"Types of Portland Cement and its Individual Use in Constructions"

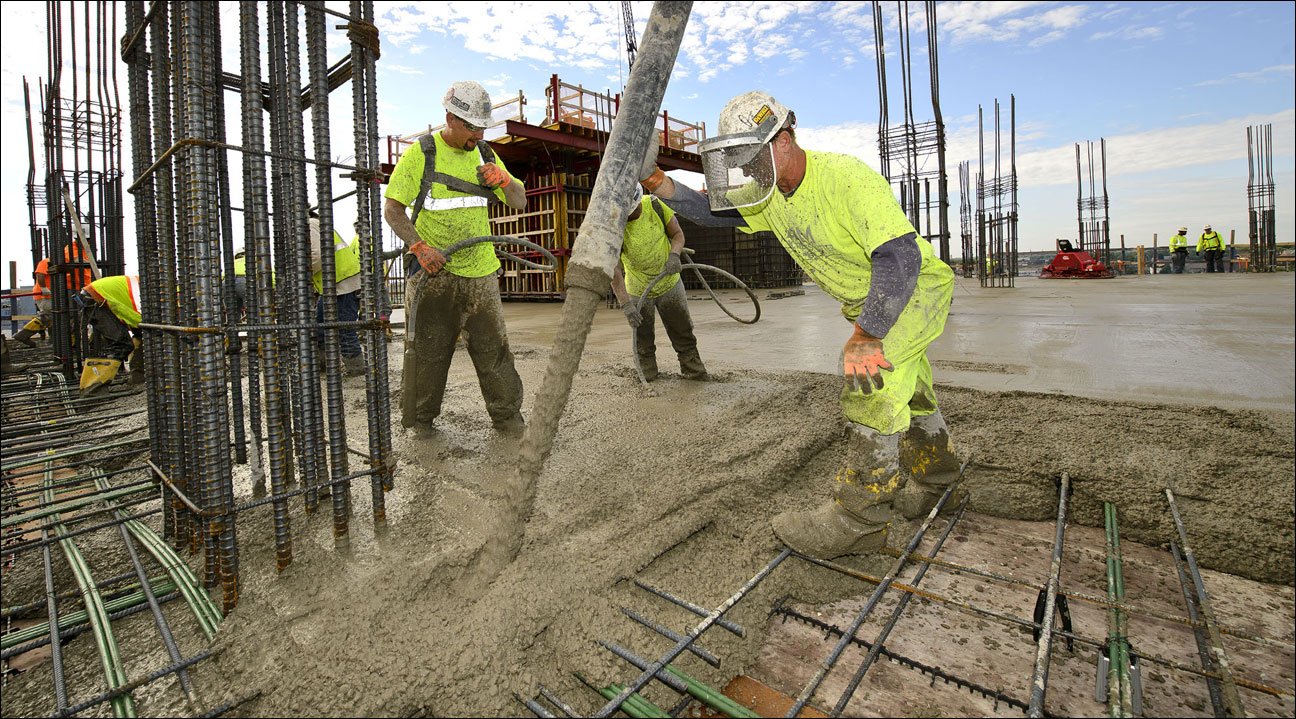

Cement has been one of the most commonly used construction material worldwide. The type of cement which has been usually utilized for constructions is the hydraulic cement called the Portland cement. There are different types of Portland cement which have different properties which are also appropriately used for different nature and characteristics of structures. You can read my recent article which provides an overview of cement manufacturing process and a brief history of Portland cement.

According to ASTM C 150 or the Standard Specification of Portland Cement, there are eight types of Portland cement with corresponding Roman numerals pertaining to its type and purpose. AASHTO M 85 also specified these cements using I to V designation. These different types of Portland cement are formulated primarily to meet several physical and chemical requirements for specific purposes. These types of Portland cement are also standardized based on the specifications of ASTM C 150, AASHTO M 85 or ACTM C 1157. But I’ll just limit the article based on the standardization of ASTM C 150 and AASHTO M 85.

All these five cements contain 75% of calcium silicate based materials with varying maturing duration or settling agent component usually gypsum. The table below shows the types of cement with its corresponding label and designation.

| Type of Cement | Designation |

|---|---|

| Type I | Normal |

| Type IA | Normal, Air-entraining |

| Type II | Moderate Sulfate Resistance |

| Type IIA | Moderate Sulfate Resistance, Air-entraining |

| Type III | High Early Strength |

| Type IIIA | High Early Strength, Air-entraining |

| Type IV | Low Heat Hydration |

| Type V | High Sulfate Resistance |

Type I Cement

This type of cement is also known as the ordinary Portland cement or the general purpose cement. This cement is generally used for almost every construction materials and to building structures which do not need and require specific special properties. It is mostly used in constructions of pavements, floors, sidewalks, buildings and households, reservoirs, masonry units, bridges etc. which do not have special condition that need to be resolved such as sulfate hazard or threat, air-entraining, heat of hydration or freezing-thawing.

Type II Cement

This type of Portland cement slightly differs with Type I or the ordinary cement through the means of slight protection against moderate sulfate outbreak. This type of cement is usually used in structures where the soil or ground waters have substantial sulfate concentration which is higher than the customary where ordinary cement could still be utilized. However, this concentration is limited not to exceed severe level which could result severe damage to concrete structure.

This cement usually contains not more than 8% of tricalcium aluminate – the component which is responsible for the initial settling duration and strength. This type of cement generates slower heat rate than of type I cement and could also be used for concrete directly exposed to seawater. Although the sulfates in sea could attack the concrete, the presence of chlorides restrains it. It is generally used in making very thick bridge support and dams.

Type III Cement

The type III Portland cement are cements used for constructions or structures which need to possessed an early strength usually at week or less. The physical and chemical properties of this cement is somewhat similar to type I cement but differ primarily in their powder grain size. This type of cements is usually used on structures which need to be put to service as quickly as possible. In other words, this cement is used when early strength and curing time is shortened to its lowest possible option.

Examples for the utilizations of this type of cement include cold weather concreting which significantly reduce the rate of hydration, public roads to minimize traffic congestions and precast concrete for rapid form removal. There are also higher-cement content of type I cement which could be used to gain early strength but type III is more economical as the latter is design to develop early strength more quickly than type I cement.

Type IV Cement

This type of cement is designed to minimize the rate and the amount of heat generated from hydration which also means that the strength of the concrete is developed at slower rate than those of type I cements. This type of cement is usually used in construction of huge concrete structures such as dams (where temperature could) rise to minimize hardening. This slow heat rate generated during hydration limits the concrete elements’ inner temperature which could result in uneven expansion which could result to cracking and damage at early stage. This type of cement is seldom used today as its specific properties could be achieved by blended cement.

Type V Cement

Type V cements are primarily designed with advanced anti sulfate properties than type II cement. This cement is used in making concrete which is exposed or directly in contact with severe sulfate concentration or where soil and ground water possessed severe sulfate threat. The type V cement has slower strength development rate than type I cement and its high sulfate resistance is attributed to its low tricalcium aluminate content which is not exceeding to 5%. However, just like the other Portland cements, type V cement is not resistant to acid attack or any other highly corrosive substances.

Air-entraining Portland Cements

Air-entraining cements specifications correspond to ASTM types I, II and III compositions except for its air-entraining additives which are initially added during its manufacturing process when it’s still clinker nodes. These cements are designed with improved freezing resistance and thawing. With these cements, concrete would have well-distributed and completely separated air bubbles. Usually, air-entraining cements are available only for areas with winter or snow weather is experienced.

An Overview on the Manufacturing Process of Cement Industry

An Overview to Ceramics Engineering & Basic Formulation of Traditional Ceramic Body

Power Line Insulation Using Ceramic Electrical Insulators

The Manufacturing Process of Ceramic Floor Tiles & Wall Tiles

Traditional Ceramic Methods in Making Earthenware, Stoneware and Porcelain

References:

http://www.imcyc.com/biblioteca/ArchivosPDF/Tipos%20de%20cemento/Types%20of%20Portland%20Cement.pdf

http://civil.emu.edu.tr/courses/civl284/3%20Cements.pdf

http://iti.northwestern.edu/cement/monograph/Monograph3_8.html