Why on earth can't we just agree to use the metric system? Recently I had to make some camera mounts for a couple of depth censors. This was part of a research project I am doing with a few colleagues.

The depth censors have standard camera mounting threads so it should be easy to get some threaded pins to use .... Not so. the only way was to either import it from the UK or buy a full camera tripod and cannibalize the threaded pin.

both of these options would be a factor 10 more expensive than the actual bolt, so I tried to find a cheaper solution.

Enter: my favourite 3d-program Blender.

It turns out blender has an in-build addon which does all kinds of threads and bolts. It is called bolt-factory. It does both nuts and bolt.

I installed the addon by opening the user preference tab and ticking the boltfactory addon under addons->add mesh. These addons are really neat and someday I will make an overview of my favourites. For now I will just say: If Blender cant do it look here and it probably can.

I did some research( on Wikipedia ) and found the specification of the thread used in camera mounts. It is the british standard UNC-20 which is a 1/4 inch diameter (6.35 mm) and has a pitch of 0.05 inches(1.27 mm). Pitch is the distance the thread changes in one revolution, so the distance from the top of one thread to the next.

Bolt Factory has some nice presets(but unfortunately very metric-centric). I chose the M6 (stands for metric 6 mm) coarse which is the one closest to UNC-20.

You click the create button and then BEFORE starting to tweak around with the bolt in the 3d view, you set the parameters in the add bolt windows that opens just above the create button. There's options for both the bit type and the head-shape, but these where not needed for this project since it was to be mounted in a fixture.

After making the thread correct, you can go in edit mode and build the rest of the bolt. I just used a cube as fixture so this part was quite simple.

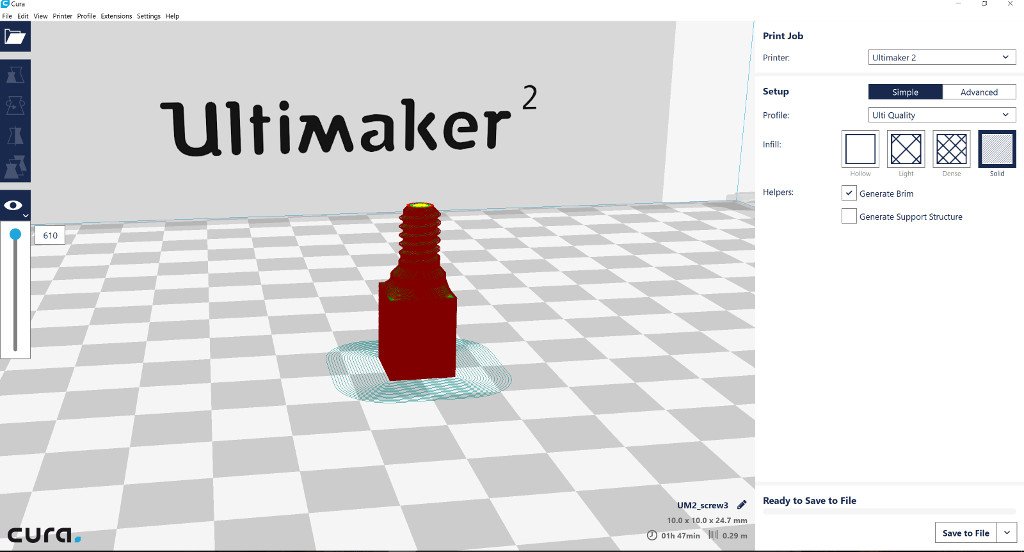

When the bolt was ready in Blender I exported it to stl and opened it in CURA(2.1.3). I wanted to print it on the ultimaker, since the resin from my wanhao gets a little brittle sometimes and this had to be fairly durable.

I chose the best setting (called ulti quality) and chose 100% infill. this was to get the smoothest possible surface and the highest possible durability. I even tweaked the print so that the material-feed was set to 105%. this gives just that little extra material to make sure it is completely solid, without compromising the smoothness of the surface.

Finally i tested the thread on my camera as well as on the phone holder i have got. It worked perfectly and was both tight with no give or rattle, and could be screwed in without any resistance.

if you cannot be bothered to make your own thread, but still want to be able to make your custom cameramount here is an stl of my screw released under creative commons

Im EvilHippie, a compulsive creative and jack o' trades. If you want to know more about me, check out my introduction post here

If you like what you see, feel free to upvote, follow and resteem

or you can check out these recent posts