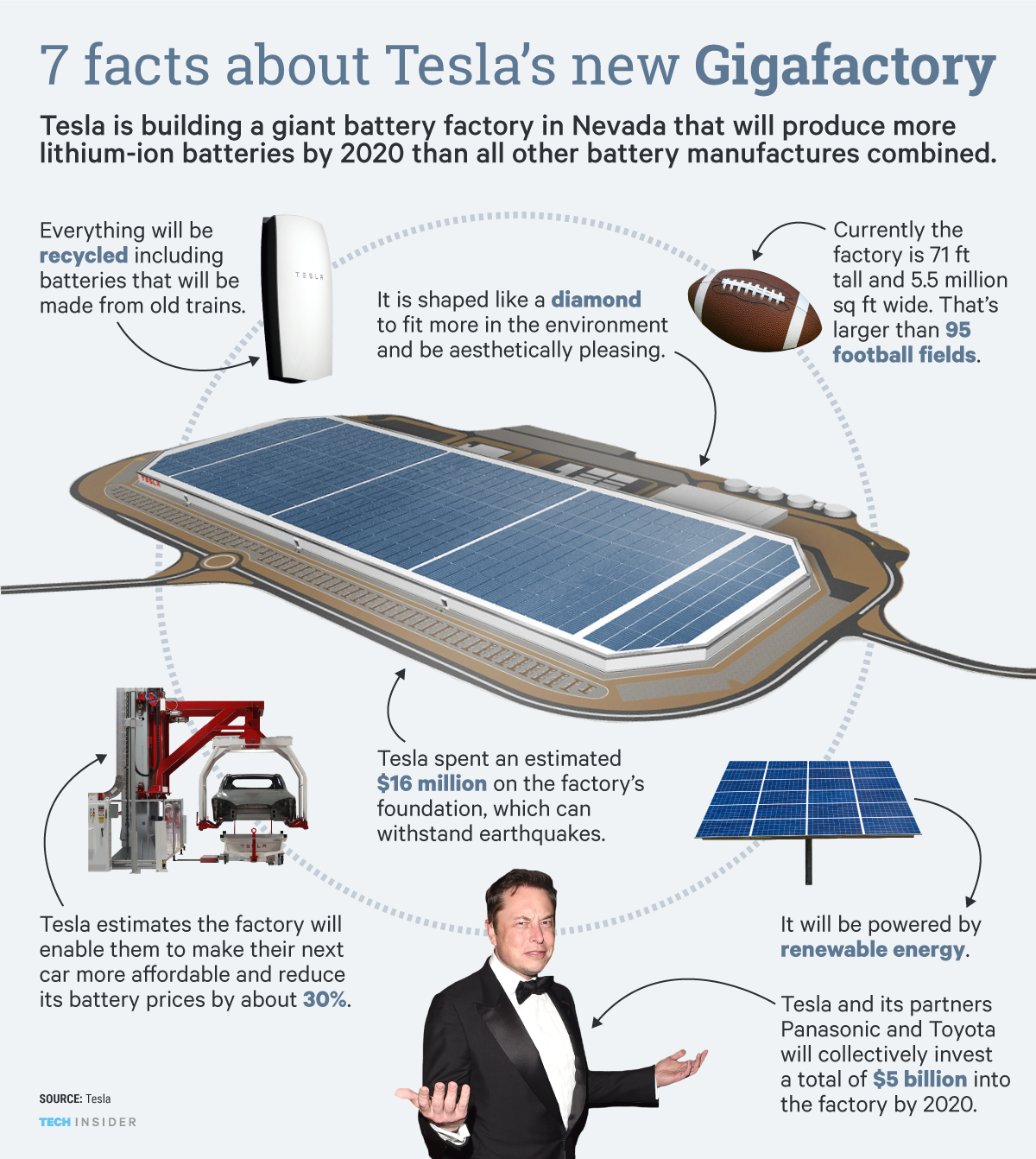

The Gigafactory is an extremely large factory located in Nevada, created by the company Tesla and Panasonic.

Its goal is to produce large quantities of Lithium-Ion Batteries which can then be used in Tesla's electronic cars, as well as their powerwalls (mountable batteries that can store energy).

Yesterday, on January 4 2017, the mass-production of battery cells has officially started!

The Gigafactory is a very ambitious project, and nothing like this was ever created before - by 2018, it will produce 35 GW/year in lithium-ion battery cells -

which is almost as much as the entire battery production of the rest of the world!

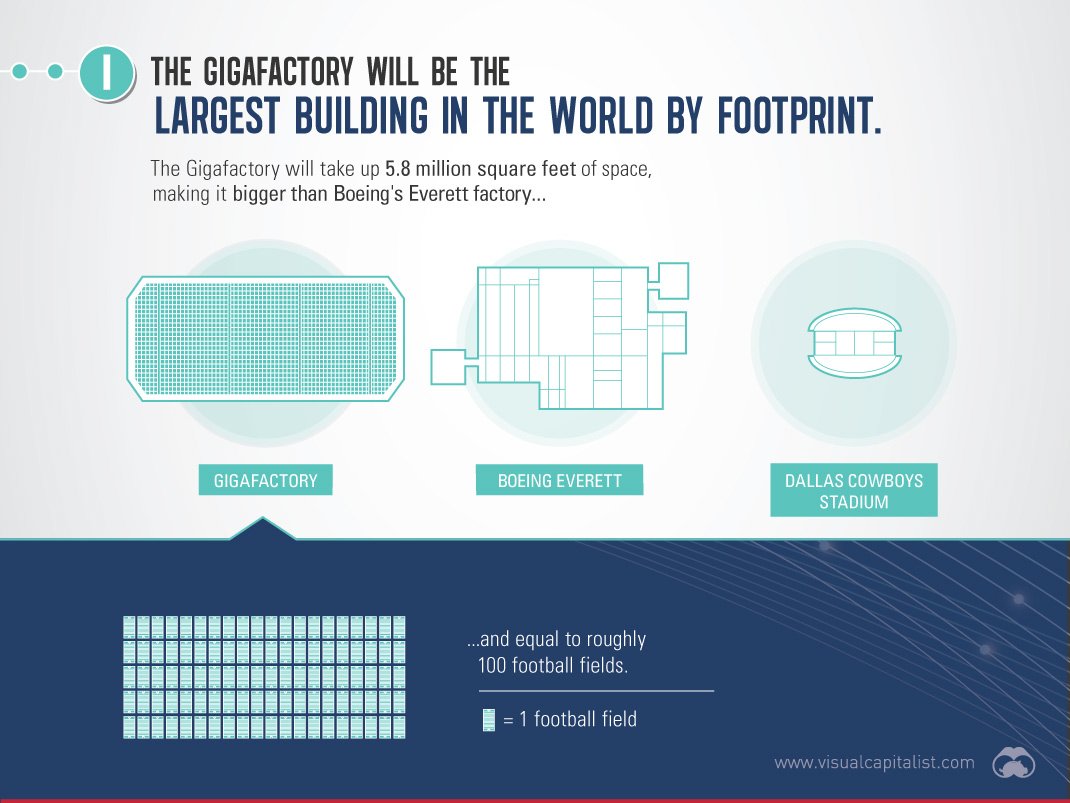

The Gigafactory will be the largest factory in the world with dimensions of 2-4 square kilometers (500-1000 acres) and over 6500 Jobs.

And the factory still isn't even complete yet - it's being built in phases, so that production can already start in finished areas while other parts of the factory are still being constructed.

Currently, the project is about 30% and already offers an operational space of almost 5 million square feet over 7 different floors.

The factory itself had been opened last year, but the construction wasn't even finished and the production still focused on assembling older products and preparing for the new production.

But from now on, the Gigafactory will actually start producing cells for the Powerwall 2 and powerpack 2 - and in the 2nd quarter of 2017, they will start producing batteries for Tesla's newest car, the Model 3.

This video shows the speed of the Gigafactory's construction:

Solar panels will be added to the complex later, making sure that a large portion of the energy supply comes from renewable sources.

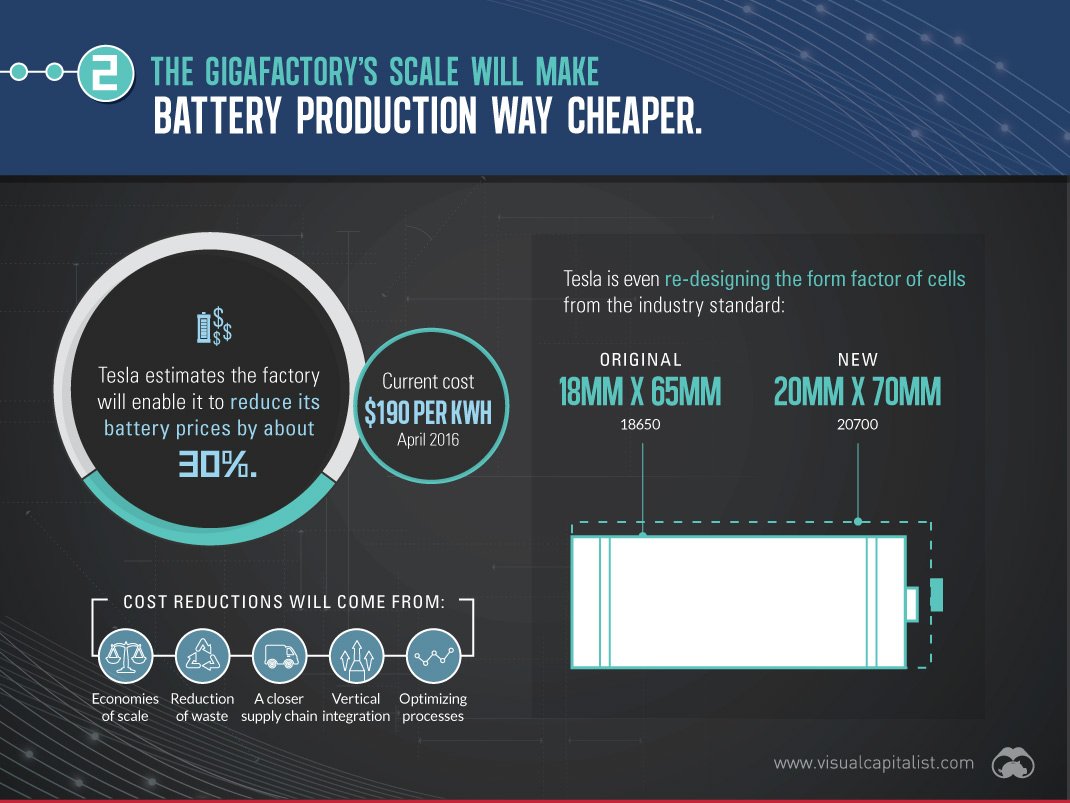

With something as big as the Gigafactory, Tesla doesn't only want to produce their own products, but also lower the general price for batteries, to make their products more accessible to a broader audience.

"With the Gigafactory online and ramping up production, our cost of battery cells will significantly decline due to increasing automation and process design to enhance yield, lowered capital investment per Wh of production, the simple optimization of locating most manufacturing processes under one roof, and economies of scale. By bringing down the cost of batteries, we can make our products available to more and more people, allowing us to make the biggest possible impact on transitioning the world to sustainable energy."

Images: 1, 2, 3, 4, Sources: 1, 2, 3, 4, 5

- Instagram -

© Sirwinchester