After going through the rules and principles of embodiment design, there are also several guidelines, that might help to keep an overview. They were gathered over time through experiences with different technical devices, and give solutions to reoccuring problems.

These guidelines are applicable in the appropriate situation. So not all products need to consider each of them. That’s why they are guidelines.

Design for Strength

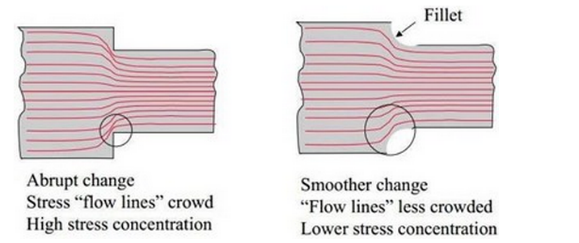

Stress flow is symbolized by lines, that indicate weak spots the closer together they are

The flow of stress and the strength of the material have to be planned. Weak points have to be calculated to estimate the safety ( Safety = Strength of material / Possible Stress).

Design for Controlled Deformation

Deformation can't always be avoided, so it has to be planned for. A good example are the wings of planes which bend upwards during flight.

Design for Stability and Avoid Resonance

the Tacoma bridge is a prime example: the wind was in the resonance frequency of the bridge, which later desroyed itself

Stability avoids toppling of the device or other unwanted movements. Resonance can be avoided by making a device stiffer or heavier.

In ships, all the walls can be tested by hitting them with the hand and listening for a deep sound. The engine in the ship can otherwise lead to an increased shaking of a metal part and destroy the integrity of the whole ship.

Design to Accommodate Thermal Expansion

A gap in a bridge used to compensate for thermal expansion

Mechanical devices are reliant on their geometrical shapes, which can vary with temperature.

An expansion of components can be countered by giving them place to expand and relative expansion between components can be used to cross out expansion. This is done in a pendulum for a clock, where the center of weight has to stay at the same position.

Design to Avoid Corrosion

Sacrificial anodes to protect from corrosion in sea water

If corrosion can't be avoided, due to environmental causes for example, it should still be counteracted.

Even Corrosion: Cause and Appearance

Rust eating away on a car

Corrosion from moisture is influencing every device in wet environments. For metal it can be countered by increasing the wall thickness. The decrease of surface and increased smoothness reduces corrosion as well.

Localised Corrosion

Corrosion always finds the weakspots

Contact of certain metals, cracks in the surface or other irregularities lead to localized corrosion. The appropriate risk have to be found out and measures have to be taken.

Design to Limit Wear

Well oiled runs better

The unwanted release of particles due to mechanical or chemical effects is to be restricted and planned for. It should be limited using appropriate methods like lubrication, surface hardening, restricting motion or other methods.

Design for Ergonomics and User Safety

This ramp was not properly designed

To protect user from the device (and the device from users) they must be protected from harmful effects. See DIN 31000 on how to make the product protect the user from itself and DIN 31001 how the user can protect himself from the device.

Ergonomics ensure safety over a long term use: healthy working position and handling, comfortable noise and vibration levels and much more. Referred here are VDI Richtlinie 2242, DIN 33400, 33402, 33403, 333304, 33413, 33414 for an exciting read.

Design for Aesthetics

Functional and pretty beats pretty functional

Form follows function, but if it doesn't and function is left alone, nobody will enjoy using the product. The other way around makes people question how to use it...it is now art.

Design for Ease of Manufacture and Inspection

A simple manufacturing of the separate components allows for a lower price, shorter manufacturing time and higher safety.

Component Structure for Ease of manufacture

- Differential Design

All in one

A complicated part with many functions is split into multiple parts, each solving one function. While there are more part, the costs for manufacturing may be significantly decreased.

- Integral Design

One for each

Multiple parts and their functions are combined into one part. This can be done if certain manufacturing methods like casting, 3D printing or milling are used. These methods allow for complicated, highly individualistic parts.

- Composite Design

Add and continue

By using a followup of manufacturing methods, several parts with few functions are combined during manufacturing and then further machined.

Embodiment design of Workpieces for ease of Manufacture

The part has to be adjusted for an optimal manufacturing regarding costs and quality. The importance for this increases with the number or parts that have to be manufactured.

Design for Ease of Assembly

Car manufacturers have made the assembly as easy as possible

Since assembly lines, it is necessary to make it easy for the assembly worker to do his job.

General Guidelines on Assembly

At least the money is right

What is bothering a lot of people with working on an assembly line has its reason in increasing performance: monotonous tasks, that can be done with a few movements and little to no variation. Exactly the same reasons the task is easy to do without much specialisation.

Improvement of Individual Assembly

To sum up production planning, it can be divided into the following steps which should be taken into consideration during planning:

- storage: Every part should be stored in the same clear position to avoid unnecessary positioning and confusion during assembly.

- handle workpiece: If the part is used, it has to be safely and ergonomically to move on a short path.

- positioning joining: Symmetry allows impossible false positioning. If symmetry isn't possible, the position should be clearly indicated by the shape of the object.

- arranging: If the part has to be adjusted, make sure that the adjustment is only related to that part and the change is measurable.

- securing: Once the part is installed it should not loosen itself or change its position. This can be done by using self-securing connections or additional locking devices.

- checking: The proper assembly must be controllable with a simple method and without dismantling other parts.

Ensuring Operability and Maintainability

As reliable as a Kalashnikov

The product has to be easy maintained, repaired and inspected to ensure a proper operation. Is it difficult to maintain? Can it be repaired quickly without using many parts? Will a problem be found during an inspection? This also takes into considerations surveillance devices that take data over the operation of the product.

Designing for Ease of Recycling

Don't focus on trashing too much, but keep it in mind

Last but not least, it is important to keep the end of the product in mind. While there may be concerns of regulations regarding the products past life, there are also more and more customers which are concerned about the environment.

Conclusion

With these guidelines there will hardly be a point left undeveloped. Important to nitice is that theses guidelines also try to give an incentive to view the product of the other parties involved in the development. The people in manufacturing, assembly, packaging and so on may appreciate the work, but won't like their work if the engineer doesn't meet them half way.

Thank you for reading!

to be continued

Did you already read…

Part I: What does an Engineer do?

Part II: The first STEP on the way to YOUR Product: Inventing

Part III: The Other Kind of Research: Put your IDEA into the World

Part IV: The Requirement List: The ENGINEERS way of TAKING AIM

Part V: Function Analysis: No Maths but still solving Problems

Part VI: Part Solutions: Solving one function after another

Part VII: Combined Solutions or How to build a spaceship

Part VIII: Comparing Combined Solutions: What is the best spaceship?

Part IX: Embodiment Design - Part 1: The Basic Rules and Principles