Welcome back to the build! If you have been reading previous parts you will know that we have now started the actual build of my life's dream, a totally off-grid sustainable Earthship home. I received an amazing response from international volunteers and could barely accommodate and keep up with the flow of passionate and curious people! I was very fortunate to have quite a few volunteers who also had a lot of experience and skills to share.

One man that stands out is Neil! I didn't know Neil before he came to help us out, and the first I ever heard from him was from a Facebook message. He told me he had just quit his job in the UK as a carpenter and was filling his suitcase up with tools and coming over to help for at least a month! This was amazing news, because not only was I just about to start on the main wood work for the house, but I also had no suitable local carpenters that I had any faith in. One fine day, he just turned up ready to go, with the most useful array of tools that I could have wished for. Sometimes, the right person turns up at just the right time to save the day, and this was a prime example!

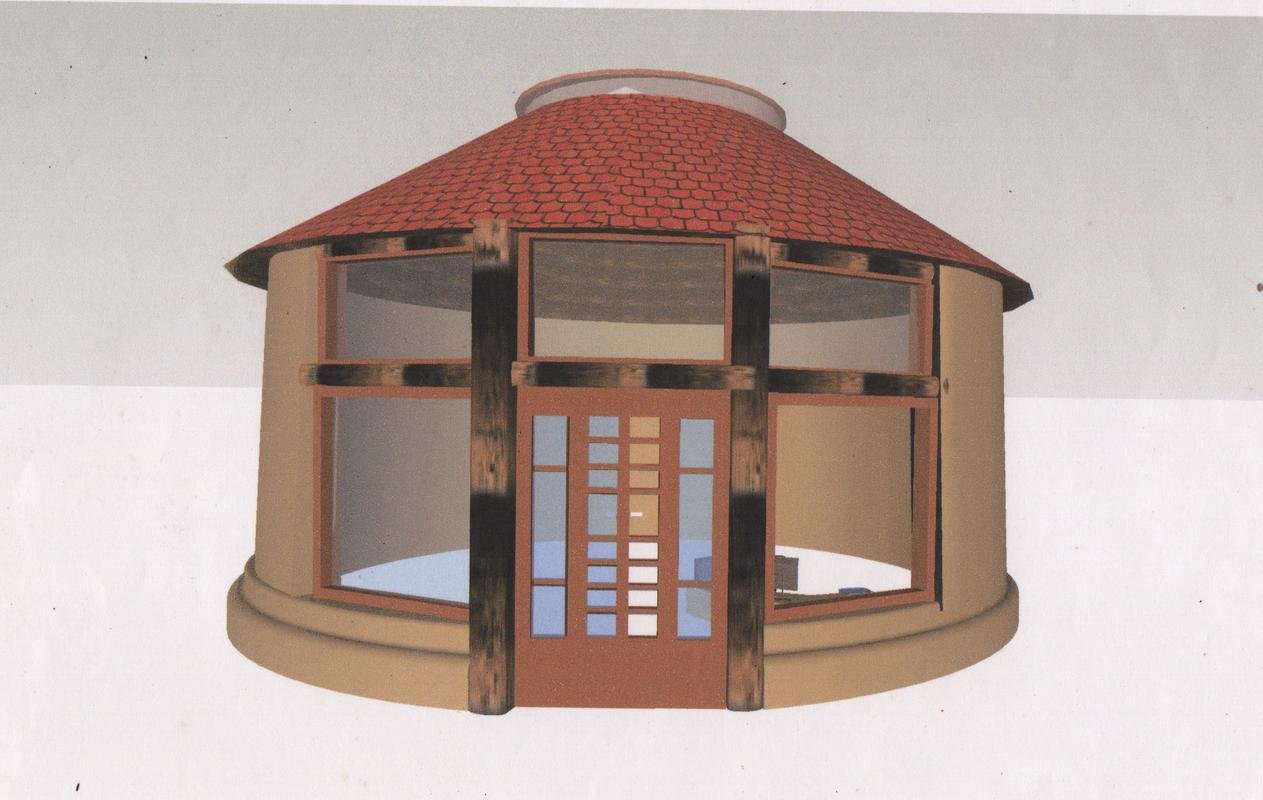

The vision that I had for the Earthship was to have two large wooden pillars on either side of the door and as additional support for the roof.

I had been wondering for some time how I was going to get any pillars here that would be that big! Each one is basically as big as a tree, and it would be almost impossible to bring any here due to the steep inclines and lack of vehicle access. Then one fine day I got a very exciting message! We had a pretty severe cyclone a year before, and two large Eucalyptus trees had felled naturally just at the to of the hill from where I was. Luckier than that was that I had been given permission to buy one of them for almost nothing, provided I could clear the whole thing, including the roots from obstructing a path. I had no idea how big this tree was, so I went up the hill to check it out.

It was HUGE! I would estimate around 200ft in total and completely straight with almost no branches for 3/4 of the length. This tree was absolutely perfect for the job! I did the deal in a heartbeat, and got some guys with a VERy long two- man saw to come and cut it up into pieces for me. Once we had smaller pieces it would be much easier to bring them down the mountain. The two pillars needed to be around 18 feet long each, and so it was clear that I would have plenty leftover for other uses. I was planning to also have mezzanine in the house, and so I decided that I would prop the entire mezzanine up on these Eucalyptus pillars as well! The mezzanine pillars only needed to be 7.5 ft long, and with four in total I would have enough. This whole process happened some weeks before Neil arrived, and a good job too! It took a couple of weeks for a few guys and their blunt tree saw to cut through it all.

Each cut took all day or more, and they were also unable to work full time as they were busy guys! Step by step, piece by piece, we got there; until finally we had around 8 pieces in all ready to shift down the hill. Bringing an 18ft piece of tree down a very steep mountain edge was one of the most scary parts of this whole build. I had around 12 guys and a lot of rope and told them what to do.. well, I told them to bring it down, but not HOW to bring it down. I had assumed they would all pick it up as a team and walk it down the steep gravel track that we have. I never imagined that they would attempt to do it by basically throwing it down the hill and try to manage its descent with ropes that were attached to it. That is what happened!

I stood at the very bottom and couldn't believe my eyes when I saw this enormous piece of tree get shunted down. It was pandemonium! It flew down, then bounced a bit and stopped at various points where it was more level. Each time, I had NO idea if this tree was going to just go all the way down the mountain, destroying who knows what below me, or keep stopping. A few guys almost got knocked down as they tugged on the ropes to try to control it, but basically it was just blind luck whether the piece would stop or just keep going. I couldn't watch, and so I didn't. I just went down to my Dome and listened to the shouting and screaming as they told each other what to do.. and could literally feel the ground shake as each piece came down to the level. Damn! We did it, no wood lost, and no small villages destroyed! We had enough wood for the job and a great carpenter ready to help us install it.

Now I come to think of it, the most scary part of this project wasn't bringing the tree pillars down the hill, it was standing them up! I will never forget that day! We had no cranes or power tools for this, and more or less no idea how best to get these 18 foot tree length up vertical. I had two small holes dug that would receive them and would be filled with concrete once they were in place. Neil was ready and raring to go with a pretty serious carpentry job ahead. He spent a good two weeks cutting the ends straight, and flattening one entire side of each pillar for the door frame to attach to. We did have an electric planer for this, which made this possible. Nevertheless, it was a challenge even for Neil and he did really well!

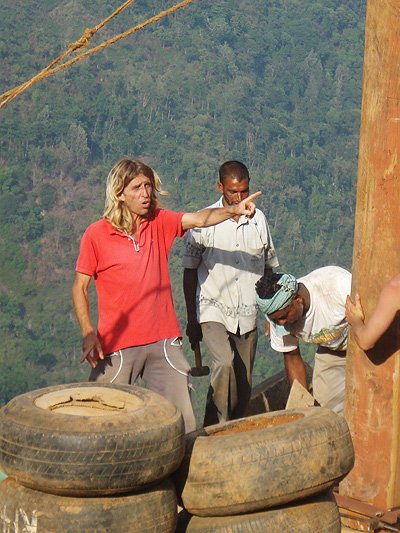

The pillar raising day came. A few of us discussed how best to get this thing up, and we agreed that we would try by just attaching ropes and all of us would pull them to raise the tree. The first attempt failed! It was damn hard to lift this tree, even with 25 people all pulling on ropes attached to it we could barely get it up, and when we did manage to we couldn't keep pulling all the way. Therefore we decided on a step by step approach of lifting it a bit and then supporting it underneath with tyres to hold the weight. We could just keep stacking tyres up under it until it was high enough to pull that last bit to vertical. It seemed like the best way to go, and we had plenty of tyres! Rather than try to explain how tricky this was, I'm going to show you some photos instead!

We haven't got to the scariest part yet! The fear moment happened the second we successfully got the tree up to vertical. It was an amazing moment, and took every ounce of strength from all of us to achieve it. The moment we got it up, we realized that we didn't exactly have a plan what to do next! We we all there holding this thing in the balance, each pulling against each other to keep it upright, and a few people right on the tree holding it. There was a little bit of panic and it was clear we had to tie these ropes to some anchors to hold it up and then start to fill the hold that the base was in with stones so it was wedged in. Everyone held on to their ropes whilst a few of us stabilized things until finally we were ready to take our hands of and see what happened! It WAS OK, it never fell ;-) We managed to raise the second large pillar much more easily, but it was still damn hard! These pillars would be stabilized at the top by a concrete bond beam, so eventually they would be very stable.

This is a very good point to mention something about working with wood. Whilst wood is stronger than Steel in some ways, it is also very vulnerable to wood rot and other kinds of damage. I did take some precautions against this, by using a tar based paint to cover the ends of the wood, and a tar sheet on its base where it made contact with the concrete in the ground. Nevertheless, it was a mistake to do this, and I have had to do some significant maintenance since then to cut out and repair rotting wood up to 1 foot below ground level. I have even had to install large metal braces to ensure that they don't drop if the base does rot totally. Oops! Looking back, I'm surprised Neil never mentioned this to me, and I had no idea about these things at the time. What I have learned since is that the best way to do it would be to install a 2ft square shaped stone base foundations, so that the pillars would be above ground level and sitting on these stones. That way they wouldn't be in the ground and vulnerable to dampness, even with concrete and tar around it. The same thing applies to the mezzanine pillars, that were all installed the same way! I had three of them rot at the sides or base, and have since repaired them and they seem OK now! I guess this is one of the drawbacks of working with very custom designs, and volunteers! You have no comeback after the event, and there is no way I could ask Neil to return and fix the problems.. We did manage to do the work with some carpenters from Auroville who turned out to be pretty good.

Whilst all of this was happening we were of course always ramming tyres and continuing with the walls. They seemed to go up relatively easily, and without any hitches. The main issue was that I had to always check every single tyre for alignment and compaction. I would always be OCD'ing on this, and you could often find me nudging each tyre an inch this way or that way. We we also filling the gaps on the side of the wall wth a Cob mix of mud, water, and coconut hair. We also used stones to help fill these gaps and mixed that with the mud. We kept on packing these gaps with mud until the wall was almost level.

As you can see, we had people of all ages working on the tyres. I wasn't in a rush and really enjoyed doing it in great company and good spirits! We had great music, good weather and lots of energy to pound almost every day. Sunday was a day off!

If you are interested to read about building code and how to build using tyres, please check this link out

http://earthship.com/tire-building-code

Here's a Lovely Earthship Tour of a Global Model Earthship In Taos, NM, USA.

MISSED A PART?

CATCH UP ON PARTS 1-6 HERE:

Part 1: The creation of my life's dream, a totally off-grid self sufficient home - Earthship Karuna

Part 2: The dream was born.

Part 3: How to accomplish anything in life!

Part 4: Finding My Spot in India at Last! The Journey Ends and Starts!

Part 5: The Remarkable Diary of an ecoBuilder. A plan and vision was born

Part 6: A Diary Of My First Eco-Build Of An Off-Grid Sustainable Earthship: - We Start Building!

Don't Want to Miss the Next Remarkable Diary Post?

Click here to subscribe to email notifications and nothing else

Click here to see more amazing posts from passengers on the ecoTrain