With such a long lead up, and slow beginnings, the main phase of the build went very quickly and painlessly. When I say the main build I mean the walls and main house excluding the roof! The roof was without doubt the most challenging part of this remarkable build! We will come to that shortly.

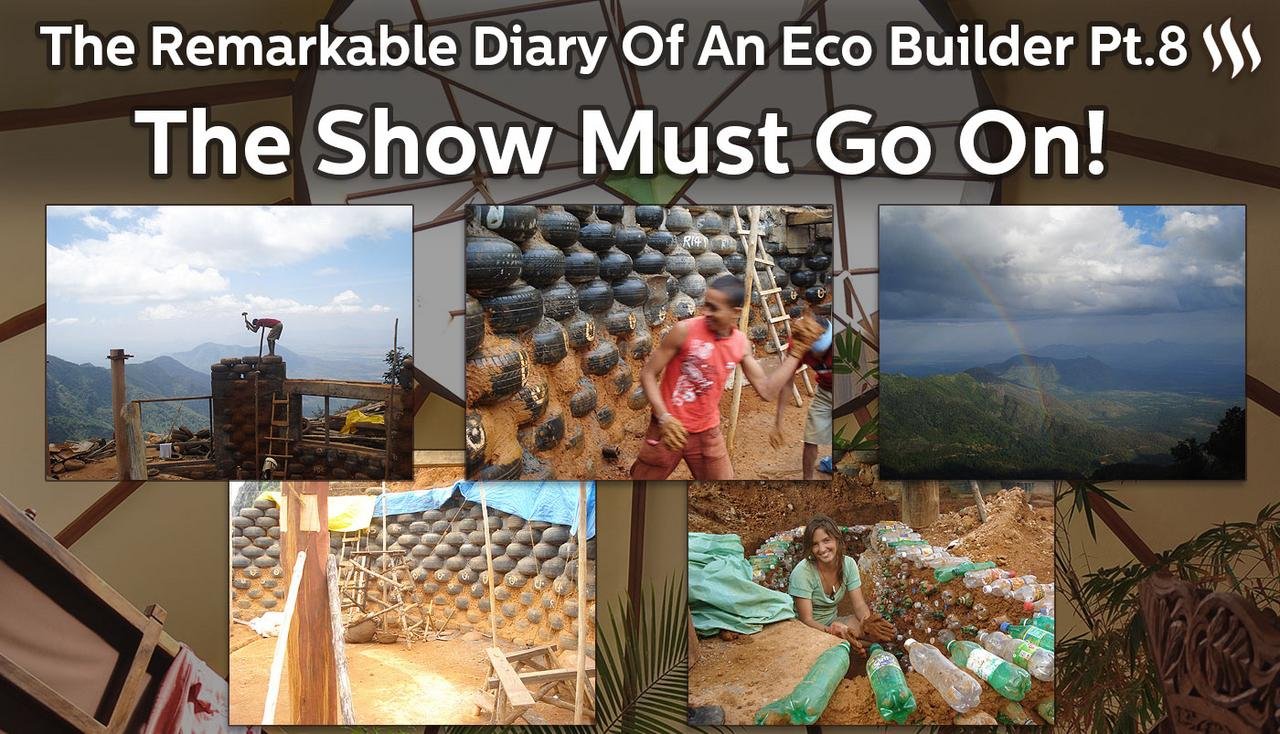

We had around 20 volunteers and a backbone of 6 Nepali working on the tyre ramming. It was quite repetitive and easy since it was just one large circle. The mood was high and no one was daunted by the work ahead since most were volunteers who would generally stay just a few weeks at most. The Nepali love to work and they were totally into making this crazy tyre structure with a bunch of International people. There was lots of comradery around, and many lovely exchanges between us all. In truth, most of the tyre work happened by the Nepali hands! Volunteers do make a great contribution, but you can't compare the amount of work, or the quality of the work. The Nepali could just about do an entire course of tyres in one day. We had a total of around 18 courses and so this work did go quite quickly. It didn't happen in 18 days though! Not even close. There were many breaks and fiddly bits to deal with, and so it took around 6 months to get to the final course.

There was also a lot of other work happening at the same time. Neil our amazing English carpenter worked very hard on the mezzanine structure that was built in to the walls for support as well as using the many wood pillars we had leftover from that 200 ft tree! Neil did an amazing job and under hard conditions. We also set to work on the indoor botanical cells. These cells are large planters that will hold stones and water and soil for the plants to grow. I was very fortunate that Ms Kaila Binney turned up and was totally ready to help me make these planters using plastic bottles and mud. These bottles walls would finally be plastered over and would look very nice (we hoped!). What Kaila did is really amazing. I would come out in the morning and she would already be hard at work all by herself digging and making cob to bind the bottles together with. I can't really thank Kaila enough for her contribution to this project.

The digging starts for the planter cells. These will contain plants that grow and produce food inside the house.

The 6 ft deep hole is dug!

Nepali are still ramming tyres of course

Tamping the ground nice and tight.

Mezzanine framework is up

Mixing cob!

|

|

Kaila Binney Starting the walls of a planter cell using plastic bottles and mud.

These planter cell walls will be plastered over with a thin coat of cement to cover the bottles and provide strength.

Kaila, you are amazing! She did this almost single handedly!

This will be one of the front windows!

The Mezzanine

Just for the record, 18 courses is a lot for a tyre wall. Usually they are single story buildings with around 12 courses. Since I was building higher than the recommended limit, I made sure to compensate by pinning some of the courses together with metal rods. I also used some cement in the gaps at the bottom of the wall to provide a bit more stability just in case. Since this was a pure circle, the stability of the wall was also much greater just because of its shape. Finally we created a very strong ferro-cement bond beam on the top of the last layer of tyres that was extremely strong and would stop the walls from falling outward!

The bond beam was one of those tricky jobs. The thing with concrete is that in order for it to be really strong, you need to pour it all in at once. If you let one part dry and then continue you will have cold joints that will be weak spots in the beam. Therefore on the day of the bond beam pouring we had a huge team of 18 Nepali and a few maisoners. The lead maisoner is called Swami, and is the sweetest and special old man that I ever worked with. He is deeply spiritual and very simple. He calls literally EVERYONE Swami, including himself, and it works just fine. Swami in Hindi means 'Teacher'.

Swami is also, unfortunately not the best maisoner and has terrible eye sight. I kept that in mind as we approached the job! The job was quite simple, we had to mix cement, sand, stones and water to make a concrete mix and feed it up to the top of the wall all the way around. The bond beam is 1ft deep and wide, and so we used quite a lot of concrete and metal to reinforce it. As luck would have it, the rains started coming full on whilst we were working. It was crazy, and we couldn't stop! We simply had to finish the job come what may. The show had to go on! Thank God we were working with Nepali, who just brush off a torrential rainpour like it's nothing. They won't take a raincoat or gloves, and just get the job done with a good mood and enjoyment. It went on all day long, endless mixing and shunting concrete up to the top. Swami was able to keep up and his most important job was to see that the level of this bond beam was the same all the way around. If one part of the beam is a bit higher than another part, the roof is going to be wonky!

It was a great day, and a huge relief for me to have the bond beam in place. This ensured that the whole thing was stable and would not ever tumble over. One of the features of an Earthship is that they are Earthquake resistant. Whilst we were pounding the last few courses of tyres, it was a bit concerning how much the walls moved and even swayed! Somehow they never came down, but you could really see how they could vibrate and even move quite considerably and then come right back together. With the bond beam in place, it's safe to say that nothing was going to push this wall over. You could drive a car at it and the car would bounce right off. It has been estimated that a finished tyre wall would last at least 10,000 Years! The degradation of earth rammed, and plastered tyres is so slow that it's almost not really possible to estimate how long they will last. Suffice is to say the walls we were building were the best walls you could probably ever make! They were fire proof, earthquake resistant, the heating system of the whole house for ever, and the materials costed just a few hundred dollars! The tyres were 80% of the material used aside from freely available dirt to build the whole house structure with.

This bond beam marked the end of a great phase of the build! The tyre ramming was completed, and we were ready to start work on the roof! We had to wait at least a month for the cement to cure well, and I didn't want to take any chances by not waiting long enough! It's fair to say I had worked my butt off for 6 months straight, and now was definitely time for a break. Whilst the concrete was curing, I booked a four week holiday to Chiang Mai, Thailand ;=) Thailand was always my favorite place to rest and recuperate. You can be sure that I had my fill of sushi, and Thai Massage as well as a truly pampered time. Looking back, I'm so glad I took this time out, as the next step was going to challenge my skills and patience to their limits! The roof!

MISSED A PART?

CATCH UP ON PARTS 1-7 HERE:

Part 1: The creation of my life's dream, a totally off-grid self sufficient home - Earthship Karuna

Part 2: The dream was born.

Part 3: How to accomplish anything in life!

Part 4: Finding My Spot in India at Last! The Journey Ends and Starts!

Part 5: The Remarkable Diary of an ecoBuilder. A plan and vision was born

Part 6: A Diary Of My First Eco-Build Of An Off-Grid Sustainable Earthship: - We Start Building!

Part 7: Epic Tales Of An Eco-Builder : The 200 Ft Tree Challenge!

Click here to see more amazing posts from passengers on the ecoTrain