Hi! guys! Yes, you heard it right! We know that the 3D printing technology can make highly complex and customizable products. I wrote a little on 3D Printing in a post here. 3D printing made products via a layer-by-layer additive process. So what exactly is the 4th dimension? The physics guys will know the answer. Yes! It is TIME! But what do I mean by time? Let me show you.

4D printing, one of the coolest technology in town

Skylar Tibbits, a designer, artist, architect, scientist, all-in-one coined the term, 4D printing. You 3D print a product that can change its appearance like shape, color, size, etc, over time when triggered by something in the environment. This "something" can be anything like water, heat, light, pressure, etc. And the key to unlocking the appearance transformation lies in the “programming” of such “smart” materials. As a materials engineer myself, I can imagine three challenges for materials scientists.

First, it is difficult to 3D print new materials and composites because we do not know the optimum parameters (e.g. transition temperatures, melting rate and cooling rate) to 3D print them and form a product. Then, what comes next is the ability to program this function in the materials design. Last of all is that, after the 4d printed products react to the external force, there tend to be a degradation in the mechanical strength and this means that they might not be able to maintain their function performance as intended. Hence, materials scientists face exciting challenges to design new materials and composites that can be both 3D printed and at the same time, smart.

Let’s have a look at what the researchers are doing in their labs!

See how the smart coil amazingly forms the word "MIT" in water

Or how the plastic tube forms a different shape when immersed in water.

Or imagine when you drop something and it re-assembles by itself miraculously...

Smart Products made from 4D Printing

So now, we know that 4D Printing fabricates smart products made up of smart materials! What are the possible applications that 4D printing can have?

Biomedical applications

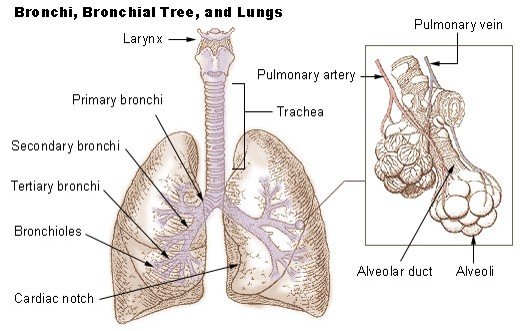

4D Printing has one of its successful products in biomedical applications. A sixteen-month-old baby, Garrett Peterson was born with a defect in the bronchial tubes which resulted in breathing difficulties. This was a particular challenge for biomaterials scientists who seek to 4D print a splint. First of all, a splint should be flexible as the body moves and the shape is also highly customized. The splint must also be able to help open and hold the airways for two to three years before it becomes normal. Then, the splint must degrade at the optimum rate as the air ways become normal. There are of course, other biomedical implants which require similar functional performance and ability, and 4d printing may be the perfect process to make the implants.

Electronic gadgets

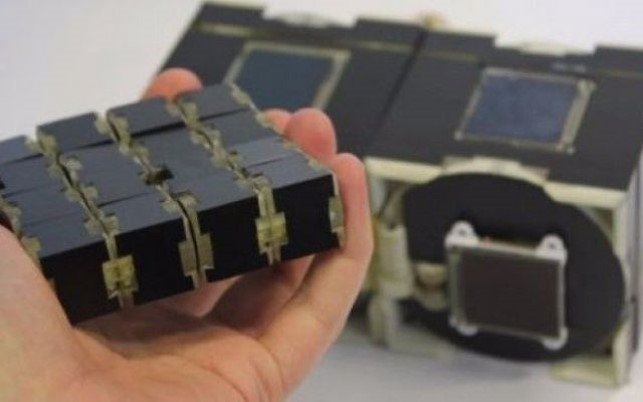

Imagine your mobile phone transforming into any shape you want? Here it is! Cubimorp is a shape changing electronic device developed by the researchers at University of Bristol. When you press an app, it can change the shape of handheld electronic devices accordingly to how the app wants the shape to be. You can even change its shape to your preferred mobile shape.

Clothes that change colors

The idea of clothes changing colors comes from an animal in nature - The chameleon! Imagine if the color of your clothes can blend in with the environment! This is biomimicry at its best! This potential application is particularly useful for military clothing which is worn to hide from the enemies. Or for ladies, imagine wear a dress that changes color as you walk! Totally cool!

Cool applications in 4d printing, isn't it? As promising as it sounds, there are still many more challenges in 4d printing and I look forward to sharing some with you in the future. If you are interested in 4d printing, please consider giving me a follow.

Images credits for gif: 1, 2, 3

Follow @coinbitgold blog in science, academia and academiaspotlight