We are continuing with our series on how to make a beehive out of pallet wood today. We do apologize that there is so much time in between each of these posts, but we are actually building five complete hives out of nothing but pallet wood, and want to show you each piece as we complete it. The project does take time, but the money we are saving and the fact that we are getting a higher quality item is completely worth it. We are coming close to completing the hives, and will do a full wrap up post to show you the finished product. It has been such an amazing experience taking items that would normally end up in a landfill and turning them into beautiful, high quality beehives. We can’t wait to show you the finished hive!

We have covered how to make the frames, boxes, and an in hive feeder in previous posts (links below), and today we will show you how to make the base of your hive or the hive bottom board. It might seem like a pretty easy concept, but there are some important details to consider; stability of the hive, ventilation, easy accessibility for bees etc. This is a design that my husband came up with is for a 10 frame style hive.

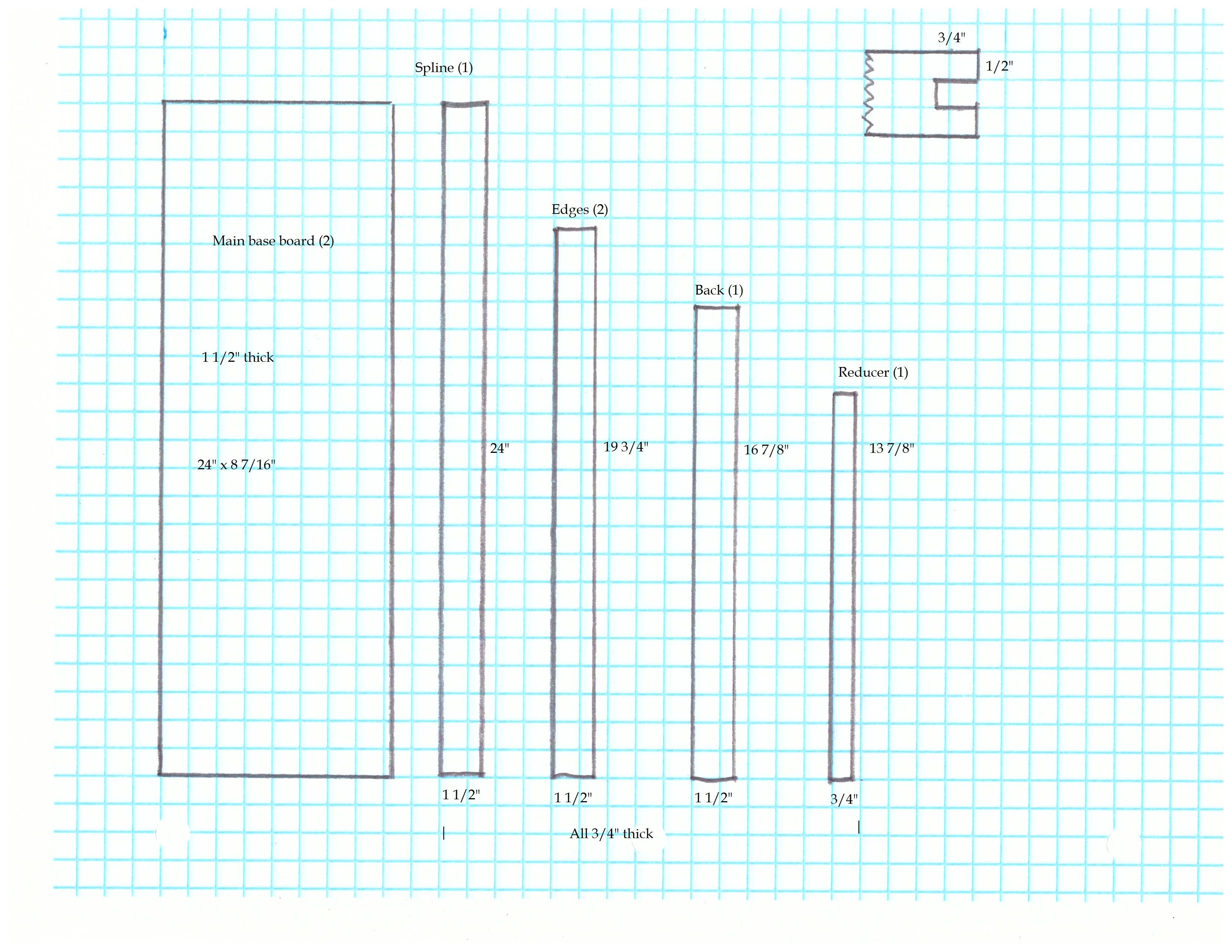

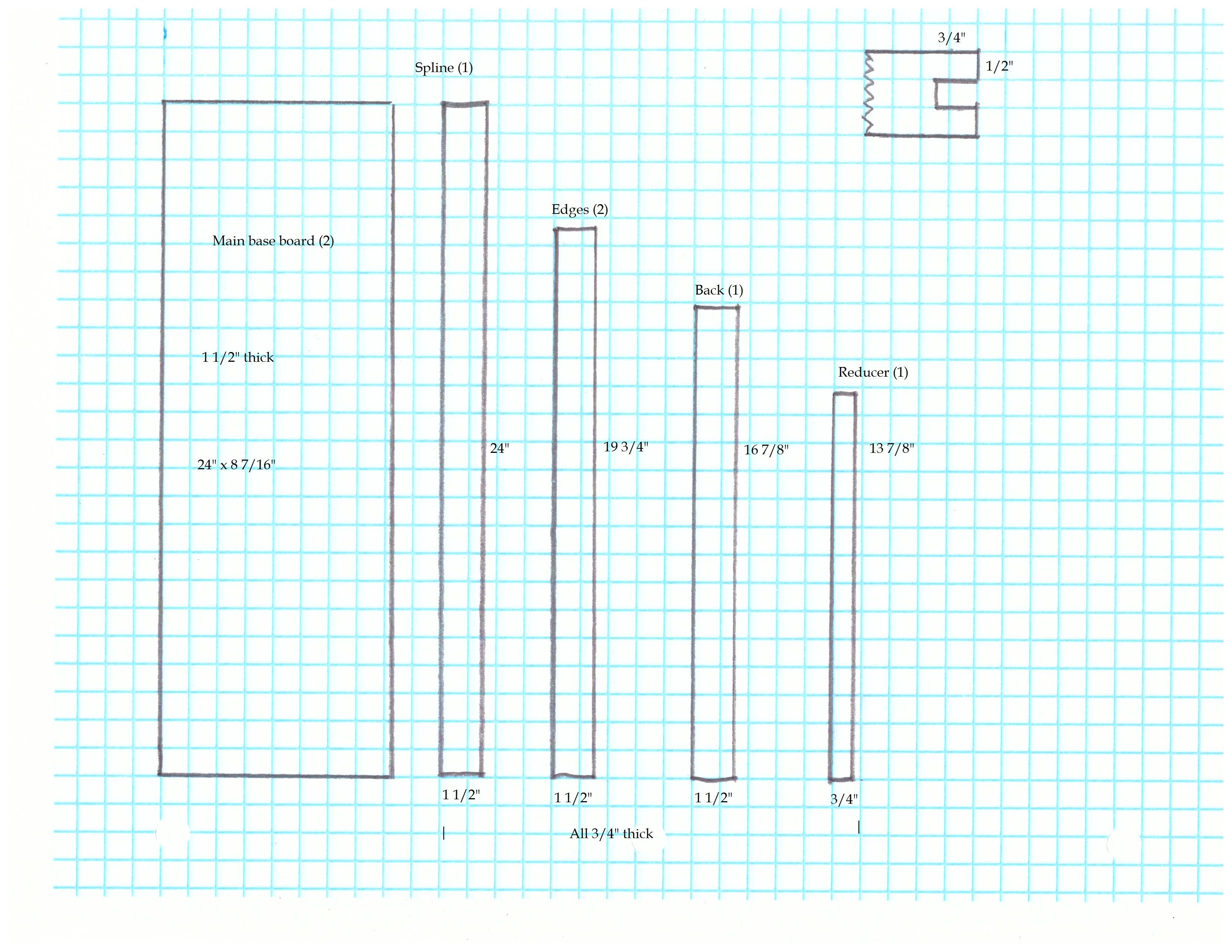

The Plans

- Base x 2 (24” x 8 7/16” x 1 ½”)

- Spline x 1 (24” x 1 ½” x 1/2”)

- Perimeter Side x 2 (19 ¾” x 1 ½” x ¾”)

- Perimeter Back x 1 (16 7/8” x 1 ½” x ¾”)

- Entrance Reducer x 1 (13 7/8” X ¾” x ¾”)

The Process

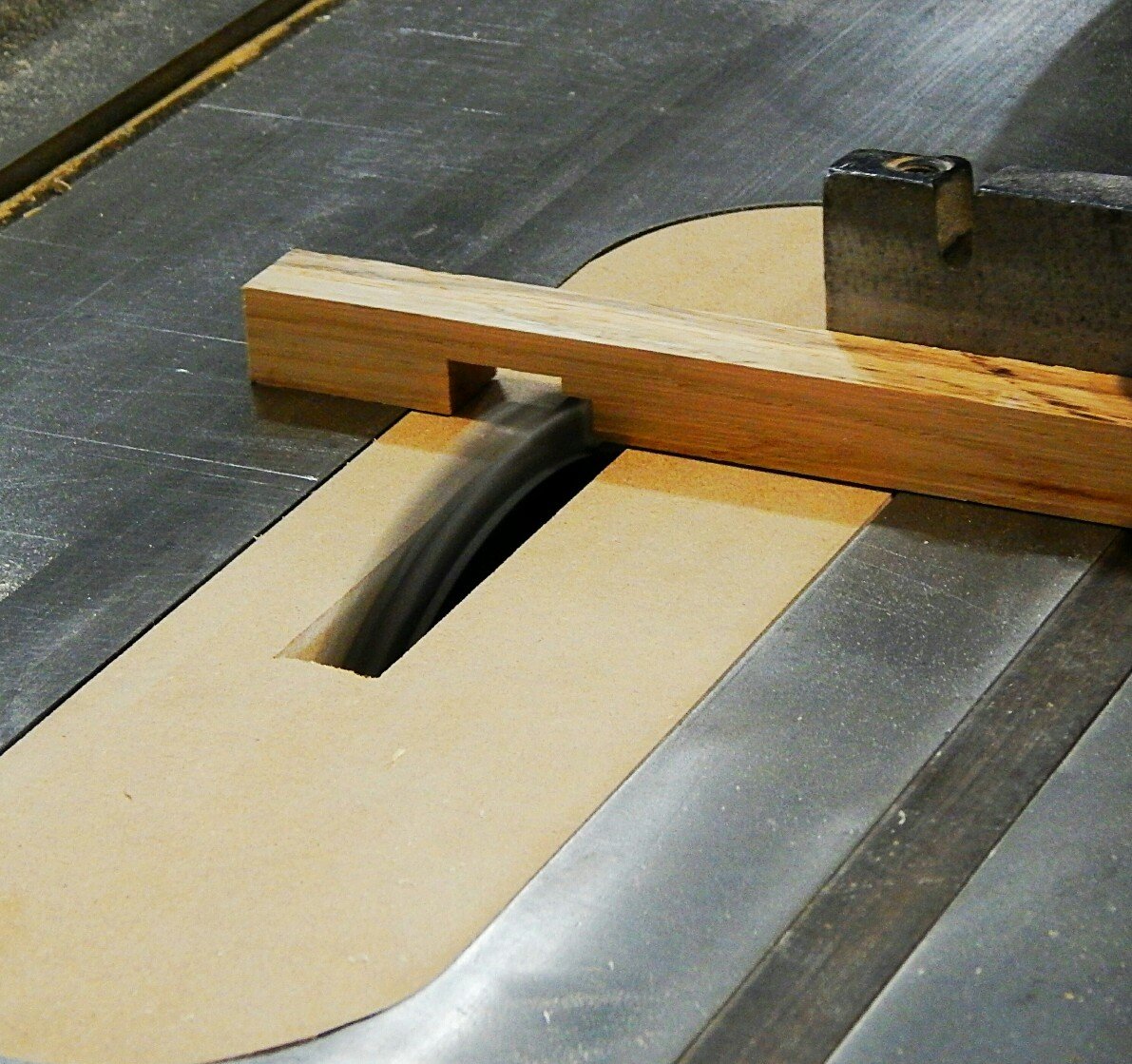

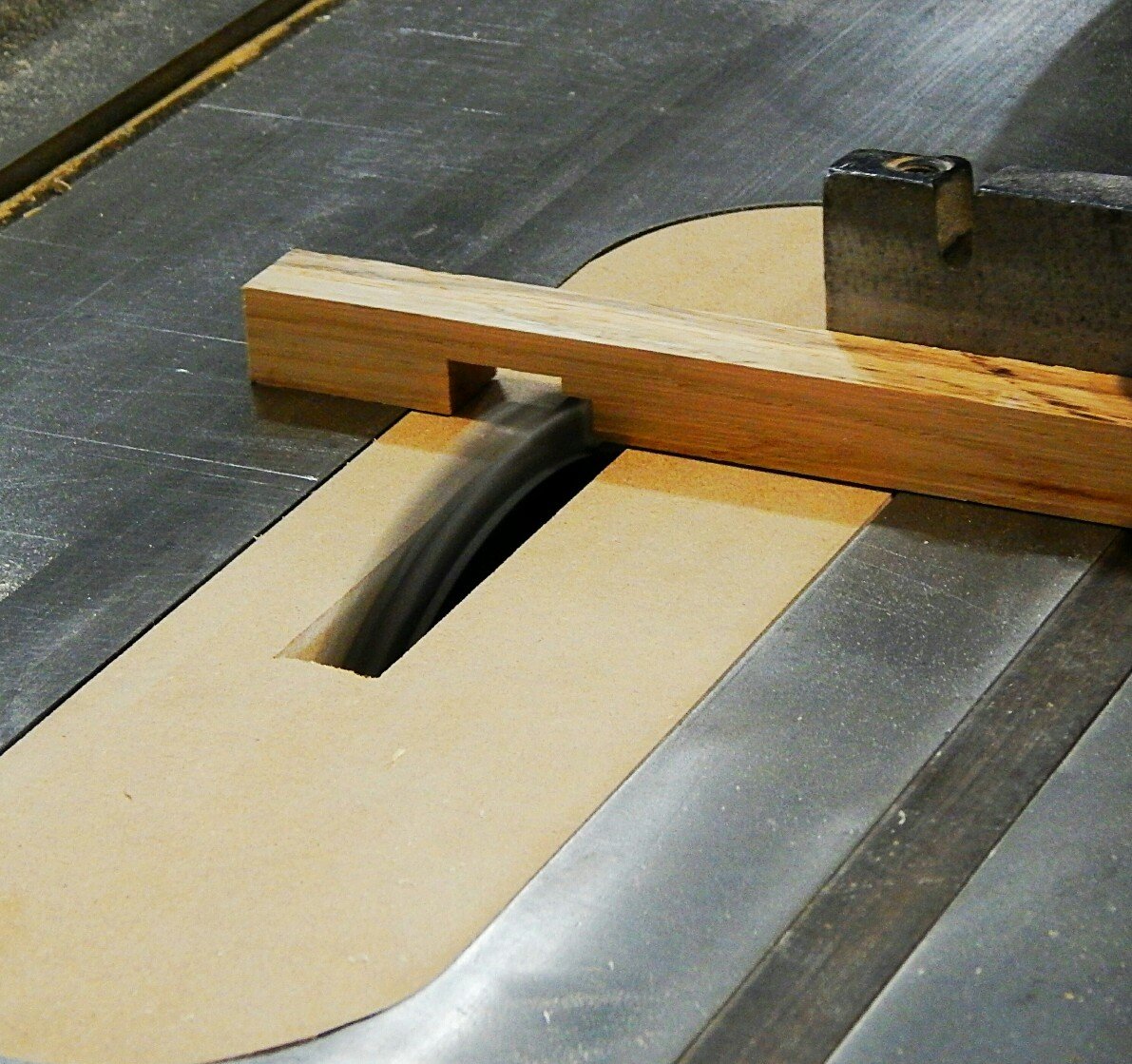

*****NOTICE TABLE SAW BLADE GUARD HAS BEEN REMOVED FOR DEMONSTRATION PURPOSES, WE DO NOT ADVISE USING YOUR TABLE SAW WITHOUT PROPER SAFETY ATTACHMENTS AND EQUIPMENT.****

If you have been following along in the series, you’ll know that we first take apart the pallets and then run the boards through a planer to get a smooth surface and remove any residue that may be present. We are going to use these boards to make a sturdy piece of lumber by gluing and clamping the individual boards together side by side first and then stacking them three high.

Once you have glued them together and they have had time to dry, run them through the table saw to get a straight edge. This should leave you with (2) 24” x 8 7/16” x 1 ½” base pieces.

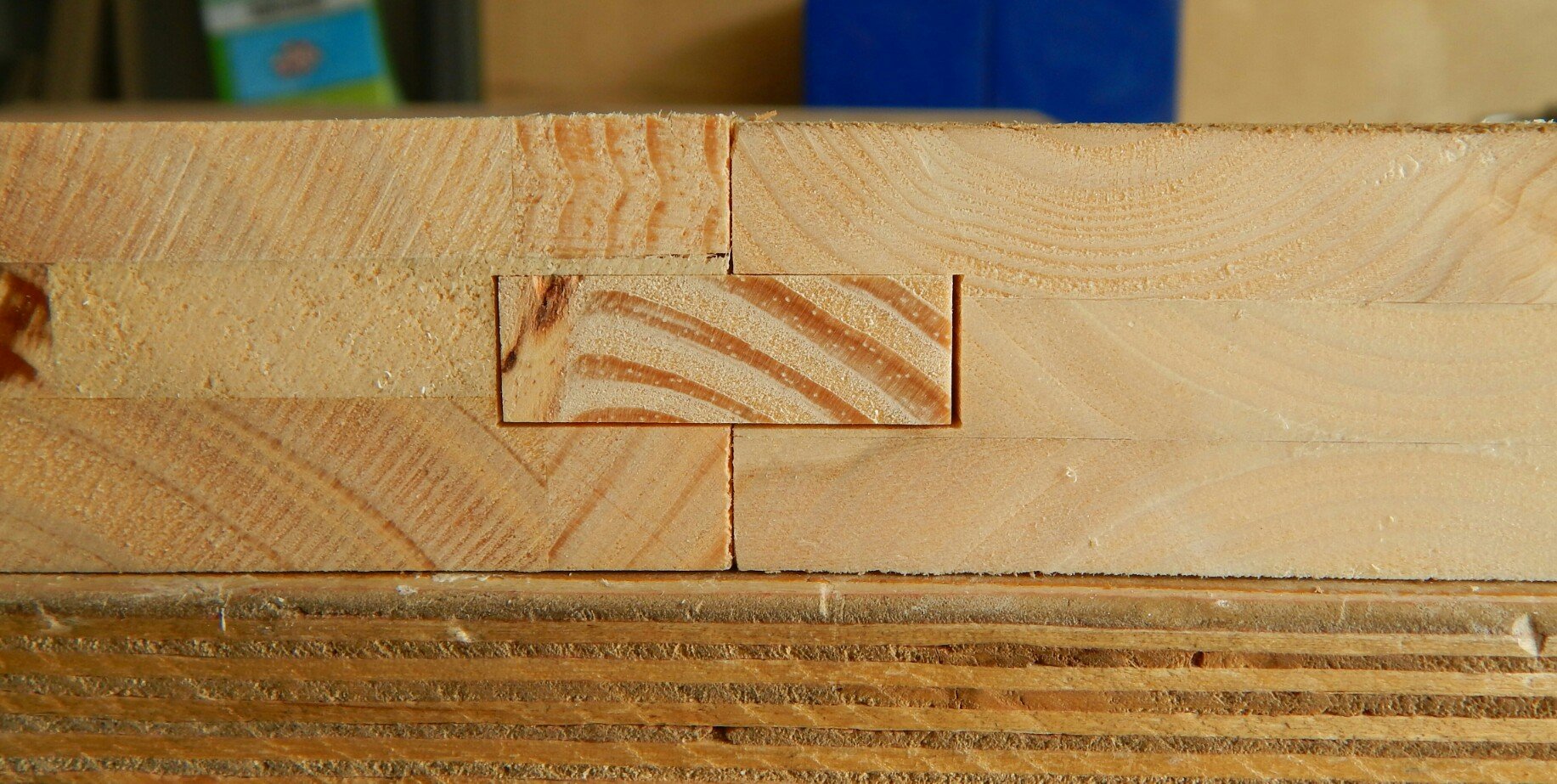

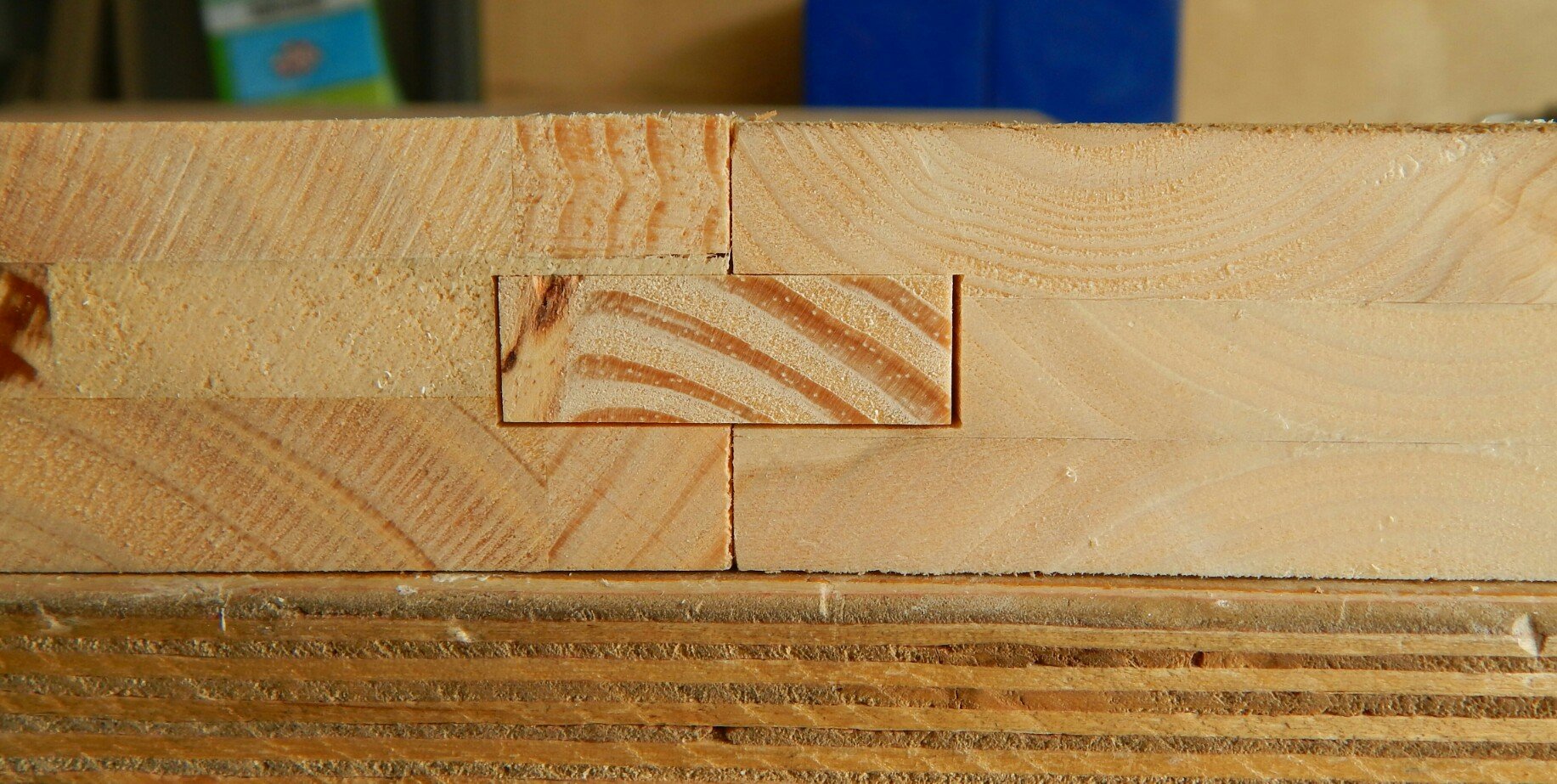

Then we are going to use a spline to connect the two pieces of lumber together, making our base. We do so by using a ½” Dado blade set to ¾” up and ½” off the fence. Run each board through on one side, leaving a perfect spacing for our spline piece to fit in snuggly. Glue and clamp.

When the piece is dry (about 24hrs) we can run it through the table saw at a 15 degree angle to make the ramp for the entrance of the hive. Make sure to leave the base measurements at 21 ¼” x 16 7/8” not including the ramp.

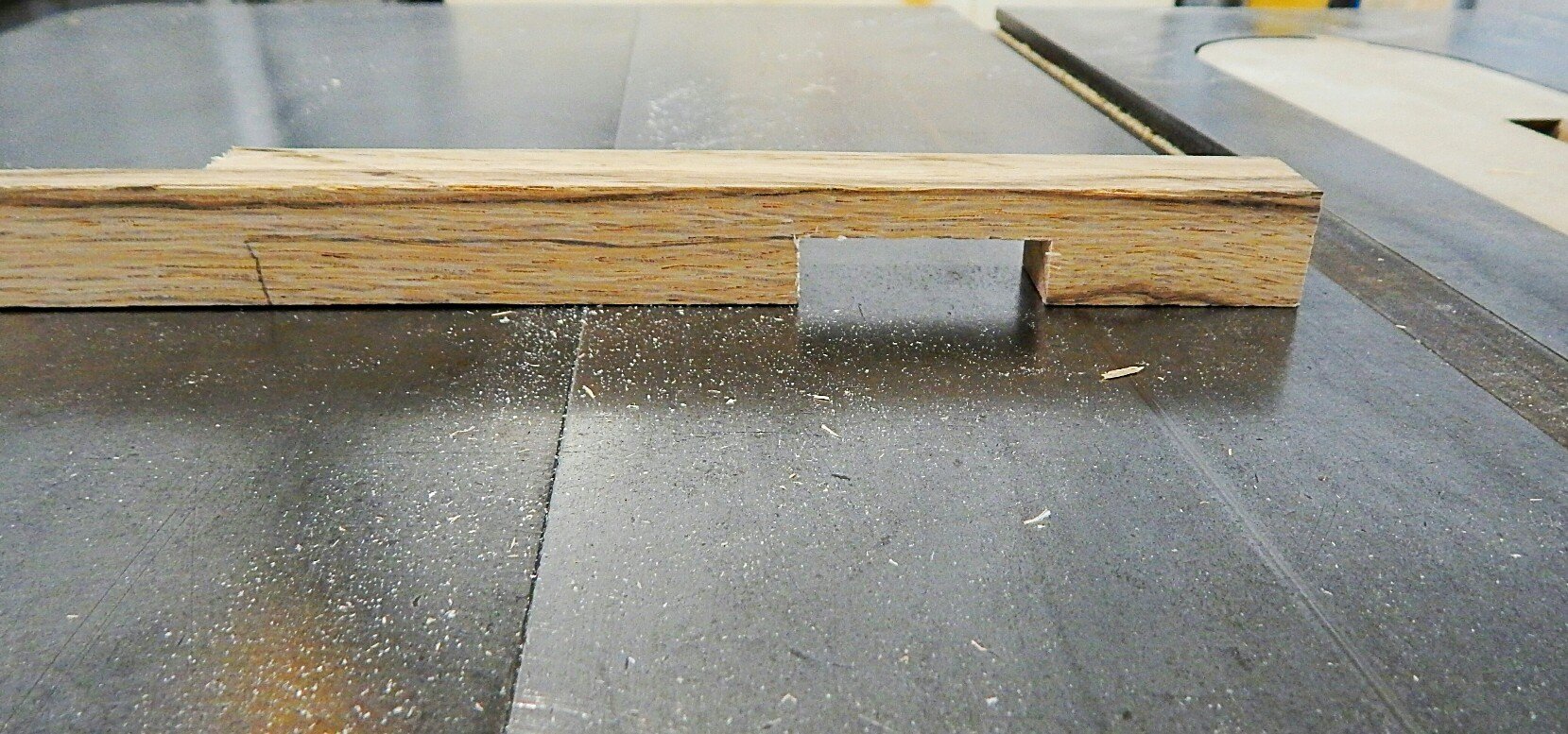

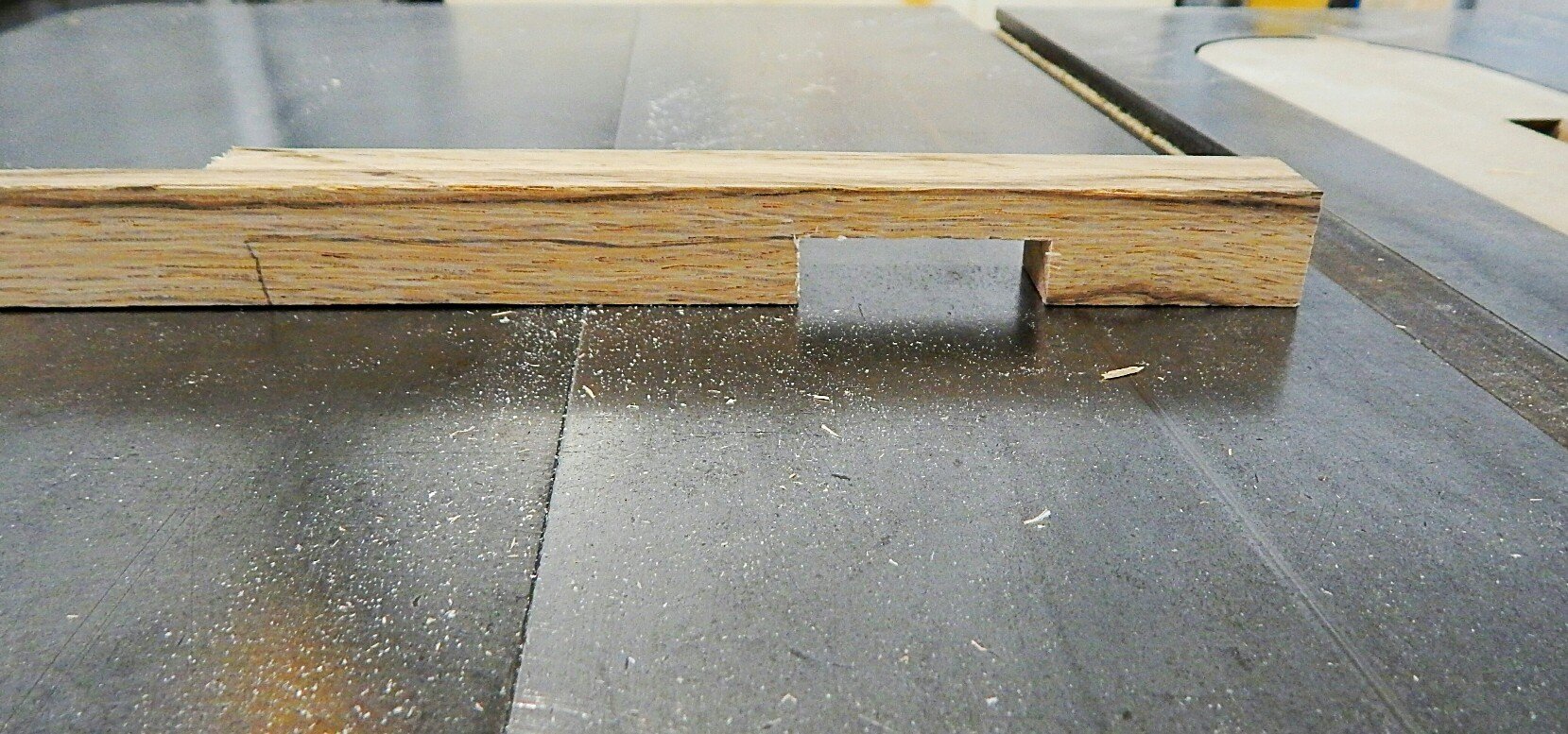

For the entrance reducer, we are trying something a bit different. Because we want to be able to control the air flow depending on the weather, we are using the dado blade to cut two different sized holes on different sides that we can flip to allow more or less air to enter the hive, removing it completely in the summer to allow more air circulation. This way the bees are spending less time trying to cool the hive and more time making honey. The measurements here are up to you depending on your weather and needs.

Next we just glue and clamp the perimeter pieces in place and it is ready for the hive box.

The base with hive box on top

The entrance reducer removed for warmer months

Entrance reducer just slides into place

Finished Bee Hive Bottom Board

Stay tuned for super boxes, the warre top and the finished beehive!

Pallet Wood Beehive Series

Thank you so much for reading,

Happy Homesteading.

All photos and content are our own. Please do not use any part of this post without our expressed permission. Thank you.