Its being a while I wrote about electrical system and most of my followers keep asking why.

Here i come another question or another challenge for electricians in the field of electrical system maintenance. You need to start your day with trouble finding. During your trouble finding what do you look out for will be discussed shortly via this article.

Effective maintenance program is the call to action if trouble finding is going to be effective within an organization, factories or at home as an electrician.

Below are the list of likely trouble you can find if periodic internal inspections are duly observed.

- Trouble 1: Rodents Gnawing in A Panel

When seeking for trouble during inspection its takes periodic checks internally that catch the condition stated above.

If the condition not cater for the panel enclosure can be damage from rodents gnawing or even shorting the terminal from nesting materials. During the inspection, the electricians need to clean up the invaded enclosure and look out for the place where the rodent access the panel. All open access should be seal off to prevent a recurrence.

NB.: There is possibility one missing knockout closure may be that is needed to all rodents to access the internal electrical panels.

- Trouble 2: Improper Installation

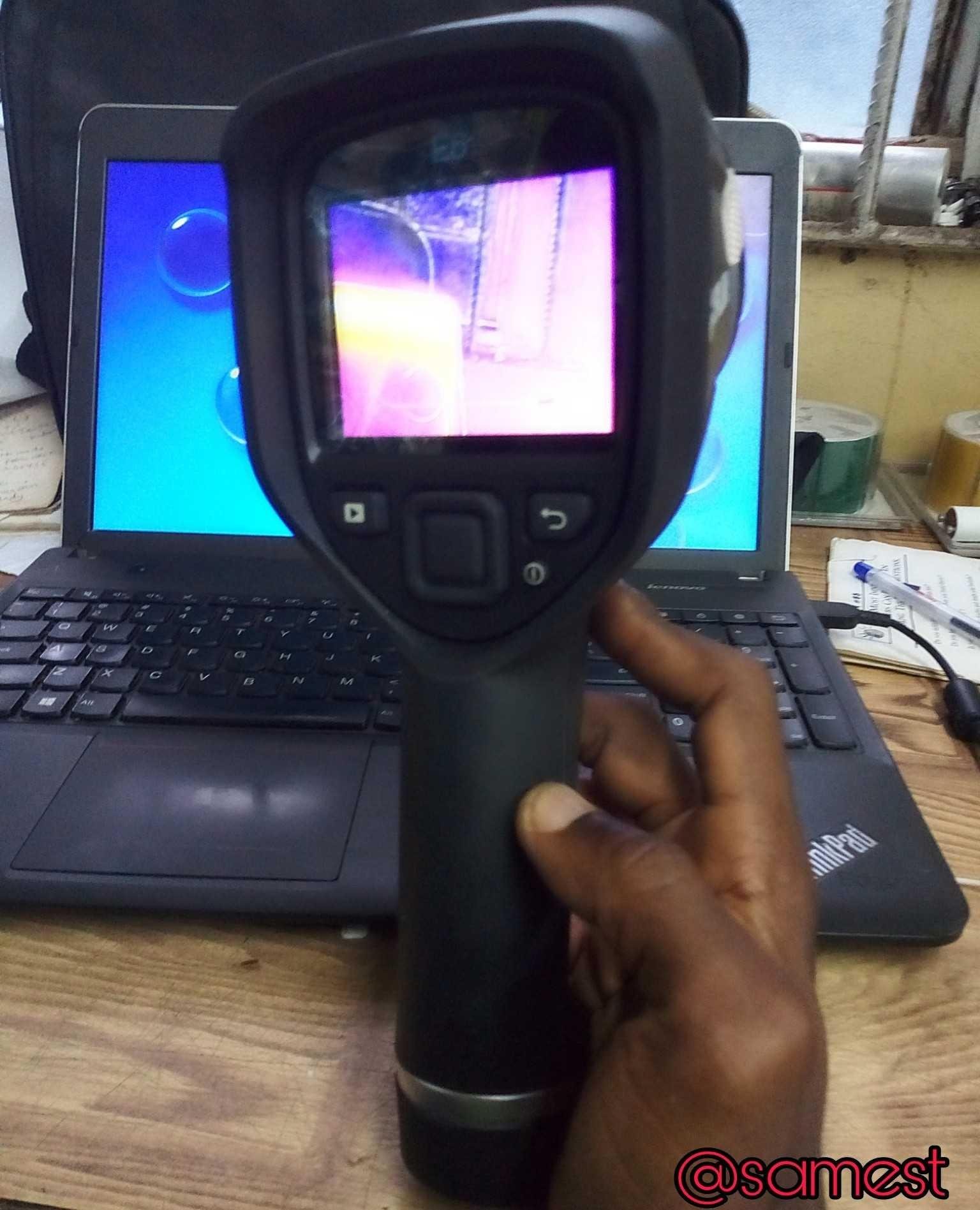

Some electrical problems are not immediately recognizable during a visual-onlg inspection. The typical example is the image below.

This trouble can't be discovered except the use if infrared thermography (Electrical Instrucment) to view the connections while under load. When one of three conductors is observed to be cold (no supply) on a 3-phase balanced load, the electrician duty is to energized and look at the system more closely for the trouble.

From the above picture display it reveal that, possibility of installer to mistaking terminate one conductor onto its insulation that is never stripped.. This is part of trouble electrician should look out for in an electrical system should incase 3-phase balance supply not complete to the load side.

- Trouble 3: Excessive Moisture/active leak

This is very common occurrence with many types of electrical system/equipment. In my engagement many things can cause excessive moist or leak and long term excessive leak can result to major electrical outage.

The source of water could be roof leaks, chilled water lines condensing on the equipment, plumbing supply or drain line leaks.

The image attached can be traced to this problem: water leakage from the top of busway and busway switch. The rush display on the pipe shows that this has been leaking for a very long time, the danger in this is that once the corrosion penetrates the top enclosure steel, water will run directly onto the busway splices and cause phase-to-phase and phase-to-ground arcing. These failures usually result in arcing ground faults that destroy several 10-foot sections of the busway. Fire and fire-sprinkler water damage also commonly occur and can cause significant business interruptions.

- Trouble 4: Overheating

When you look at the image displayed, the white conductor insulation on the 2-pole breaker shows signs of overheating. The insulation is black and burned at the breaker screw terminal.

This damage can be seen during a close visual inspection. On the other hand if thermographic inspections had been used as part of the periodic EPM (Equipment Preventive Maintenance), this failing breaker or termination would have been seen much sooner before the insulation became heat damaged. If this is not quickly attend to it can cause electrical fire.

- Trouble 5: Breaker Spring-clamp Location

Visual inspections should include checking panel board connections where the breakers spring-clamp onto the panel board bus bars. The integrity of these connections can always be checked using periodic infrared thermography.

When this fault on panelboard were not checked, it will advance to a catastrophic panel board loss due to phase-to-phase and phase-to-ground arcing faults that melt sections of all three of the bus bars. The melting of the steel enclosure typically occurs before the overcurrent protection opens the circuit.

From experience it is certain the arcing will start at one phase, the initial ionized air and arc plasma will quickly conducts to all of the other phases and ground. So, damage can occur where electrician least expected, it is mandatory for them to always look for trouble and clear it off.

- Trouble 6: Switch by the Cover

Sometimes electrical equipment looks perfectly fine from the outside. You might assume that if the outside is clean, then everything inside must be okay too. In reality, the display image is a perfect example while periodic visual inspections are so critical to the reliability of electrical equipment.

Spiders can get into enclosures through holes in enclosures that are small and normally do not present any unwanted access problems. When dirt and moisture collect on these spider webs that bridge phases and provide paths to ground, conditions are ideal for flashovers and arcing ground fault damage. When arcing ground faults together with products of combustion as result of dirt on the panel can result to contamination to the adjacent switchgear sections. Long lead times for new switchgear can create unrecoverable business losses.

- Trouble 7: Motor Overload

Visual inspections should always include checking that the motor overload protection is set properly based on the motor nameplate amps and the manufacturer's setting instructions supplied with the overload relay.

Originally, the two IEC motor starters and overload circled in the panel displayed were identical. One of the motor controls were replaced with a different unit that does not have a settable range to protect the connected motor. Motor overload relays that have an adjustable range of amp settings can easily be set to a value that will provide no overload protection for the motor. When replacing motor overload relay it is advisable to look for professional to attend it replacement of overload. It takes a professional to know that motor overload relay with one overload heater element per phase cannot be changed without physically replacing the three heater elements. These type of motor overload relay are less likely to be accidentally set to the wrong amp values.

As a matter of trouble finding, electricians must look out for improper field modifications and rectify it asap, because this simply means the motor is not protected against overload and damage will occur if continue to make use of the motor.

How does Infrared Thermography Works

During my discussion above infrared thermography is one of the major instrument i mentioned when considering trouble finding.

What is Infrared Thermography?

This is my infrared thermography

This can be define as the science of detecting the energy emitted (infrared) from an object and performing the function of converting the emitted infrared energy then display the result as infrared image. So for better understanding, Thermography is the production of image via temperature while infrared is beyond red.

|  |

To use this instrument/equipment is very simple all you need to do is to turn the camera on and since is infrared you don't need the equipment to move closer and make contact before capture thermal images.

You can read more about Infrared thermography Here: What is Infrared Thermography by: Flir

In conclusion, some electrical problems are from self-inflicted wounds. As a manager or engineer you may have all processes and maintenance schedule in place but the question is; Who is allowed to do electrical work at your facility? Do you have a qualified peraonnel? Look at the image displayed, would a truly qualified electrician install a copper wire in place of a proper fuse?

If unqualified personnel are performing electrical work in your facility, they are exposed to serious danger. In addition, their unsafe acts may cause injury to others who work nearby or are affected by their improper electrical installations. Regardless of how this installation occurred, routine and periodic inspections can discover problems and allow corrective actions to be taken before a fire, injury, or equipment damage occurs.

Thank you for reading.

Reference

The Locomotive: Implementing Electrical Preventive Maintenance by Stephen R. Laskey, Hartford Steam Boiler

Water Environment Federation Journal:Preventive Maintenance of Electrical Equipment by William Schneider

NEMA News: The Basic Of Electrical Preventive Maintenance by Emily

.gif)

[Credits: @elvisxx71]

Do you blog on science, engineering, mathematics or technology or you are new on steemSTEM, the please join us on our Discord channel and please check out the posts on #steemstem!