"Ceramic Water Filters for Safer and Healthier Drinking Water"

Most countries in the world especially in Southeast Asia are struggling with serious problem to safe and clean drinking water. This leads to serious diseases like cholera, diarrhea, typhoid etc. Such problem could eventually expose residents to future illnesses and increased health risks as well as deteriorate well-being. In most cases with infirmaries, patients are likely to develop infections rather than rehabilitated and cured due to lacking supply of clean water.

According to World Health Organization, roughly around 842,000 people are accounted to die each year from water diseases because of contaminated and unsafe drinking water. Out of this number of death per year, more than 40% is attributed directly to children aging less than 5 years old. The World Health Organization believes that this could be avoided if this risk factor is addressed. Therefore the challenge now is to produce safe drinking water at all cost.

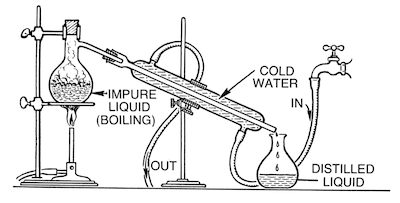

In most places, water treatment such as water distillation is practiced. Water distillation is a process which purifies water effectively and quickly at a lower and cheaper price. This process involved condenser as well as heat source. During this process, the untreated water is boiled and the water vapor is accumulated through condensing hose or coil into collecting storage. Since the boiling point of water is lower than any other contaminants, undesirable minerals and everything which are unwanted are left behind.

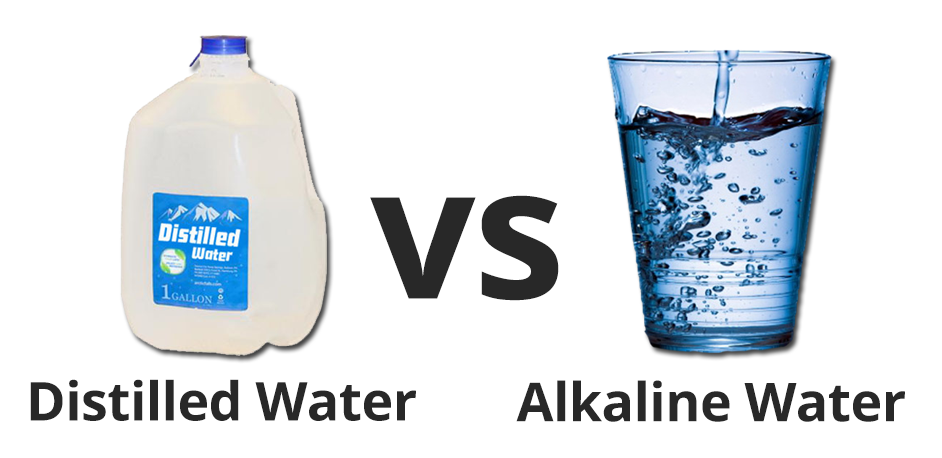

Although this efficiently kills bacteria throughout the process, the problem with this method is the acidity of the resulting treated water. Most distilled water has a pH of less than 7 and therefore it is not neutral. Our body does need as much alkaline as possible and continuous consumption of acidic water might bring serious threat in the future. The presence of carbon dioxide in the air is actually the reason for the acidity of the distilled water. That’s why neutrality of distilled water doesn’t last longer.

In the Philippines, specifically in Iligan City, one professor from Mindanao State University – Iligan Institute of Technology has been developing an alternative solution for years to be able to produce safer and healthier drinking water through the use of ceramic water filter. Although there already existed such invention in the market and in other countries, his product has unique characteristics as well as cheap manufacturing cost. The raw materials used are also abundant and are locally excavated from Lanao del Norte, Philippines.

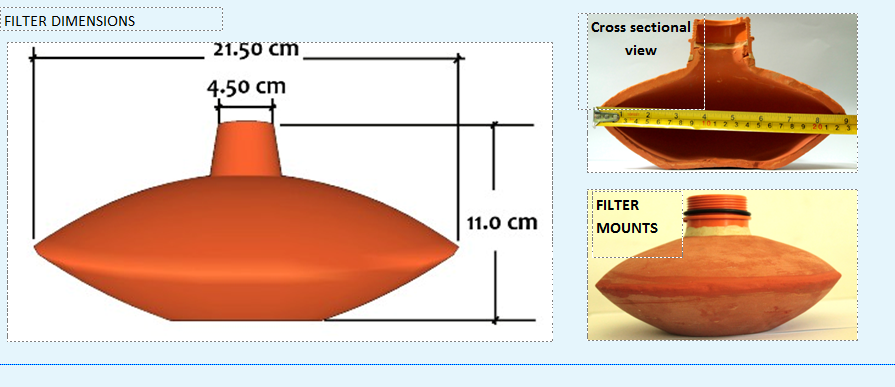

This ceramic water filter that Prof. Ibarra developed which he also called “hydria” can efficiently eliminate contaminants. Its cheap manufacturing price could also help community to obtain safe and healthy drinking water as well as effectively reduce risks in acquiring serious illnesses caused by continuous consumption of unclean water. The filter which has dimensions 11.0 cm in height, 21.50 cm in width and a 4.50 cm diameter in its mouth is a an effective and cheaper alternative to expensive and imported water filter available in the market today.

It has terra-cotta red color due to the iron impurities of the red clay. The hydria is also durable and has thickness of 6 to 10 mm depending on the slip settling duration during manufacturing process. The water filter can also be reused many times after cleaning. In fact, according to the inventors of this ceramic water filter,

Most water filters are impregnated with colloidal silver killing bacteria. The Hydria red clay ceramic water filter, on the other hand, depends on the antibacterial properties of the iron content of clay hence its sanitary and economical alternative.

The hydria is made out of red clay from Lanao del Norte, Philippines as the primary component and other local raw materials. It is has pores sizes varying from 0.2 to 5.0 microns particulate filtration efficiency. It can be able to produce 2 to 3 liters of water per hour with pH ranging from 7-8, meaning it’s basic. The filter can also effectively remove 99.9% of bacteria such as e-coli and fecal coliform.

To summarize the capabilities of hydria, it can effectively remove pathogenic bacteria. Its 0.2 to 5 microns pore size efficiently filter out rust and e-coli while alkaline minerals pass through resulting to neutral or basic water pH. It also removes chlorine thus improving odor. Heavy metals such as lead are also filtered.

Just like other ceramic water filter, hydra is produce using slip casting method. Clay minerals and other raw materials are mixed, grounded and homogenized using ball mill. The resulting slurry is then characterized to determine its properties. Gypsum mold are used in forming initial filter, subsequent air drying and preheating then follows. It is then fired at high temperature around 1000 degrees Celsius. Other techniques such as adding inorganic and other volatile material such as rice husks and saw dust are added to develop pores during firing. However, this will take thorough experimentation to achieve desirable pore size.

Today, Prof. Ibarra with the help of his students is continuing to develop this ceramic product. I am proud that I was once his student and that I was able to produce such product during my academic years in MSU-IIT. Maybe anytime soon, I will visit him and ask him to join steemit platform to share his innovation to the world if possible. I hope that you learned something from this article.

THANK YOU FOR TAKING THE TIME TO READ MY ARTICLE

Types of Portland Cement and its Individual Use in Construction

An Overview on the Manufacturing Process of Cement Industry

An Overview to Ceramics Engineering & Basic Formulation of Traditional Ceramic Body

Power Line Insulation Using Ceramic Electrical Insulators

The Manufacturing Process of Ceramic Floor Tiles & Wall Tiles

References:

http://www.who.int/mediacentre/factsheets/fs391/en/

https://www.drdavidwilliams.com/distilled-water

https://en.wikipedia.org/wiki/Ceramic_water_filter

http://www.who.int/household_water/resources/Roberts.pdf

https://www.msuiit.edu.ph/news/news-detail.php?id=514

https://www.facebook.com/HydriaCeramicWaterFilter/