As I told you in my last post, Kathi and me met up in the colonial village of Salento over the weekend. But Salento is not just a colonial city, the region is also very known for its coffee!!

Of course we went to learn more about this process! For us as coffee lovers it was a must, especially being in Colombia

So the next day we took a Jeep from Plaza Bolivar to the coffee Finca "Finca El Ocaso", which is about 3.8 km away from the town and offers a guided tour in Spanish and English about the traditional process of sowing, production, benefit, marketing and preparation of a Special Sustainable Coffee.

This typical peasant farm has coffee trails where you can see the biodiversity of a coffee crop. It is perfect to learn more about the coffee culture.

In general we have two commercial types of coffee - Robusta & Arabica.

Each have their own properties and qualities. The main difference is that Robusta is easier to grow, more ‘robust’ like a Trojan horse, but the coffee bean is of a lesser quality. Arabica produces a higher quality bean, but is more ‘complicated’, a delicate plant that requires the optimum conditions.

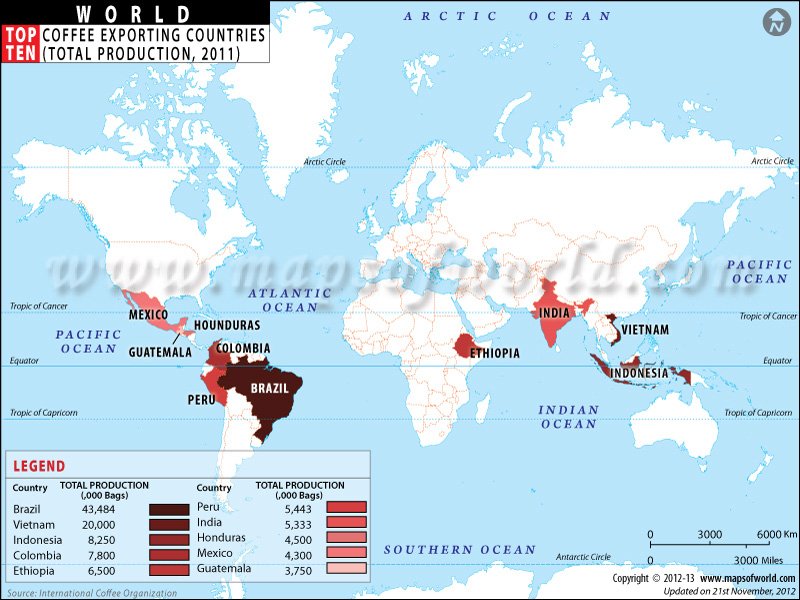

Colombia is number 4 of all important countries that produces coffee and export it, growing mainly Arabica and a bit of Robusta.

Brazil is the number one producer and exporter of coffee in the world. They produce 1/3 of the worlds coffee, majority of which is Arabica, a little being Robusta. In second place we have Vietnam! Vietnams coffee is considered ‘low grade’ as it is mainly Robusta with some Arabica. Third and Fourth are close. But third place belongs to Indonesia, which produces Arabica and Robusta. Next up in fifth place after Colombia is Ethiopia. Where coffee was first discovered. Ethiopia produces mainly Arabica coffee.

So as you can see for us it was really interesting to visit one of this Coffee Fincas and learn about how a cup of coffee even can be made.

Getting there we took the Spanish tour with Marco, who gave us a wodden basket and started the tour right away. Here is what we learned that day about the process of making coffee:

Coffee from Seed to Cup

The process from seed to cup is quite a lengthy and difficult process. So next time you have a great cup of coffee, I want you to appreciate it.

The coffee plant likes shade. It doesn’t need it, but it likes it. This means that with shade, more moisture is kept in the soil.

The shade typically comes from trees. Traditionally a row of trees is planted, then two rows of coffee plants, then trees again. Repeat. Plantain or banana trees are usually used. They provide great shade with their large umbrella like leaves and the fruit doubles up in use for consumption, in EVERY SINGLE COLOMBIAN DISH.

Coffee Farms don’t have a perfectly manicured look as you would with a vineyard or an orchard. They are raw and rustic looking.

A ‘parchment seed’ is planted in 1m by 4m growing beds filled with sand. The sand is the best growing medium for when coffee plants are propagated because it allows the roots to grow straight and strong.

Within 4 weeks Colombian time (12 weeks real world time) the coffee plant has reached the height of a matchstick.

The parchment around the seed protects it from external elements.

After 16 weeks the plant is given a sweet name of ‘Chapola’. At this stage it is time to change homes/growing medium as the sand doesn’t have enough nutrients. This is when the roots are visually inspected. Any kinked, spiraled, or broken roots are discarded and used as compost.

The Chapola are moved to individual black bags with a 50/50 mix of black soil and fertilizer. The delicate process involves the use of an empty beer bottle to prod a hole in the growing medium for the new root system.

After five months the plant will grow to 15cm. After nine months the plant will be 40cm tall. At this point the plant should be forked at the top with two branches meaning it is ready to be put in the ground with more fertilizer and plenty of water.

The coffee plants are planted every metre. The coffee plant then grows all year round. Nine months later, or after 18 months from the seed being put into the sand for the first time, the coffee plant should have a height of approximately 1.4m and will bloom.

The flower is white, has five petals and is self-pollinating. No need for the birds and the bees. The flower lives longer than a butterfly but still dies after three days. But it dies for our enjoyment and consumption as this is when the green coffee fruit forms.

The coffee fruit stays green and grows for nine months until it becomes red or yellow (depending on the variety), which signalizes the time to harvest. These are known as ‘coffee cherries’.

The coffee pickers, for lack of a better term, pick the coloured cherries in a trendy whicker basket, sometimes plastic. The baskets hold up to 10kg worth of cherries. Our guide asked us to do that while walking through the big plantation, so he can show us after how to proceed.

Once we got enough we went on to empty them an ingenious coffee pulping machine designed and patented by Douglas Gordon. This machine separates the cherry skin and the two glorious seeds within.

Two things happen here. Some seeds begin to float. Others sink. The ones that sink are the keepers. Anything that floats is considered a bad seed and are immediately removed with a sieve for questioning and composting.

The second thing that happens is the water begins to turn brown as the delicious sugary film is removed. The water needs to be changed 5-6 times before all the sugar is removed. This process takes up to 18-72 hours. This ‘sugar-water’ can then be used to make alcohol. Delicious ‘coffee wine’ and ‘whiskey’.

By this stage, the seeds are clean, but have now absorbed plenty of water and weighing more than they should but lose this additional weight by being dried in the sun.

Any flat surface is used to dry seeds, however there is a slight problem here as the seeds are harvested and washed in the wet season, so typically they are dried in green houses. They can be dried up to one foot deep, but need to be turned constantly to ensure the ones at the bottom get their time in the sun.

Before they can be sold or replanted, the coffee seeds are inspected by hand and any seeds with defects are removed.

The beans are then sorted by size and sold to a wholesaler by the sack. A wholesaler would grab a handful of beans and rub them together in his hands. He does this to remove the skin to reveal the seeds in their green form. If the skin comes off easily, it means the seeds have been properly dried. If it is hard to remove the skin, it means that the beans are still wet. The beans are sold by the dry weight, thus a wet bean will affect the weight and will therefore not be bought.

Roasting is done when the coffee is in its green form. No oil, no butter – a dry roast. This can either be done in an oven or on a stove.

On the stove the green beans are thrown into a wok and stirred constantly with a wooden spoon. It takes about 10-20 minutes. In this time the seeds begin to darken, first to a caramel and then a deep chocolate brown. The darker the roast the more bitter the coffee, which also means, less caffeine. A good grade of seed is needed for a chocolate brown.

You know he seeds are ready when you hear them cracking. You could say that roasting coffee is like a combination of cooking steak and popcorn. At the point when the seeds stop cracking the heat should be turned off.

The seeds should continue to be stirred until they stop smoking. After this they are put onto a mesh net and shaken to remove the remaining skin.

Only after this should they be taken out of the wok and allowed to cool. Then inspected once again for defects.

Here they continue to cook inside from the residual heat.

Here is the best part – the smell. The rich coffee aroma grows stronger as the beans get darker. If you have ever licked a rainbow, the sensation is similar to that!

Once you have your roasted beans, you need to grind them into ‘ground coffee’.

The ratio is 10% coffee to water.

Use 8g of ground coffee for an 80ml cup of water. This is approximately 1 tablespoon.

Once the coffee is in the filter, flatten with the weight of the spoon, but not too hard, otherwise the water will not filter through.

Do not use water that is boiling. Water should be between 91°C and 96°C, or to gauge by eye – when the small bubbles begin forming.

When pouring the water through the filter, the more foam on top means the beans are more fresh.

And then finally you can enjoy your cup of coffee like we did! And it was deliciouse!

It is really amazing how much work it is to make coffee. In our consuming world we often forget where our food and drinks are coming from and take it for granted to get them everywhere, ready to consume.

I think it is important to get to know more about these kind of things.

As always I hope you enjoyed reading my post and I appreciate every Upvote, Resteem and Comment, as you are supporting my travels with it!

Cheers,

Liz

Colombia Part 1: Bogota D.C. - A city full of history and culture!

Colombia Part 2: Guatavita Lagoon, The Muisca Civilisation and The Legend of "El Dorado"

Colombia Part 3 - The Salt Cathedral of Zipaquirá

Colombia Part 4 - Adventure time at the Natural Pools of Guejar River in the Jungle

Colombia Part 5 - Flying to Macarena National Park being a Copilot ✈

Colombia Part 6 - The Rainbow River at Macarena National Park

Colombia Part 7 - Riding Motor Bike and Chilling in the Pools of the Tatacoa Desert

Colombia Part 8 - Enjoying civilization in Cali!

Colombia Part 9 - Living with the president of the orchids club,helping her out at the green house

Colombia Part 11 - Visiting the typical colonial city of Salento