For a long time now I have wanted to build robots. I have all the prerequisites in place I know the theory and have access to the tools. Even so, there are some things that makes it more difficult than it should be.

The most important thing is myself. I cannot help but want to do everything from scratch. There is a lot of maker in me and perhaps a little bit of a prepper too. I do like if I know and control every part of the process.

Thus, I started with a simple project, a hand. I started with the things i know best, The physical design. My plan was to then go on to the software part (which would be more or less a copy paste thing from my PhD) and finally do the motor control.

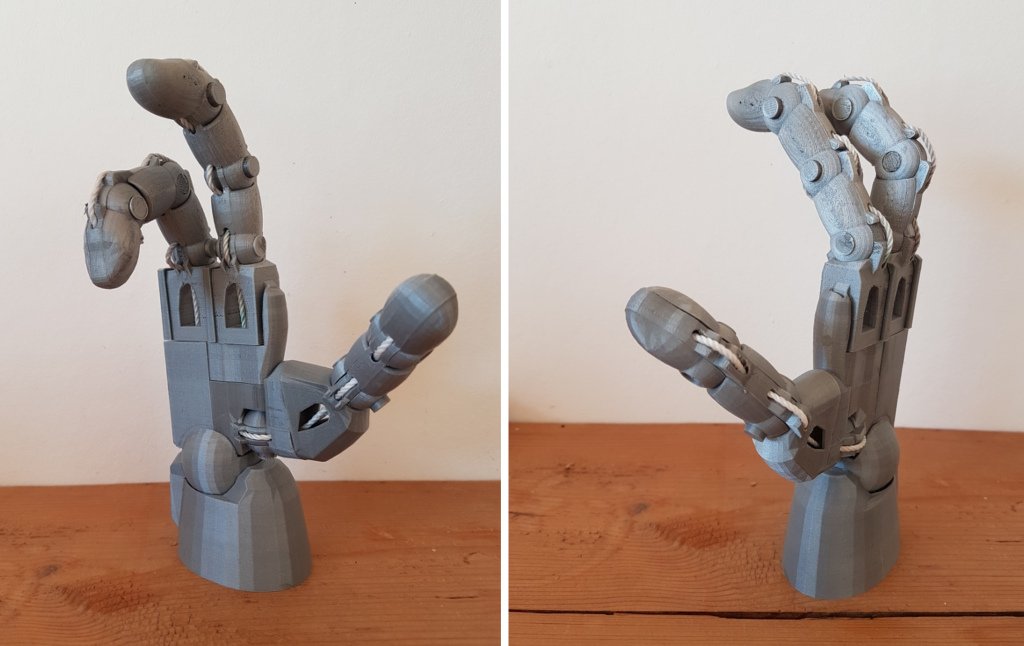

I have worked on and off on it for a few years now and I have come a long way with the physical design. This however is only my first printed design. No motors and no controls, basically a puppethand.

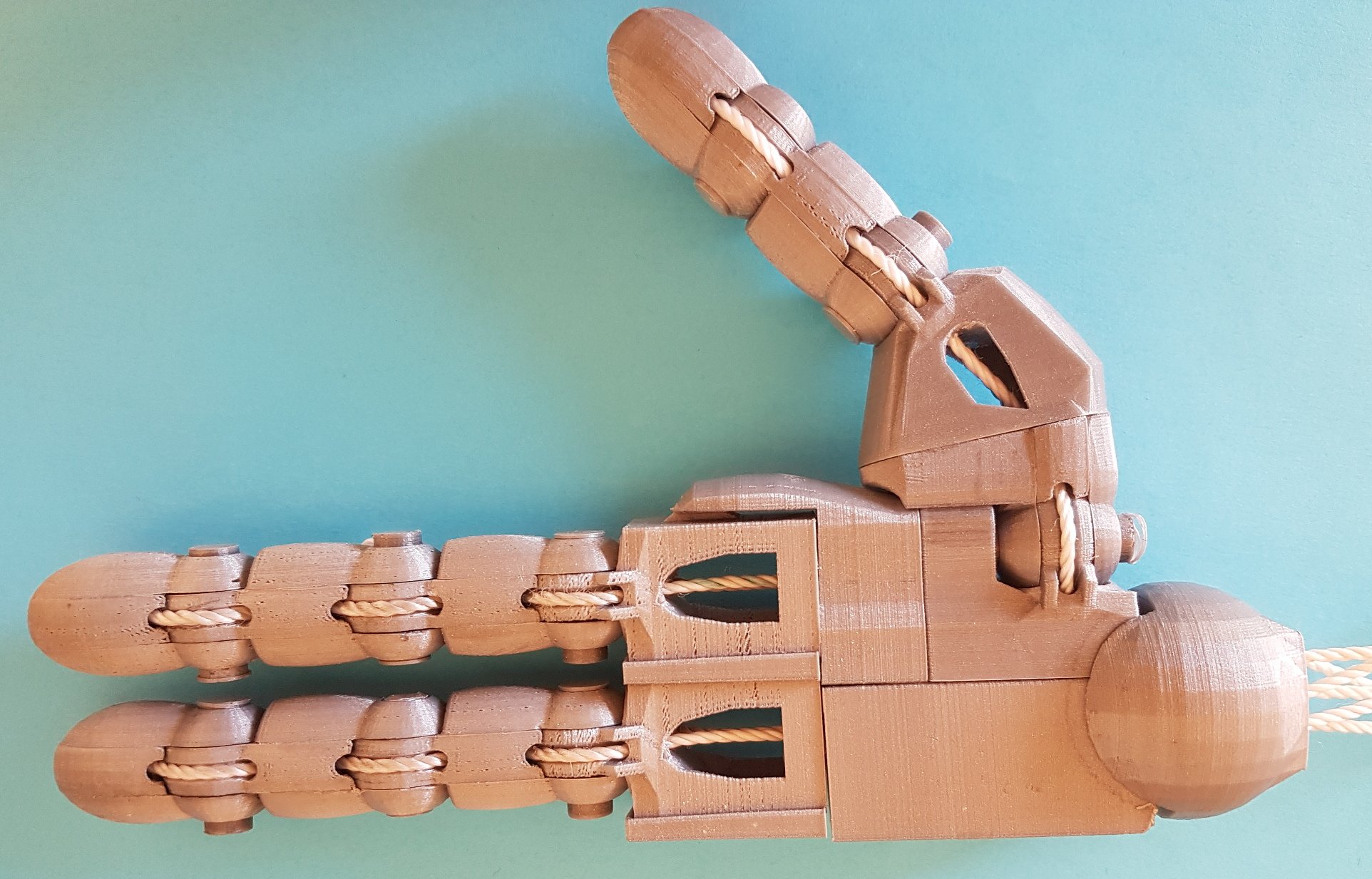

I chose to build the hand as a modular design, that way it would be easier to produce, should i ever get that far with it. All the finger joint are identical, apart from the tips . The base of the hand is made from several components, which can be combined to make more or less fingers.

they can also be replaced with another base to give a different finger configuration.

I used a string to actuate the fingers, and while this gives less control over each individual joint , it drastically reduces the degrees of freedom, which means I need fewer motors to control it.

The idea is that the flexing of hte fingers are done by the motors and the straightening is done by a passive spring. this means that i have control over the grib strength while again reducing the control parameters.

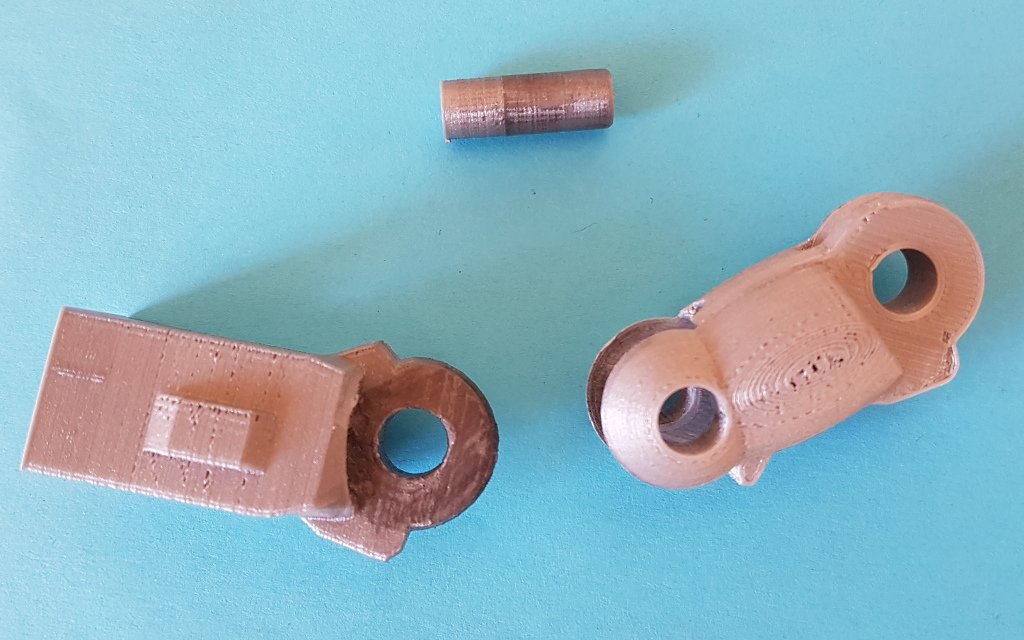

On a finished model the joints would consist of a pin made from e.g. aluminium, but for this early prototype pla was fine. I used graphite(from a normal pencil) as the lubricant . Many types of plastic dont like oil very much, so graphite is a great lubricant for these.

I learned a lot from this early experiment. For one, the hand was far to big compared to what it needed to be, so I downsized my later versions. the fingers where made from 3 parts per joint, which were glued together, and this was real overkill when doing prints. I did it to cut down on the need for supports but I have become better at orienting and designing my prints to get around that problem so i can get by with 1 or 2 parts per joint.

There was also a few good things in this version which I would take with me for the next iterations. The way the wires where drawn through the joints was quite well functioning. No hard corners where the could get stuck etc. The fingers joints was pretty solid so that was good too.

All in all it was a great success and, as one of my early printing experiments, it was quite good. I have learned a lot since then, as I will show you all, in a later post. I hope you like it

Im EvilHippie, a compulsive creative and jack o' trades. If you want to know more about me, check out my introduction post here

If you like what you see, feel free to upvote, follow and resteem

or you can check out these recent posts

wintertrees

delegation

dragon part 2

dragon part 1

ram it

screw it